Mixer for concrete and similar mixtures

A mixture and concrete technology, which is applied in the direction of mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve problems such as complex and difficult operations, difficult operation of lifting equipment, and endangering the safety of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

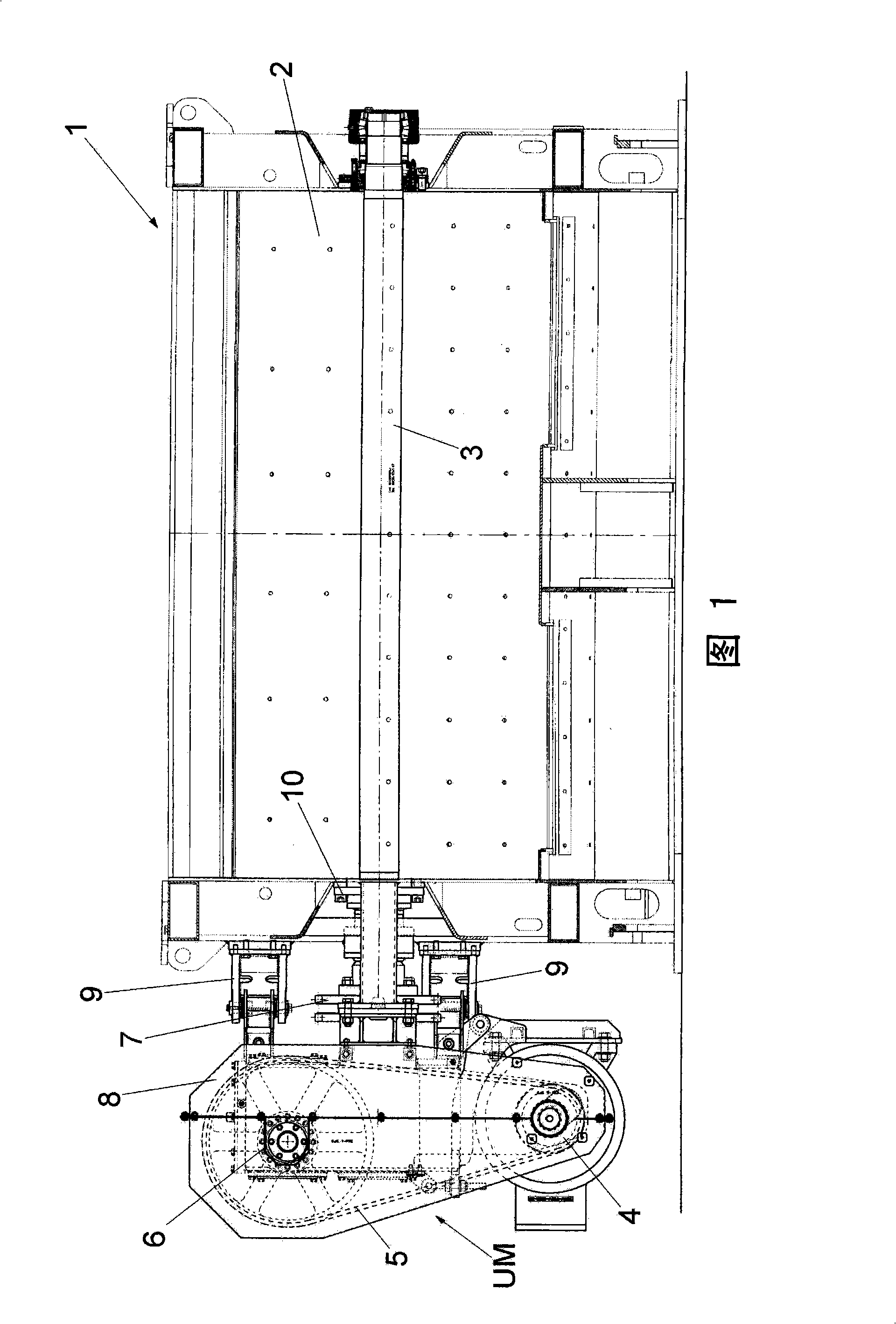

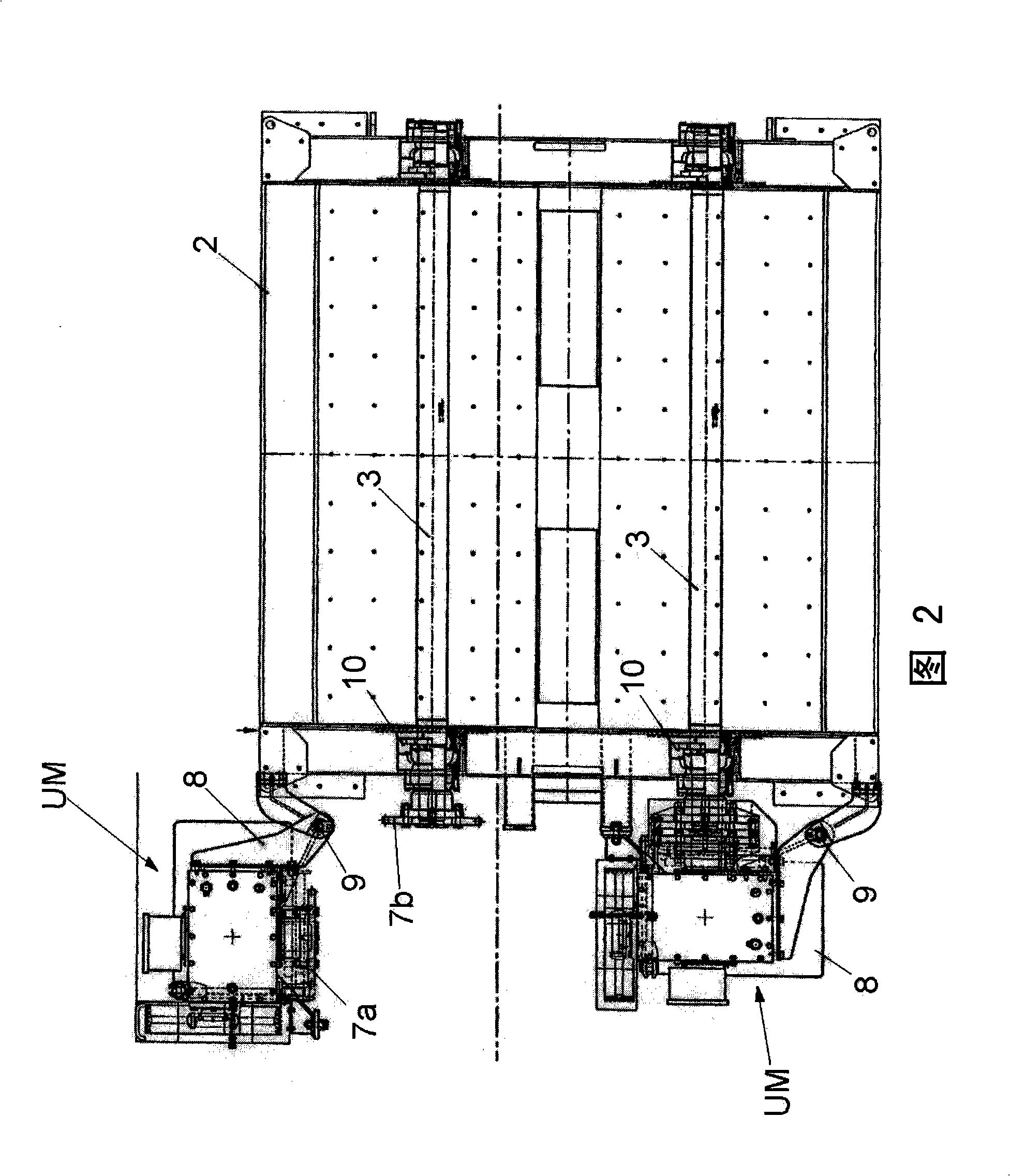

[0036] According to the above illustration, the conventional component of the mixer 1 is a rectangular mixing tank 2 equipped with one or several rotating mixing shafts 3 supported horizontally between two transverse sides.

[0037] Each agitator shaft 3 is driven by a corresponding motor system UM consisting of an electric motor 4 connected by a conveyor belt 5 to a gear motor 6 which in turn is connected to the top end of the corresponding agitator shaft 3 via a joint 7 .

[0038] All the components of the above-mentioned engine system UM are fixed to the same frame 8 , which is fixed on the outside of the load-bearing side of the mixing tank 2 by one or several fasteners, namely hinges 9 .

[0039] As mentioned above, the frame 8 and the parts of the engine system UM can be shifted and moved from the working position (in close contact with the side of the mixing tank) to the non-working position (deviating from the above-mentioned side) by using the hinge 9, so that the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com