Interior floor paint for building and preparation method of interior floor paint

A technology for buildings and floors, applied in the direction of coating, etc., can solve the problems of insufficient coating adhesion, easy layer peeling, poor wear resistance, etc., achieve good wear resistance, avoid expansion, deformation or decay, and adhere to strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

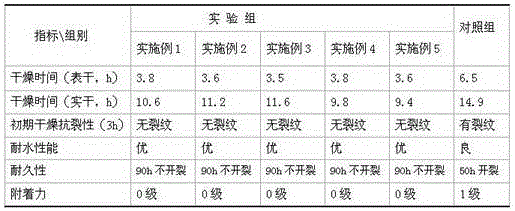

Examples

Embodiment 1

[0043] Example 1 A building interior floor coating prepared from the following raw materials (22kg per part): 23.0 parts of phenolic resin, 4.9 parts of masonry cement, 3.2 parts of water glass, 4.9 parts of kaolin, 4.3 parts of organic bentonite, wollastonite 2.8 parts, 3.2 parts of talc, 2.7 parts of magnesium trisilicate, 2.3 parts of glycerol, 2.5 parts of lignocellulose, 2.1 parts of emulsified silicone oil, 1.6 parts of sodium carboxymethyl cellulose, and 1.4 parts of tung oil.

[0044] A kind of building interior floor coating preparation step is as follows:

[0045] (1) Put wollastonite and magnesium trisilicate in a stone crusher, grind for 30 minutes, transfer to an ultrafine grinder, add phenolic resin, mechanically grind for 20 minutes, pour into a mixer, add water (the amount is phenolic resin 8 times the mass) and stir for 20 minutes, add water glass, continue to stir for 10 minutes, heat to 45°C, and keep warm for 40 minutes;

[0046] (2) Put glycerol in an e...

Embodiment 2

[0051] Example 2 A building interior floor coating prepared from the following raw materials (13kg per part): 28.0 parts of phenolic resin, 6.2 parts of masonry cement, 3.8 parts of water glass, 5.8 parts of kaolin, 4.9 parts of organic bentonite, wollastonite 3.3 parts, 3.7 parts of talcum powder, 3.2 parts of magnesium trisilicate, 2.8 parts of glycerol, 3.2 parts of lignocellulose, 2.6 parts of emulsified silicone oil, 2.2 parts of sodium carboxymethyl cellulose, and 1.8 parts of tung oil.

[0052] A kind of building interior floor coating preparation step is as follows:

[0053] (1) Put wollastonite and magnesium trisilicate in a stone crusher, grind for 40 minutes, transfer to an ultrafine grinder, add phenolic resin, mechanically grind for 30 minutes, pour into a mixer, add water (the amount is phenolic resin 12 times the mass) and stir for 30 minutes, add water glass, continue to stir for 15 minutes, heat to 50°C, and keep warm for 50 minutes;

[0054] (2) Put glycer...

Embodiment 3

[0059] Example 3 A building interior floor coating prepared from the following raw materials (15kg per part): 25.0 parts of phenolic resin, 5.4 parts of masonry cement, 3.4 parts of water glass, 5.2 parts of kaolin, 4.5 parts of organic bentonite, wollastonite 3.0 parts, 3.4 parts of talcum powder, 2.9 parts of magnesium trisilicate, 2.5 parts of glycerin, 2.7 parts of lignocellulose, 2.3 parts of emulsified silicone oil, 1.8 parts of sodium carboxymethyl cellulose, and 1.5 parts of tung oil.

[0060] A kind of building interior floor coating preparation step is as follows:

[0061] (1) Put wollastonite and magnesium trisilicate in a stone crusher, grind for 33 minutes, transfer to an ultrafine grinder, add phenolic resin, mechanically grind for 23 minutes, pour into a mixer, add water (the amount is phenolic resin 9 times the mass) and stir for 23 minutes, add water glass, continue to stir for 12 minutes, heat to 46°C, and keep warm for 43 minutes;

[0062] (2) Put glycero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com