Hot die steel for die-casting

A technology of hot work die steel and mass percentage, which is applied in the field of hot work die steel for die-casting and aluminum die-casting die materials, which can solve the problems of increased thermal stress in water-cooling holes, cracks, shape restrictions of water-cooling holes, etc., and achieve the suppression of impact value Reducing and inhibiting the coarseness of crystal grains and inhibiting thermal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Next, embodiments of the present invention will be described as follows.

[0088] Hereinafter, the present invention will be described in detail with reference to the steel of the present invention and the comparative steel, but it should be understood that the present invention is not limited to the illustrated content.

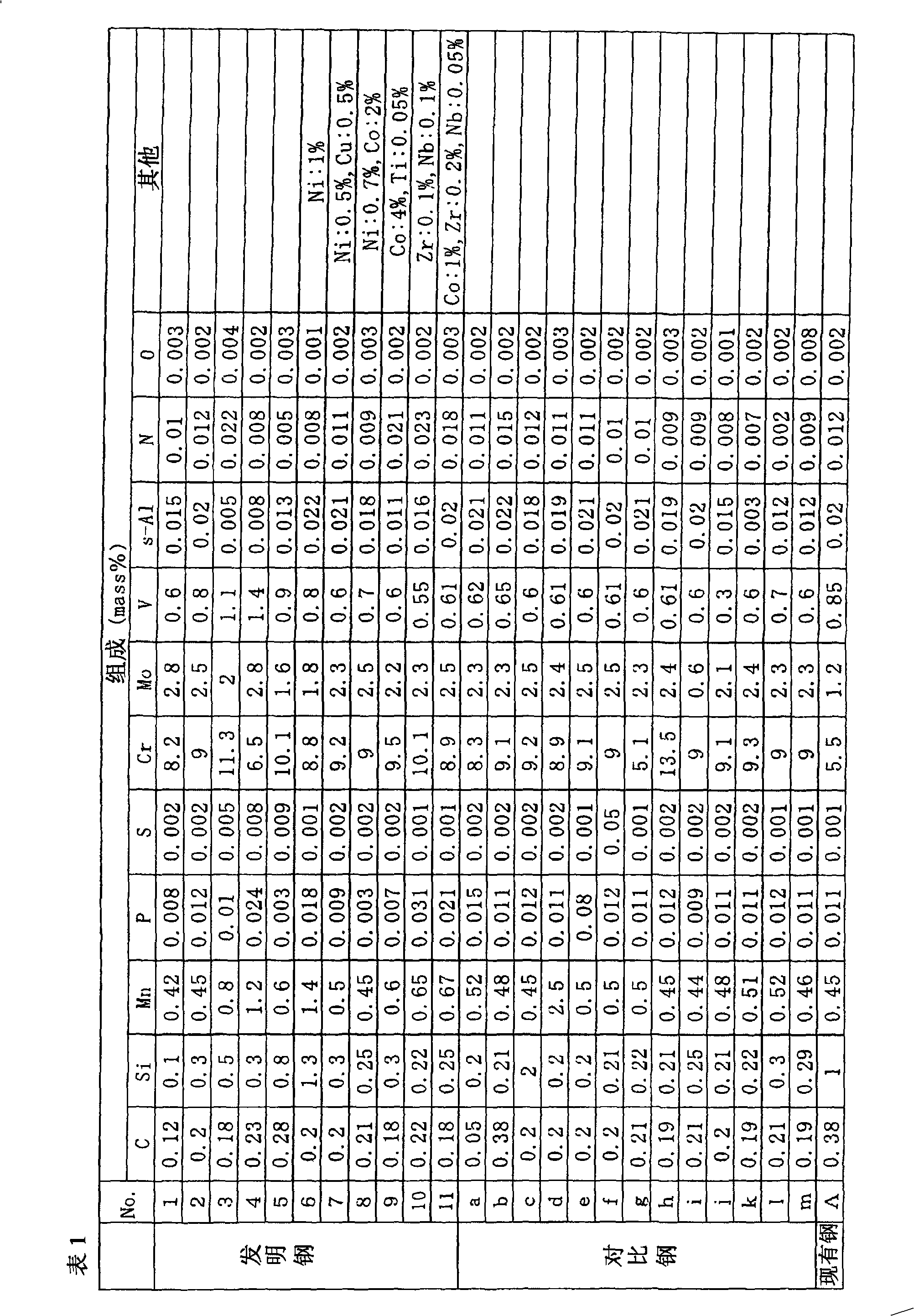

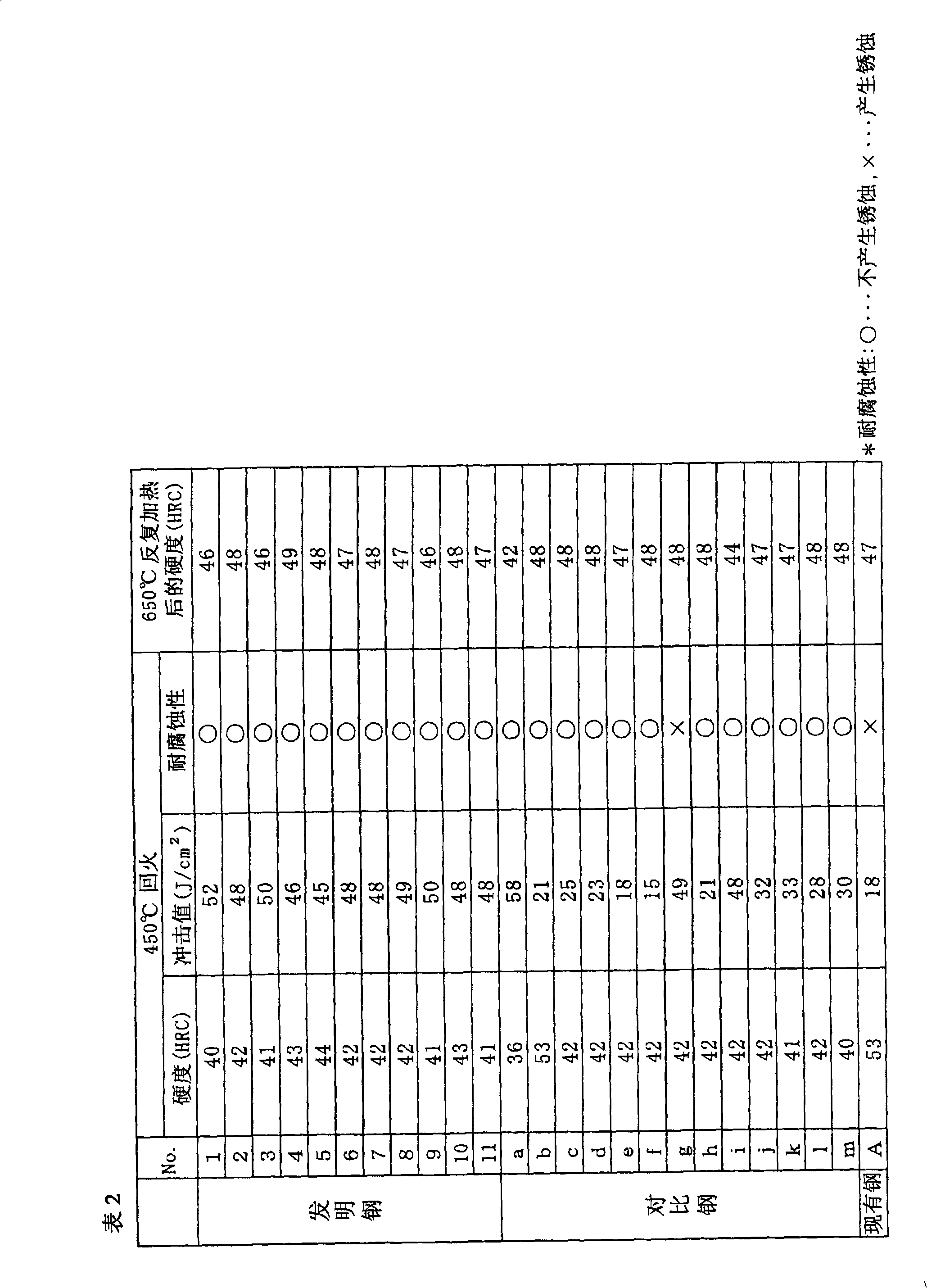

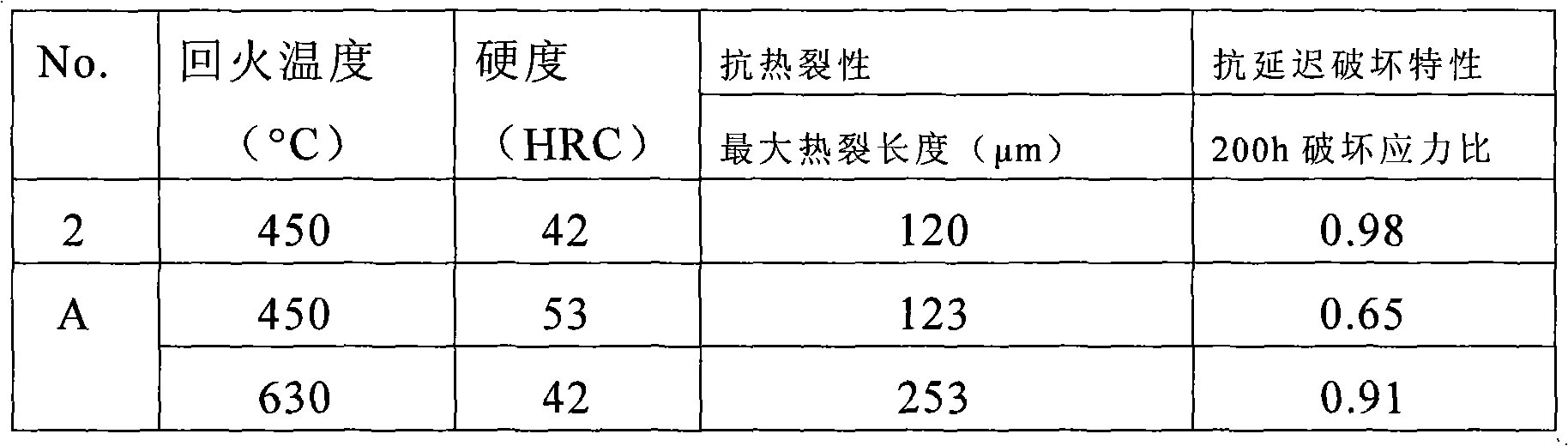

[0089] Steels with various compositions shown in Table 1 were melted in a 150Kg vacuum high-frequency induction furnace, and the obtained steel ingots were forged at 1200° C. into square rods with a cross-section of 60×60 mm.

[0090] After cutting this square bar into a length of 500 mm, it heated to 1030 degreeC, and performed oil quenching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com