Deep foundation pit steel reinforced concrete fender post, producing and embedding method thereof

A technology of reinforced concrete and retaining piles, which is applied in the direction of manufacturing tools, sheet pile walls, and foundation structure engineering. It can solve problems such as unreasonable cross-sections and reinforcements, pollute the environment, and waste materials, so as to facilitate manufacturing and speed up construction. Speed, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

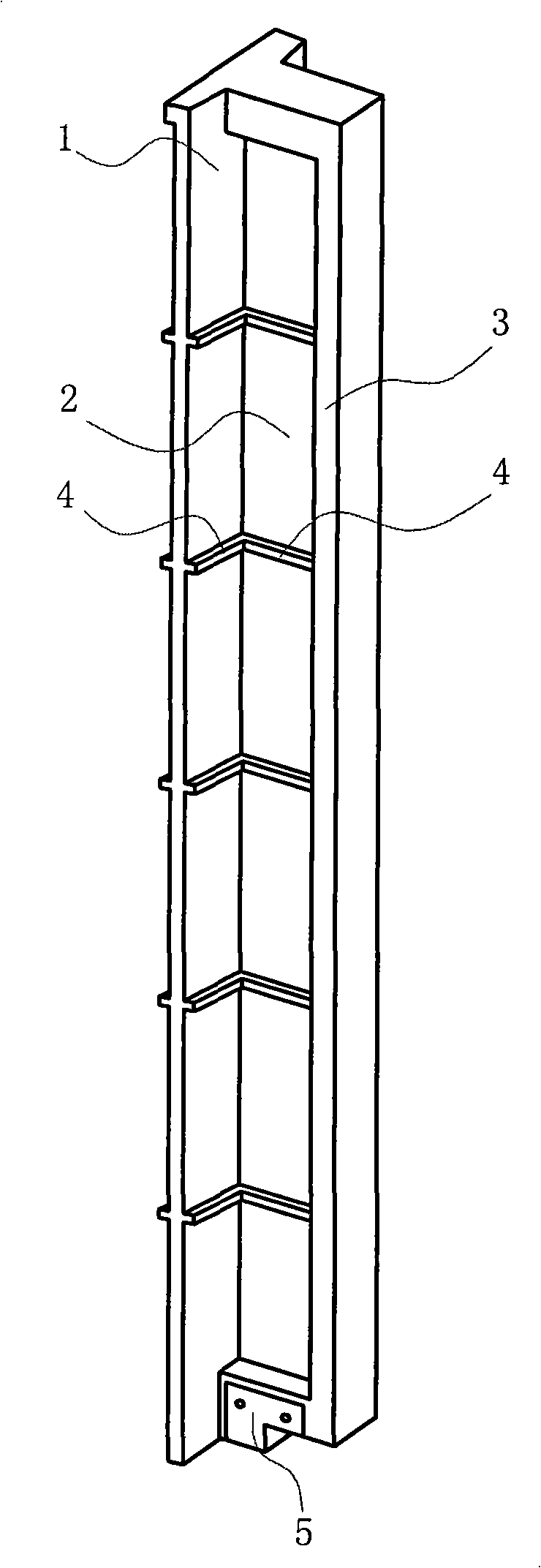

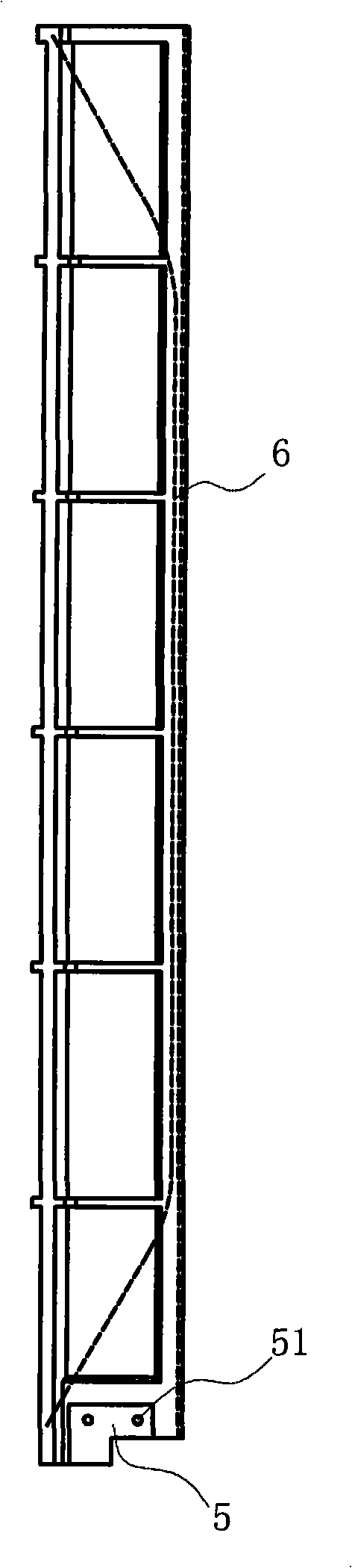

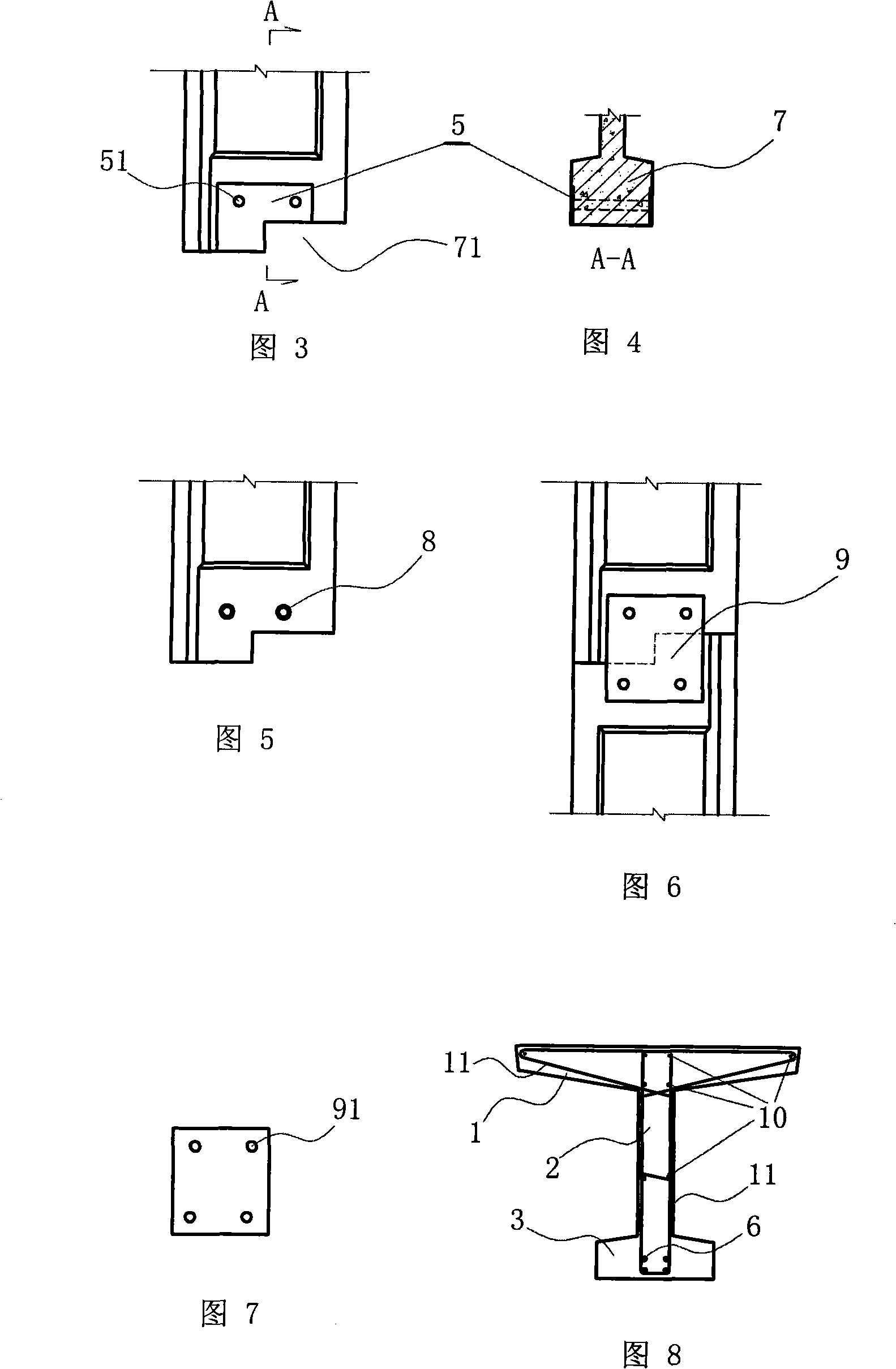

[0040] A reinforced concrete enclosure pile for a deep foundation pit has a web 2, a flange I1 is connected to one side of the web, and a flange II3 with a width smaller than the flange I is connected to the other side of the web, the web and the flange I is vertically provided with steel bars 10, and the web at one end of the pile body has a thickened section 7, and this thickened section is provided with a connecting fixture, which is: embedded in the thickened section parallel to the thickened The length in the thickness direction of the section is equivalent to the steel pipe 8 with the thickness of the thickened section; a non-prestressed steel strand 6 is longitudinally embedded in the other side of the web, and the non-prestressed steel strand is also located in the middle of the flange II3. The two ends of the stranded wire are inwardly bent and extend to the flange I; ribs 4 are provided at intervals on the web and the flange.

Embodiment 2

[0042]A method for manufacturing and embedding reinforced concrete enclosure piles for deep foundation pits, including tying steel reinforcement cages, supporting formwork, pouring concrete, demoulding, raising houses, pressing piles, and transporting piles, and the tying steel reinforcement cages are combined Reinforcement cage, the combined reinforcement cage is made of a thickened section with a gap 71 at one end of the web-shaped cage part, the flange I1-shaped cage part and the web-shaped cage part 7. Combined combined reinforcement cage of the cage part, the notch 71 of the cage part of the thickened section is a notch towards the end face of the cage part of the thickened section and the direction facing away from the flange I1-shaped cage part, said The flange I1-shaped cage part of the combined reinforcement cage is connected to one side of the web 2-shaped cage part, and the web 2-shaped cage part and the flange I1-shaped cage part are provided with corresponding stir...

Embodiment 3

[0044] The manufacturing and embedding method of reinforced concrete retaining piles for deep foundation pits in this example is different from Example 2 in that the integral translational side form described is made of all-steel structure and can be placed on the ground to support formwork or be removed freely. The side form of the mould, the main frame inside the side form is made into a groove-shaped main frame 131, and this groove-shaped main frame doubles as a web 2 convex edge mold so that the web has a convex edge 4, and the gap between the opposite side molds The upper brace is made into a groove-shaped brace 12, and this groove-shaped brace doubles as a flange I1 rib mold so that the flange I has a rib 4; other steps are the same as those of Example 2, and in addition, when the pile is pressed, the Mud or water is injected into the gap between the convex rib and the soil and the pile body to reduce the friction resistance between the pile body and the soil layer when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com