Magic block combined lining board for PVC vacuum compression

A technology of vacuum molding and magic blocks, which is applied in the field of auxiliary devices and can solve the problems of high requirements for molding substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

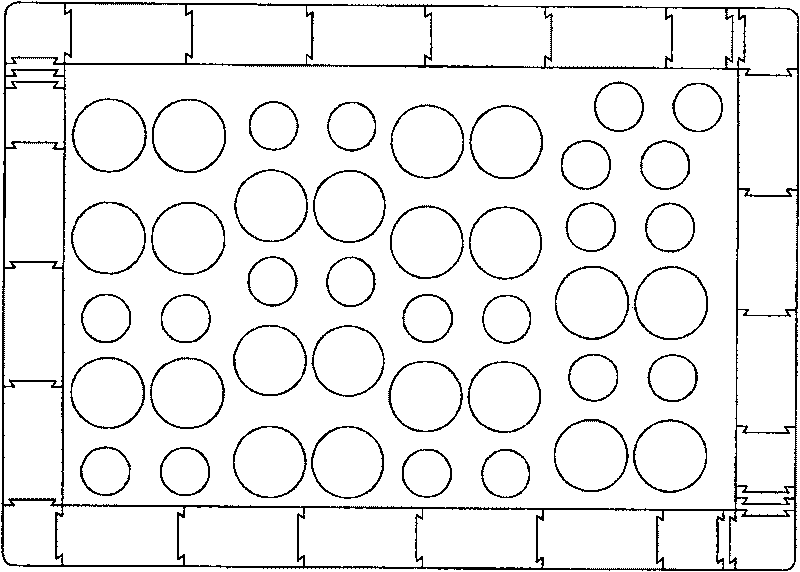

[0014] PVC vacuum molded magic block combination liner, see Figure 1a , 1b : Including interlocking blocks and cushion blocks similar to the thickness of the molded sheet, characterized in that there are two types of interlocking blocks: one is a rectangular block used as a frame, which has two parallel upper and lower surfaces, and is perpendicular to the upper and lower surfaces. Two parallel side planes; the other is a square block used as a corner, which has two parallel upper and lower surfaces, and two adjacent side planes perpendicular to the upper and lower surfaces; Among the vertical sides of the surface, one side has a protruding dovetail wedge, and the other side has a recessed dovetail groove; the frame is composed of several specifications of plug-in blocks, and the middle is filled with cylindrical spacers of the same thickness.

[0015] Rectangular patchwork used as a frame has two parallel sides that are planes perpendicular to the upper and lower surfaces, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com