Antiskid glass and method of manufacture

A manufacturing method and glass technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of difficult cleaning, easy storage of dust, low friction coefficient, etc., and achieve high static friction coefficient, Increased surface roughness for easy daily cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

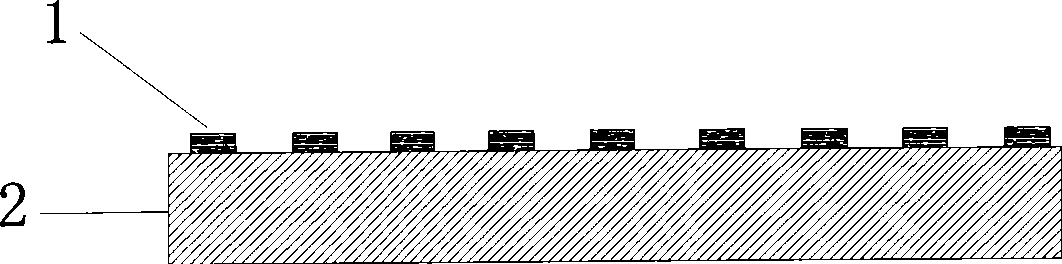

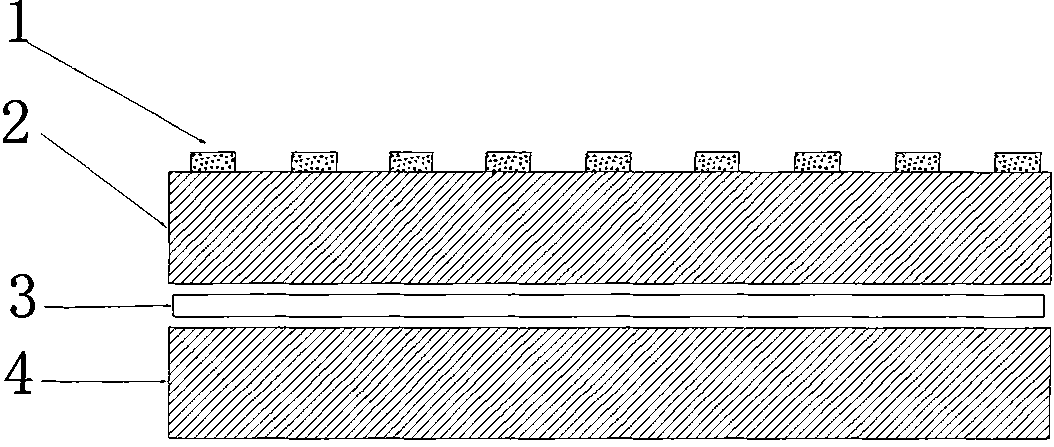

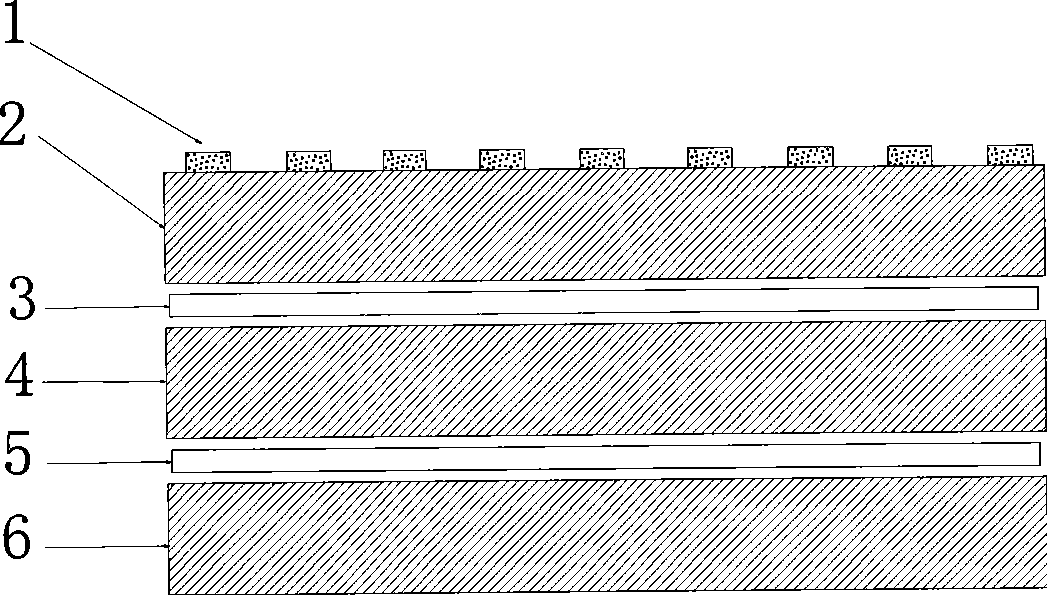

[0022] figure 1 Schematic diagram of the structure of one embodiment of the shown anti-skid glass. Such as figure 1 As shown, the anti-slip glass of the present invention is composed of a colored or transparent glass substrate 2 and an anti-slip layer 1 . The anti-slip layer 1 is formed on the surface of the glass substrate through high-temperature sintering with sand grains and glazes of various colors. The weight percentages of the glaze and the sand in the anti-slip layer are: 50%-90% of the glaze and 10%-50% of the sand. The thickness of the anti-skid layer after high temperature sintering is about 75 μm-1 mm.

[0023] The glass substrate 1 can be semi-tempered or tempered glass, and the stress is between 25Mpa-200Mpa. The thickness of the glaze varies slightly depending on how it is applied. For example, the thickness of the glaze coated on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com