Method for extracting lycium barbarum polysaccharide through cooperation of ultrasonic waves and surfactant

A technology of surfactants and Lycium barbarum polysaccharides, which is applied in the field of extracting natural product active substances, can solve the problems of reducing the yield of polysaccharides, multiple extractions, and low extraction rates, and achieve good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

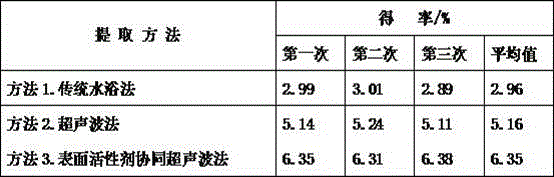

Image

Examples

Embodiment 1

[0024] A method for extracting Lycium barbarum polysaccharides with ultrasonic waves and surfactants, comprising the steps of:

[0025] Step 1, drying wolfberry slag, pulverizing with a pulverizer to obtain wolfberry powder;

[0026] Step 2, add an aqueous solution of a surfactant with a mass percent concentration of 0.8% to the wolfberry powder obtained in step 1 at a mass volume ratio of 1:20 (g / ml), soak at room temperature for 3 hours, and obtain a feed solution;

[0027] Step 3, ultrasonically extracting the feed liquid obtained in step 2, ultrasonically extracting wolfberry residue 3 times at an ultrasonic power of 200w, each time for 20 minutes, and combining the filtrates to obtain a wolfberry polysaccharide extract;

[0028] In step 4, the wolfberry polysaccharide extract obtained in step 3 is filtered through a 250-mesh 5-layer nylon mesh to remove wolfberry seeds and insoluble matter;

[0029] In step 5, the wolfberry polysaccharide extract after removing wolfberry...

Embodiment 2

[0038] A method for extracting Lycium barbarum polysaccharides with ultrasonic wave and surfactant, is characterized in that: it comprises the steps:

[0039] Step 1, drying wolfberry slag, pulverizing with a pulverizer to obtain wolfberry powder;

[0040] Step 2, add an aqueous solution of a surfactant with a mass percentage concentration of 1.0% to the wolfberry powder obtained in step 1 at a mass volume ratio of 1:25 (g / ml), soak at room temperature for 4 hours, and obtain a feed solution;

[0041] Step 3, ultrasonically extracting the feed liquid obtained in step 2, ultrasonically extracting wolfberry residue 3 times at an ultrasonic power of 250w, each time for 25min, and combining the filtrates to obtain a wolfberry polysaccharide extract;

[0042] In step 4, the wolfberry polysaccharide extract obtained in step 3 is filtered through a 300-mesh 5-layer nylon mesh to remove wolfberry seeds and insoluble matter;

[0043] In step 5, the wolfberry polysaccharide extract aft...

Embodiment 3

[0052] A method for extracting Lycium barbarum polysaccharides with ultrasonic wave and surfactant, is characterized in that: it comprises the steps:

[0053] Step 1, drying wolfberry slag, pulverizing with a pulverizer to obtain wolfberry powder;

[0054] Step 2, add an aqueous solution of a surfactant with a mass percent concentration of 1.2% to the wolfberry powder obtained in step 1 at a mass volume ratio of 1:30 (g / ml), soak at room temperature for 5 hours, and obtain a feed solution;

[0055] Step 3, ultrasonically extracting the feed liquid obtained in step 2, ultrasonically extracting wolfberry powder 3 times at an ultrasonic power of 300w, each time for 30min, combining the filtrates to obtain a wolfberry polysaccharide extract;

[0056] In step 4, the wolfberry polysaccharide extract obtained in step 3 is filtered through a 350-mesh 5-layer nylon mesh to remove wolfberry seeds and insoluble matter;

[0057] In step 5, the wolfberry polysaccharide extract after remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com