Electrobath structure

An electrolytic cell and cell body technology, applied in the field of electrolytic cell structure, can solve problems such as high economic cost and complex structure, and achieve the effects of safe and simple operation, reduced transportation cost, and convenient modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

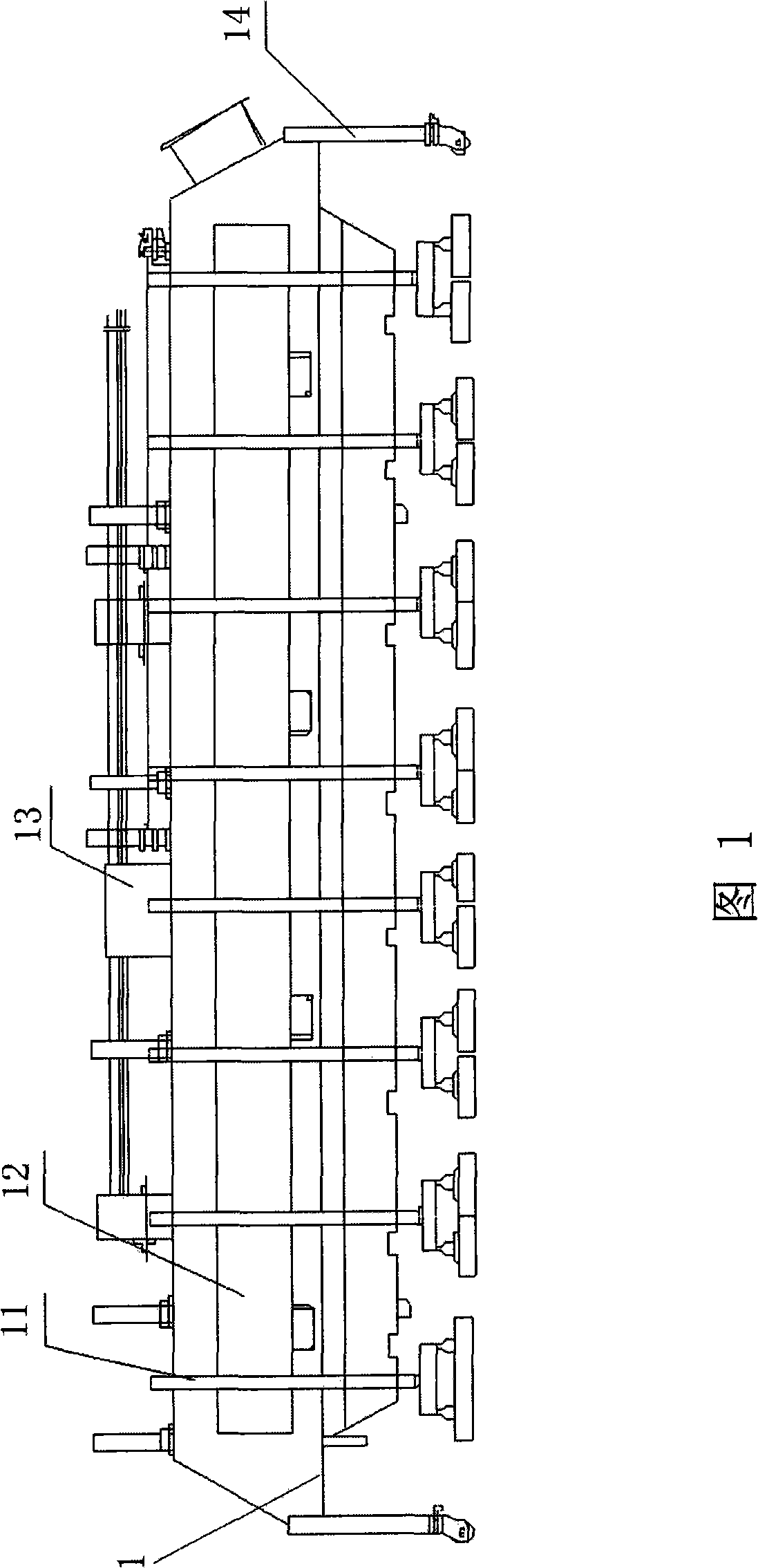

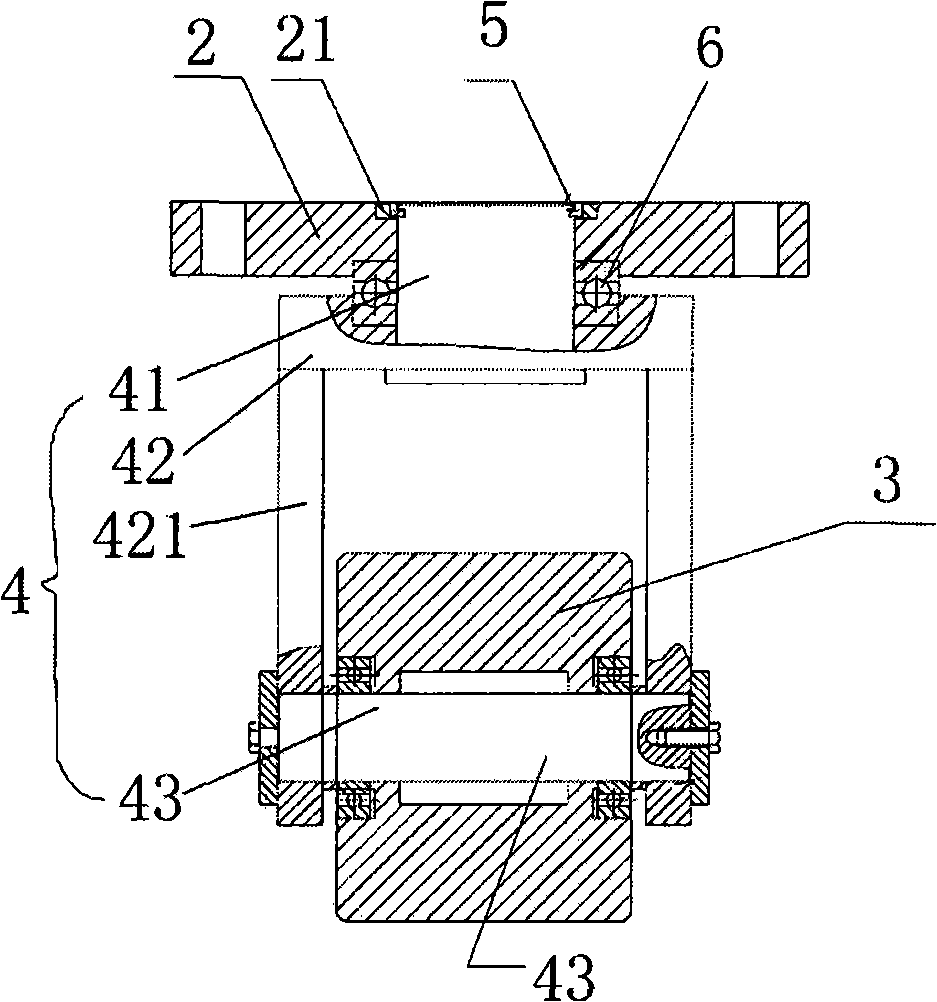

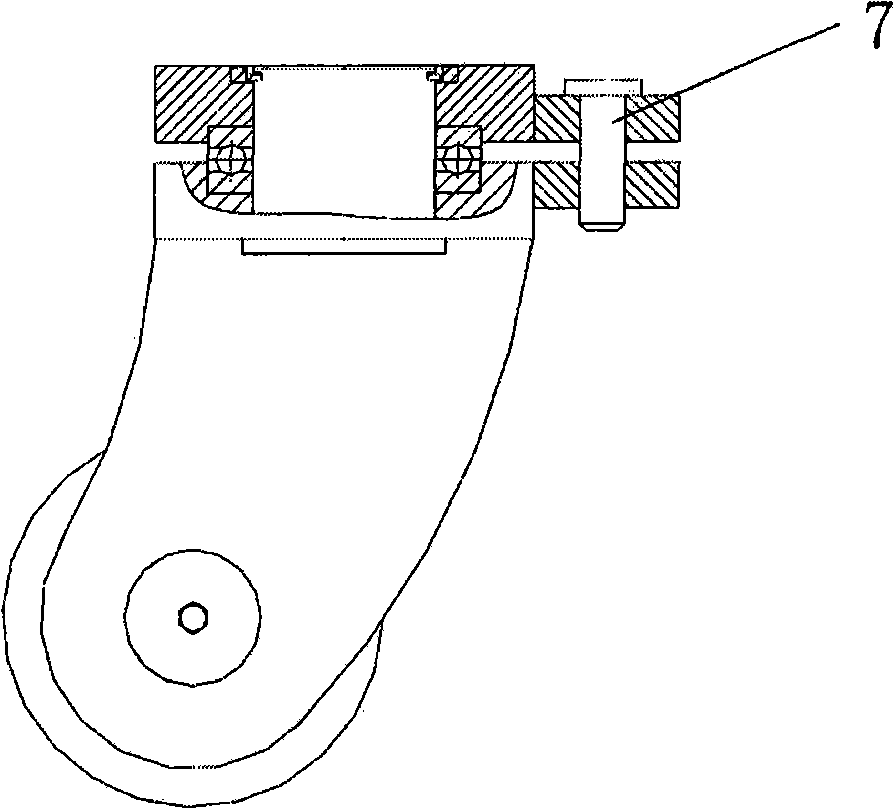

[0024] See Figure 1 to image 3 , an electrolytic cell structure of the present invention, comprising a cell body and an upper part 1 of the electrolytic cell, the upper part 1 of the electrolytic cell includes an anode rod 11, a bus bar 12, a feeding mechanism 13 and four supporting feet 14, each supporting foot 14 is respectively fixed below A support plate 2 is provided, and a rotating wheel 3 is fixed on the support plate 2 through a bracket mechanism 4 .

[0025] In actual use, the support plate 2 is made of a 60mm thick steel plate, which is fixed with the support feet 14 by screws. The rotating wheel 3 is sleeved on the support shaft 43 and fixed between the two side plates 421 of the support body 42 .

[0026] The support shaft 41 connects the support body 42 and the support plate 2, and passes through the support plate 2, and is sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com