A kind of durable floor coating and preparation method thereof

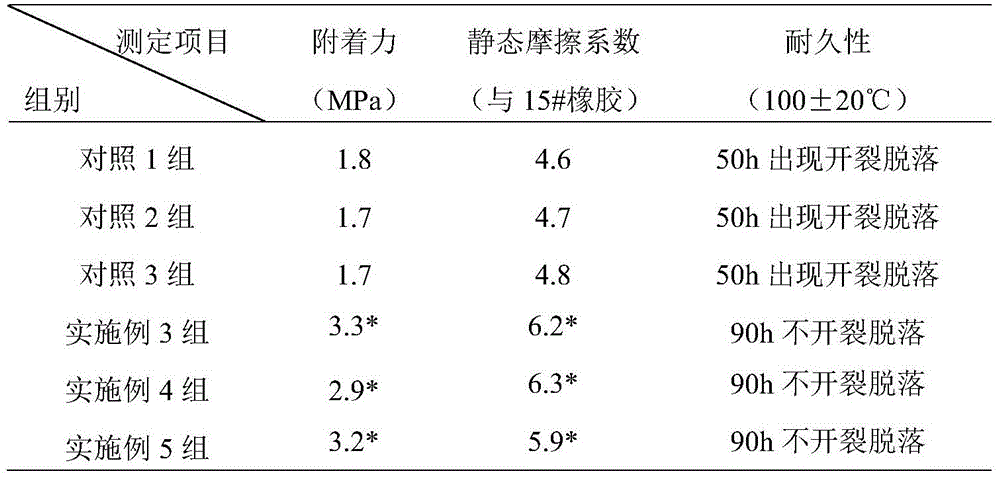

A floor and coating technology, applied in polyester coatings, polyamide coatings, coatings, etc., can solve the problems of insufficient coating adhesion, short service life, over-slip coating, etc., and achieve excellent durability, long service life, The effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Party:

[0019] 20g polyamide resin, 10g alkyd resin, 2g sodium polyacrylate, 2g zinc stearate, 1g sodium pyrophosphate, 2g thiodiethanol, 0.5g pigment, 1g talcum powder.

[0020] Preparation:

[0021] (1) Put the alkyd resin and thiodiethanol in a container, add a certain amount of deionized water, disperse at a high speed of 4000r / min for 30 minutes, and obtain the primary emulsion;

[0022] (2) Add sodium polyacrylate, zinc stearate, sodium pyrophosphate and pigments to the above-mentioned primary emulsion, and disperse at a high speed of 3600r / min for 20 minutes to obtain a colored paste;

[0023] (3) Make polyamide resin into emulsion, mix with talcum powder and the above-mentioned color paste, disperse at low speed of 800r / min for 10 minutes, and the product is obtained.

[0024] The degree of polycondensation of the polyamide resin is 50.

Embodiment 2

[0026] Party:

[0027] 20g of polyamide resin, 20g of alkyd resin, 10g of sodium polyacrylate, 8g of zinc stearate, 5g of sodium pyrophosphate, 6g of thiodiethanol, 0.9g of pigment, and 7g of glass powder.

[0028] Preparation:

[0029] (1) Put alkyd resin and thiodiethanol in a container, add a certain amount of deionized water, and disperse at a high speed of 6000r / min for 40 minutes to obtain primary emulsion;

[0030] (2) Add sodium polyacrylate, zinc stearate, sodium pyrophosphate and pigments to the above-mentioned primary emulsion, and disperse at a high speed of 4200r / min for 30 minutes to obtain a colored paste;

[0031] (3) Make polyamide resin into emulsion, mix with glass powder and the above-mentioned color paste, and disperse at a low speed of 1200r / min for 20 minutes to obtain the product.

[0032] The degree of polycondensation of the polyamide resin is 70.

Embodiment 3

[0034] Party:

[0035] 20g of polyamide resin, 15g of alkyd resin, 6g of sodium polyacrylate, 5g of zinc stearate, 3g of sodium pyrophosphate, 4g of thiodiethanol, 0.7g of pigment, and 4g of diatomaceous earth.

[0036] Preparation:

[0037] (1) Put the alkyd resin and thiodiethanol in a container, add a certain amount of deionized water, disperse at a high speed of 5000r / min for 35 minutes, and obtain the primary emulsion;

[0038] (2) Add sodium polyacrylate, zinc stearate, sodium pyrophosphate and pigments to the above-mentioned primary emulsion, and disperse at a high speed of 3900r / min for 25 minutes to obtain a colored paste;

[0039] (3) Make polyamide resin into an emulsion, mix it with diatomaceous earth and the above-mentioned color paste, and disperse at a low speed of 1000r / min for 15 minutes to obtain the product.

[0040] The degree of polycondensation of the polyamide resin is 60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com