Front structure of vehicle

A front structure and automobile technology, which is applied to the superstructure, superstructure sub-assemblies, vehicle components, etc., can solve the problems of smaller opening area, reduced radiator capacity, adverse effects on engine cooling performance, etc., to ensure rigidity, The effect of reducing load and promoting bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

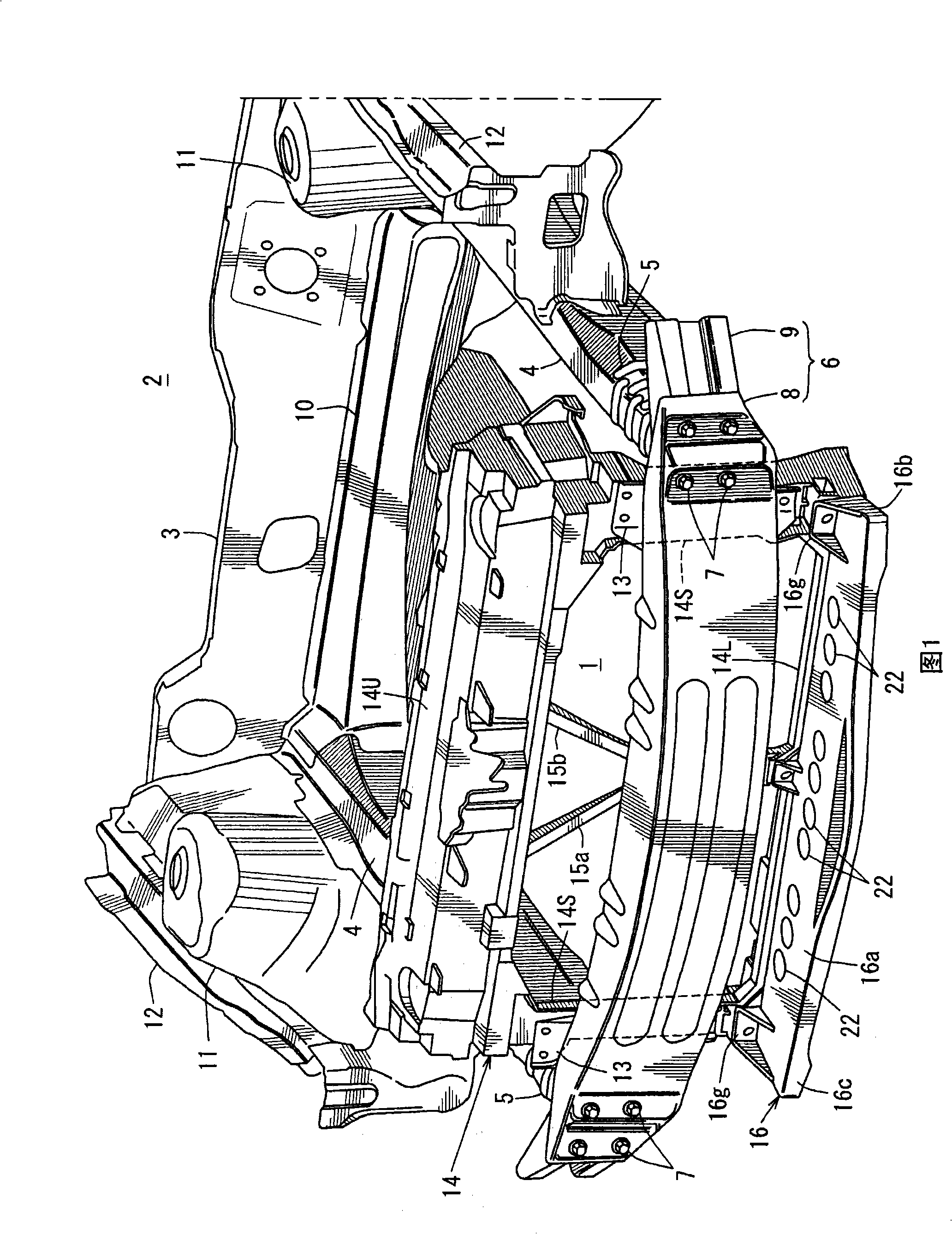

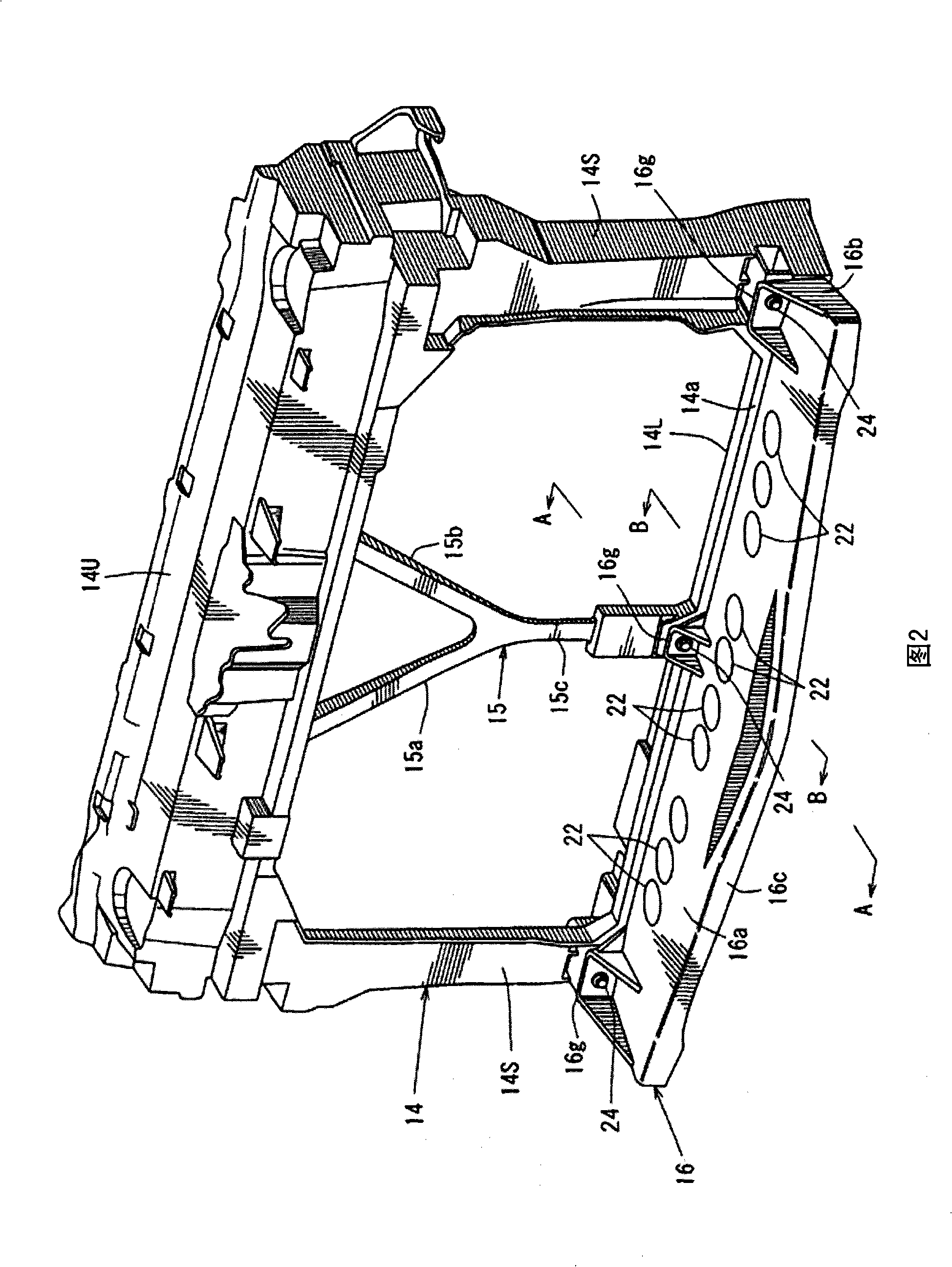

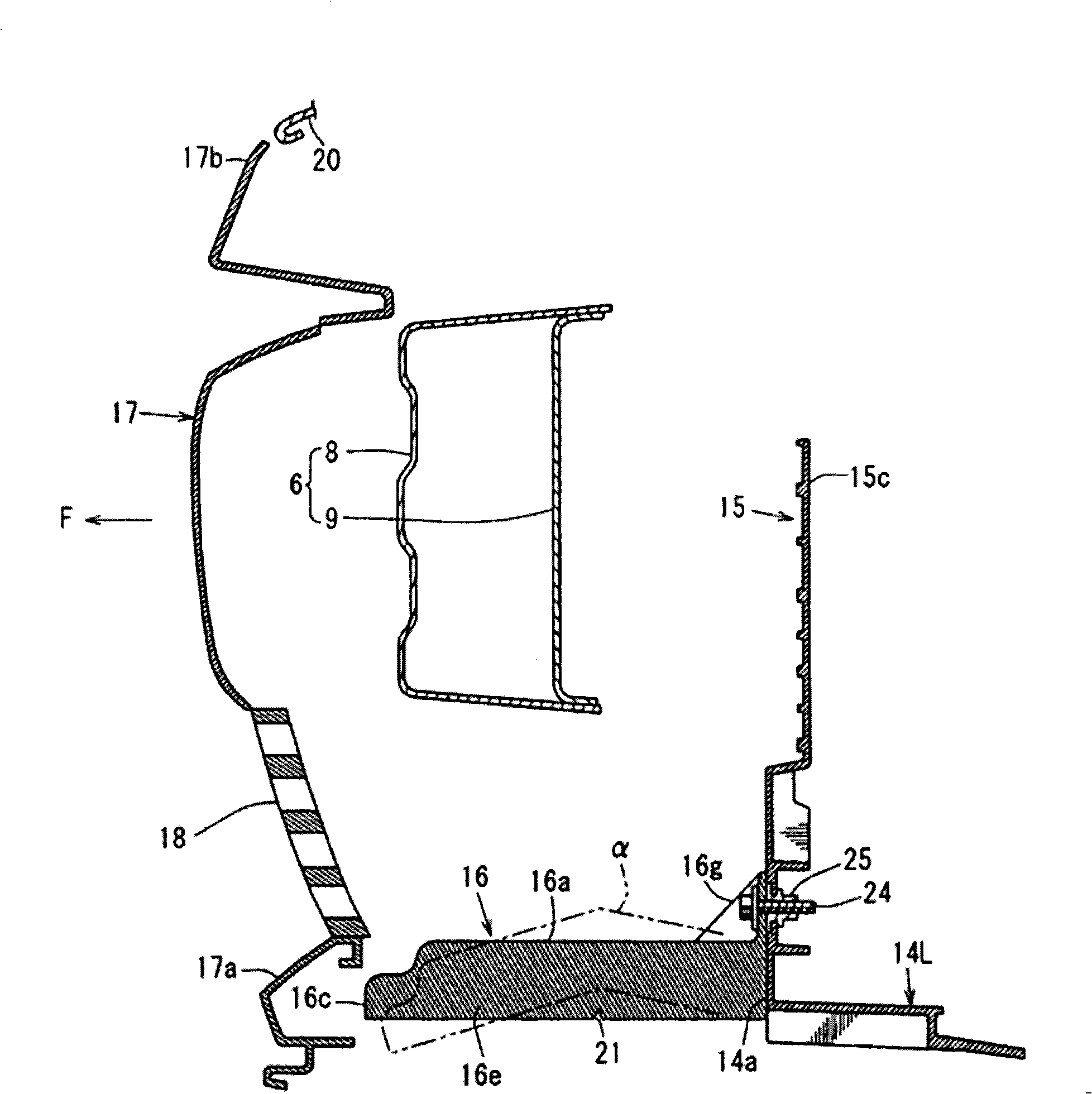

[0048] An embodiment of the present invention will be described in detail below with reference to the drawings.

[0049] FIG. 1 is a perspective view showing the front structure of an automobile. The front structure of the automobile shown in this figure includes a dash panel lower part 3 (dash panel) that separates the engine room 1 and the vehicle compartment 2 behind it in the front-to-rear direction, and a dash panel lower part 3 arranged on the dash panel lower part 3 The front side members 4 , 4 extend in the vehicle front-rear direction on the left and right sides of the engine room 1 .

[0050] Energy absorbing portions 5 , 5 having uneven wall surfaces are integrally formed on the front portions of the pair of left and right front side members 4 , 4 , and the energy absorbing portion 5 absorbs loads during a frontal collision of the vehicle. In the present embodiment, by providing the above-mentioned energy absorbing parts 5, 5, the crash can (crash can) used normall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com