Injection molding technique and apparatus for improving production efficiency

A technology of injection molding process and production efficiency, which is applied in the field of injection molding process and devices, can solve the problems of long process time and low production efficiency, and achieve the effect of improving production efficiency and saving time.

Inactive Publication Date: 2008-10-29

李飞宇

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention provides an injection molding process and device for improving production efficiency. Disadvantages of length and low production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

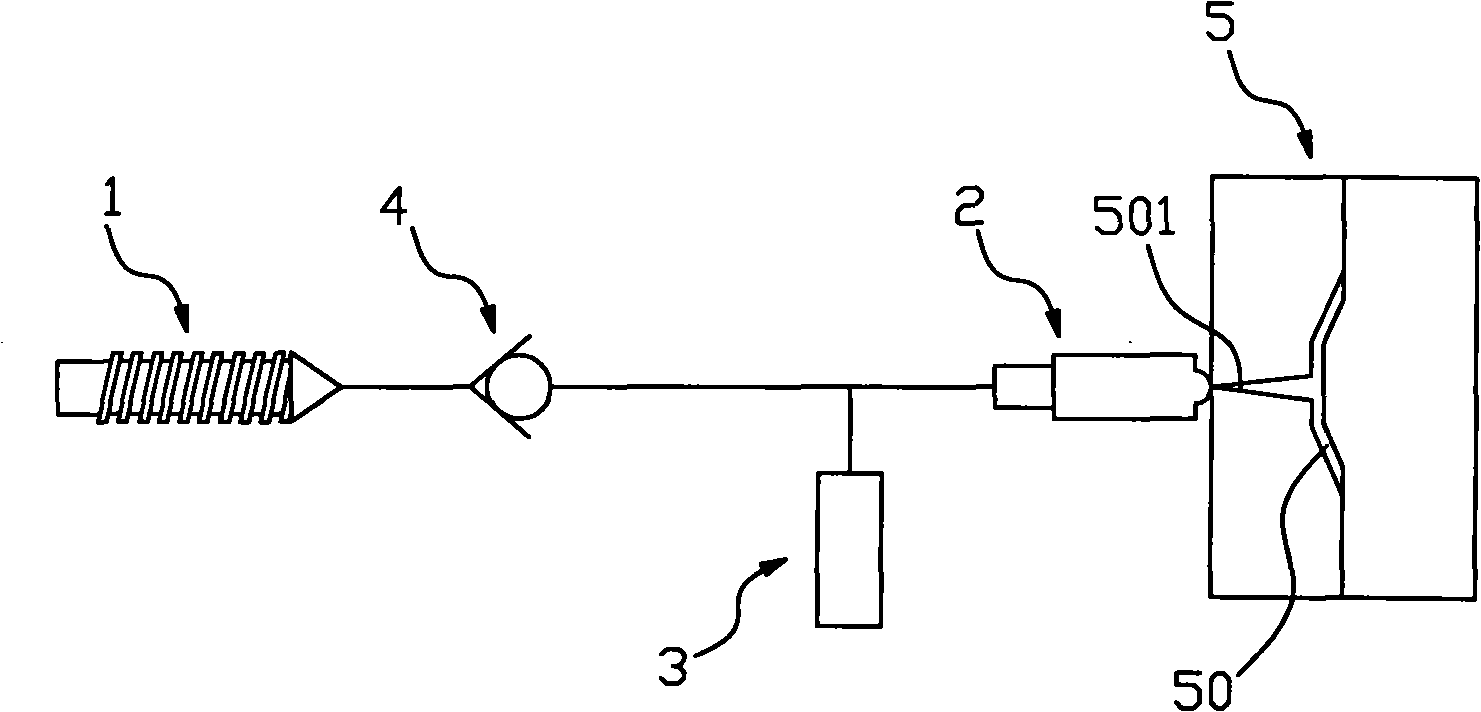

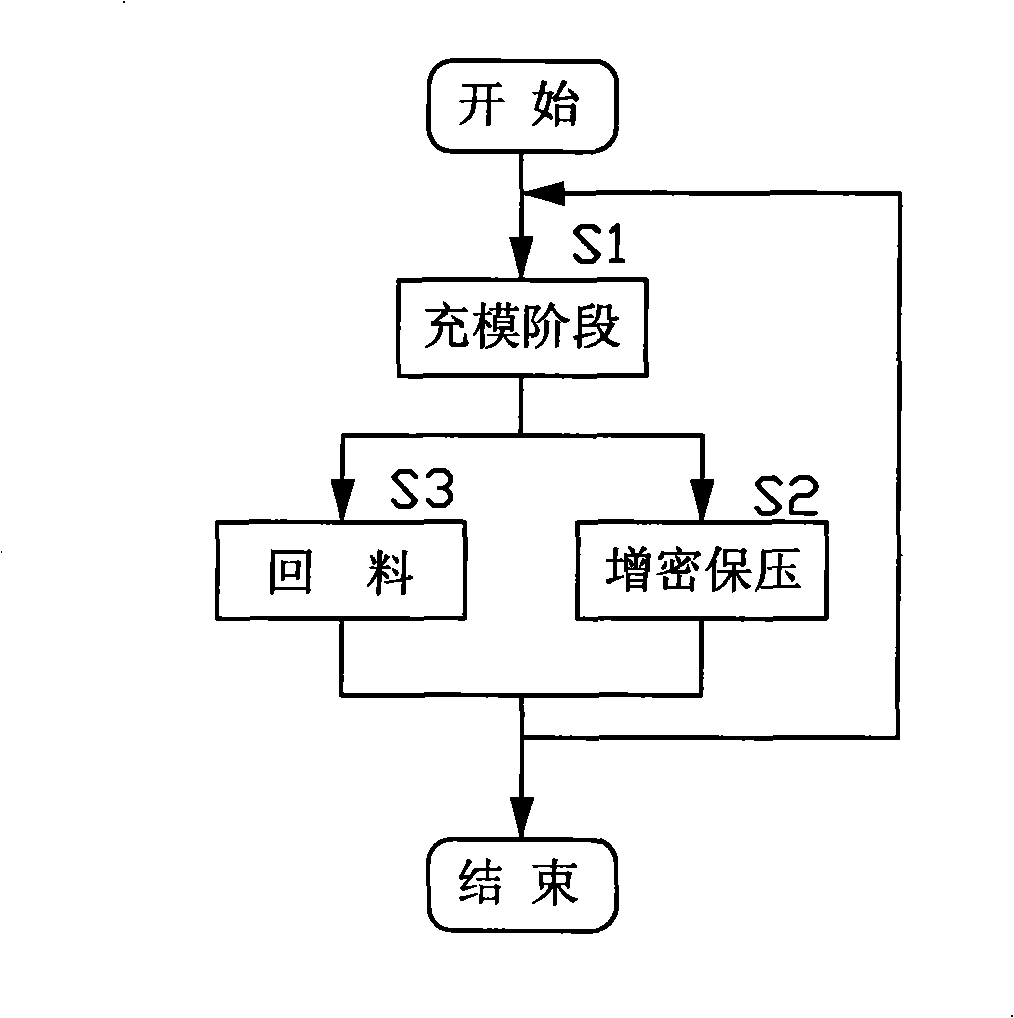

The invention relates to an injection molding technique for improving the manufacture efficiency and a device thereof, which mainly includes that after compounding a die, a screw in the material cylinder of an injection molding machine moves forwards to press a plastic fused mass in the material cylinder into the die cavity of the die to finish the stage of mold filling; a pressure device is used for applying pressure to the plastic fused mass near the location of a nozzle in the material cylinder from the side surface of the material cylinder to finish the stages of increasing density and maintaining pressure; the pressure device stops applying pressure and the screw moves forwards again to circularly carry out next injection. The invention creatively adopts the pressure device independent from a main screw to finish the stages of increasing density and maintaining pressure, thus leading the two stages of increasing density and maintaining pressure to be carried out simultaneously; thereby saving the time consumed by one of the two stages and greatly improving the manufacture efficiency.

Description

An injection molding process and device for improving production efficiency technical field The invention relates to a molding process of plastic parts, in particular to an injection molding process and a device for improving production efficiency. Background technique Usually, the injection molding process includes three stages: mold filling, densification and pressure holding, recycling and cooling. The plastic melt is pressurized by the screw in the barrel, and injected into the cavity of the mold from the nozzle. As the screw advances, the plastic melt gradually fills the entire cavity. This stage is the mold filling stage. When the plastic melt fills the entire cavity, the screw continues to move forward and remains at the final position for a period of time. This process is the stage of densification and pressure holding, and its main purpose is to make the injection molded parts more compact and have a certain strength. Then, the screw rotates while retreating, so ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C45/57B29C45/23B29C45/50

Inventor 王湘冀陈家和

Owner 李飞宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com