Goods train sliding chute wear plate material

A technology for railway wagons and wear plates, which is applied in the field of wear plate materials for railway wagon chute, which can solve problems such as difficult installation, fast wear, and heavy maintenance workload, and achieve the effects of prolonging service life, improving wear resistance, and reducing difficulty

Inactive Publication Date: 2010-10-13

JIANGSU TIEKE NEW MATERIAL CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The wear plate of the traditional railway freight car chute is generally made of metal, and the friction between it and the body of the freight car chute is metal-to-metal. The product wears quickly during use, has a short service life and a large maintenance workload; in addition, the metal material When performing embedded security, it is difficult to install and operate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

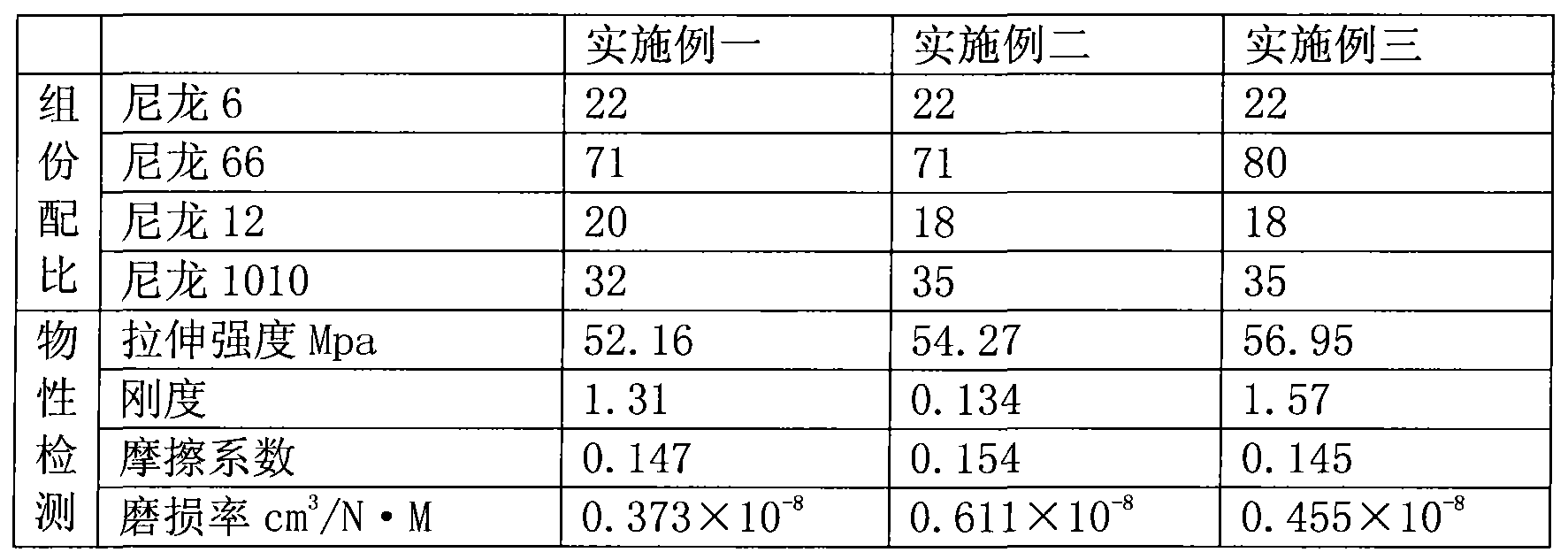

[0010] The following list provides material components and weight proportions of three embodiments of the present invention:

[0011]

[0012] The invention is used in the manufacturing process of the wear plate of the chute, and the product is obtained by extruding and granulating after blending four kinds of nylon materials, and then through one-time injection molding.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the manufacture of polymer wear-resistant materials and relates to the manufacture of a material for the parts of a railway freight car, particularly to a material used for the slide groove wear plate of the railway freight car. The material is the blend of various nylon materials in weight proportions as follows: 20-25 parts of nylon 6, 70-80 parts of nylon 66, 15-20 parts of nylon 12 and 30-40 parts of nylon 1010. The slide groove wear plate made of the material can meet the requirements of strength, rigidity and frictional property for railway freight cars. Compared with the prior metal wear plate, the slide groove wear plate has improved wear resistance, prolonged service life, good elasticity, and less difficulty in embedded installation.

Description

technical field [0001] The invention belongs to the manufacture of polymer wear-resistant materials, and relates to the manufacture of a railway wagon component material, in particular to a railway wagon chute wear plate material. Background technique [0002] The wear plate of the traditional railway freight car chute is generally made of metal, and the friction between it and the body of the freight car chute is metal-to-metal. The product wears quickly during use, has a short service life and a large maintenance workload; in addition, the metal material When performing embedded security, it is not easy to install and difficult to operate. [0003] The technical problem to be solved by the present invention is to provide a railway wagon chute wear plate with low wear rate, strength and rigidity that can meet the use requirements of the wagon chute wear plate. Contents of the invention [0004] The material of the railway freight car chute wear plate of the present inven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L77/06C08L77/02

Inventor 吕珏

Owner JIANGSU TIEKE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com