Rail lofting ruler and measuring locating device thereof

A technology for positioning equipment and rails, which is applied to rails, measuring instruments, rail maintenance and other directions, can solve the problems of inability to determine the specific position and line direction of the rails, and inability to directly realize the lofting function, and achieve the effect of good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

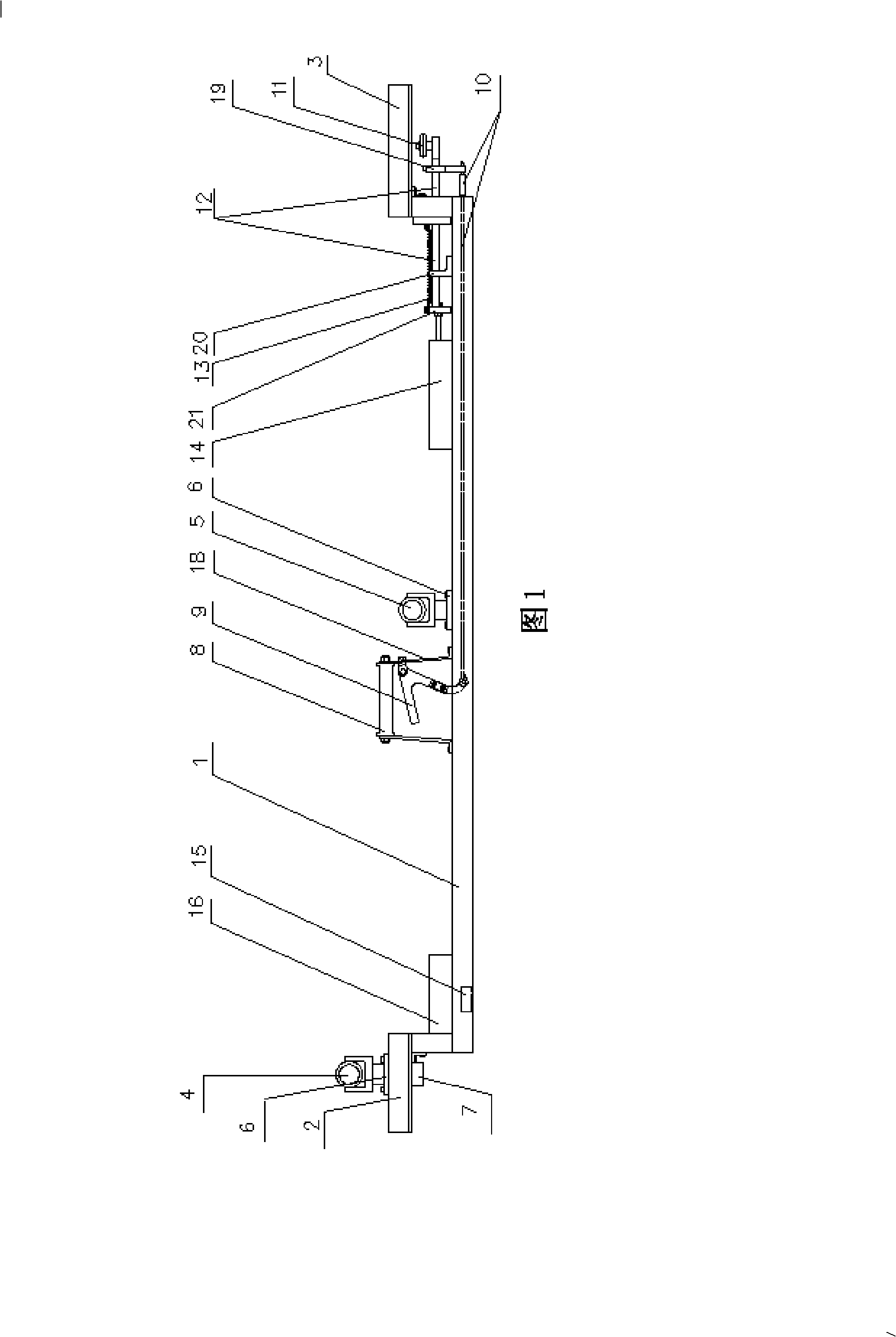

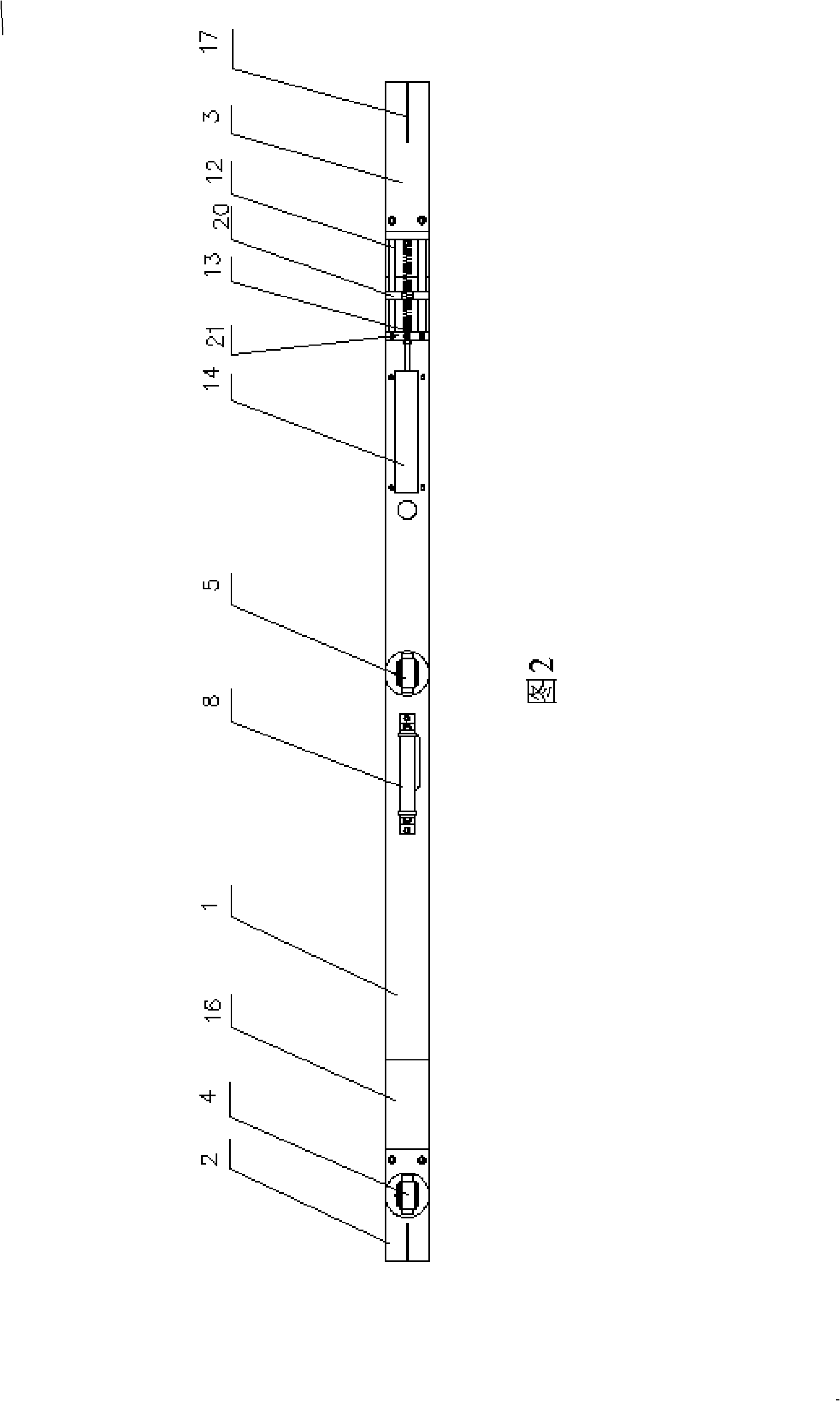

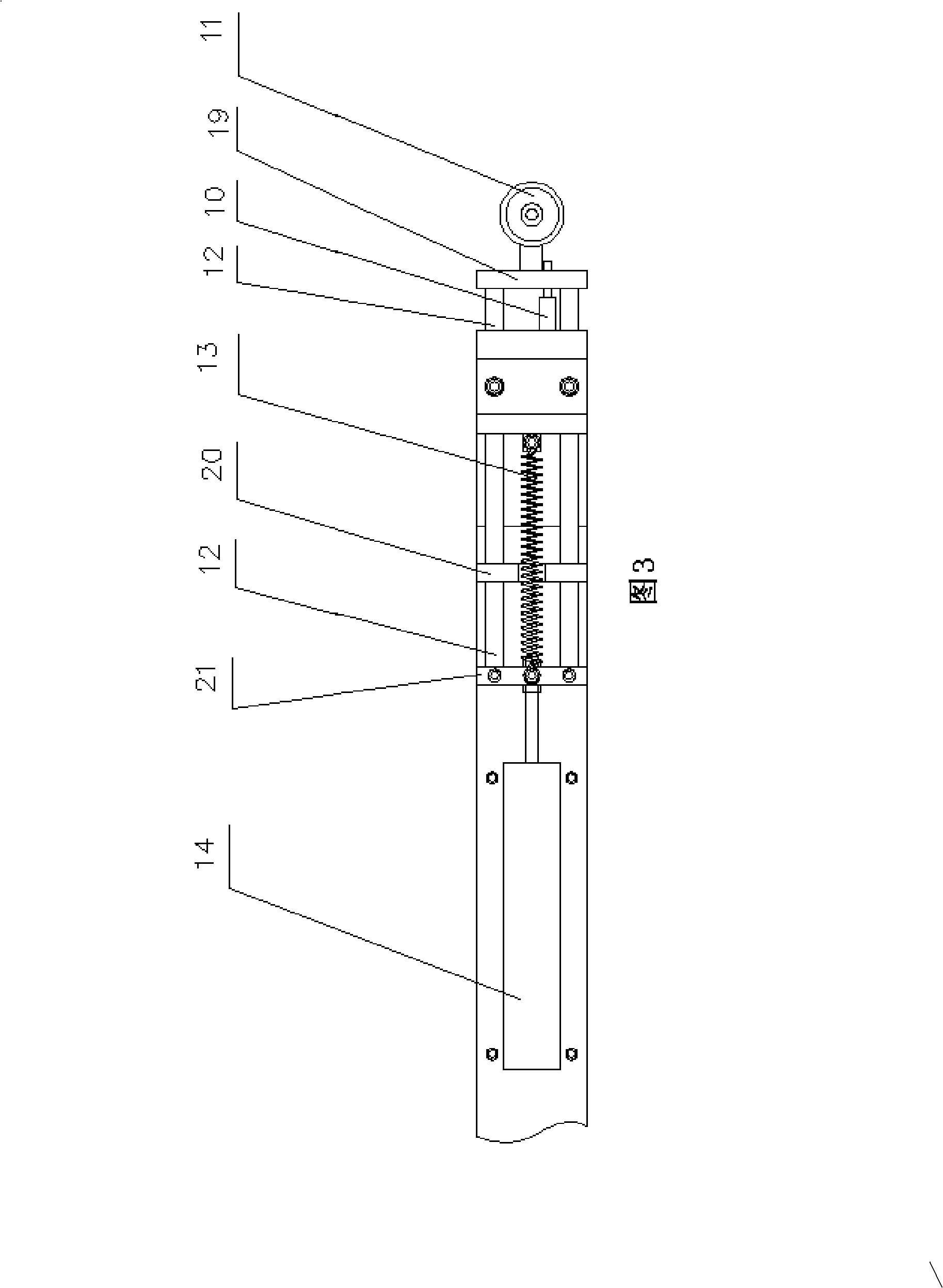

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] As shown in Fig. 1, Fig. 2 and Fig. 3, the present invention mainly consists of main beam 1, left rail beam 2, right rail beam 3, rail top prism 4, center prism 5, tight pulley 7, brake handle 9, pull rod 10 , Measuring wheel 11, measuring wheel support bar 12, extension spring 13, gauge sensor 14, inclination sensor 15 and electrical control box 16 are made up.

[0014] The left rail beam 2 and the right rail beam 3 are processed into a whole with the main beam 1, the rail top prism 4 and the center prism 5 are respectively inserted in the respective prism holders 6, and the rail top prism 4 and the tight wheels 7 are respectively arranged on the left rail beam On the upper and lower sides of 2, the rail top prism 4 is located directly above the tight wheel 7 and the geometric relationship with the left rail beam 2 and the tight wheel 7 is fixed, and the geometric r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com