High leakage reactance type level adjustable series iron-core reactor

An iron-core reactor and high leakage reactance technology, which is applied in the direction of inductors with magnetic cores, transformers/inductor coils/windings/connections, etc., can solve problems such as changing series reactors and affecting the normal operation of power equipment, and achieve reduction The effect of economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

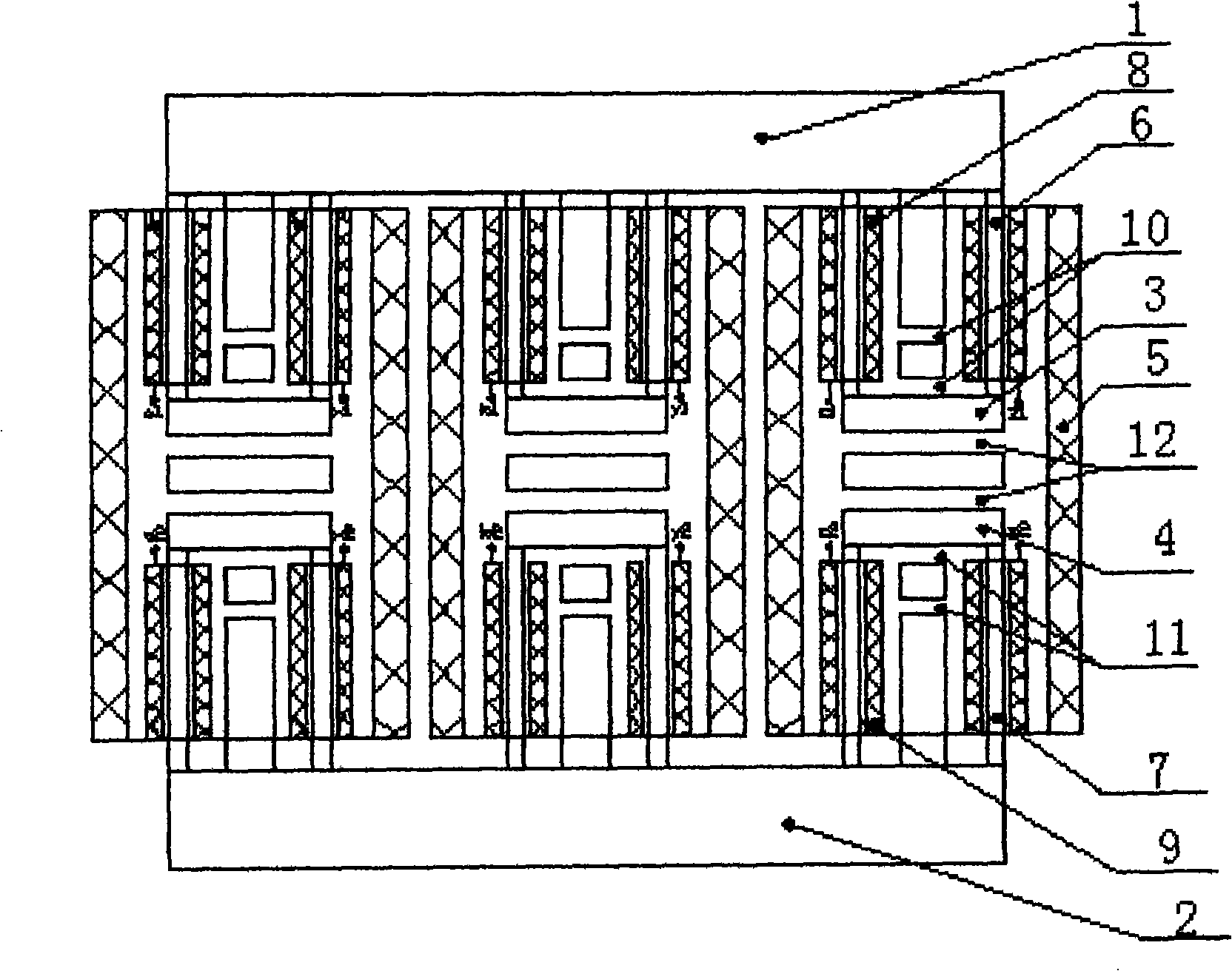

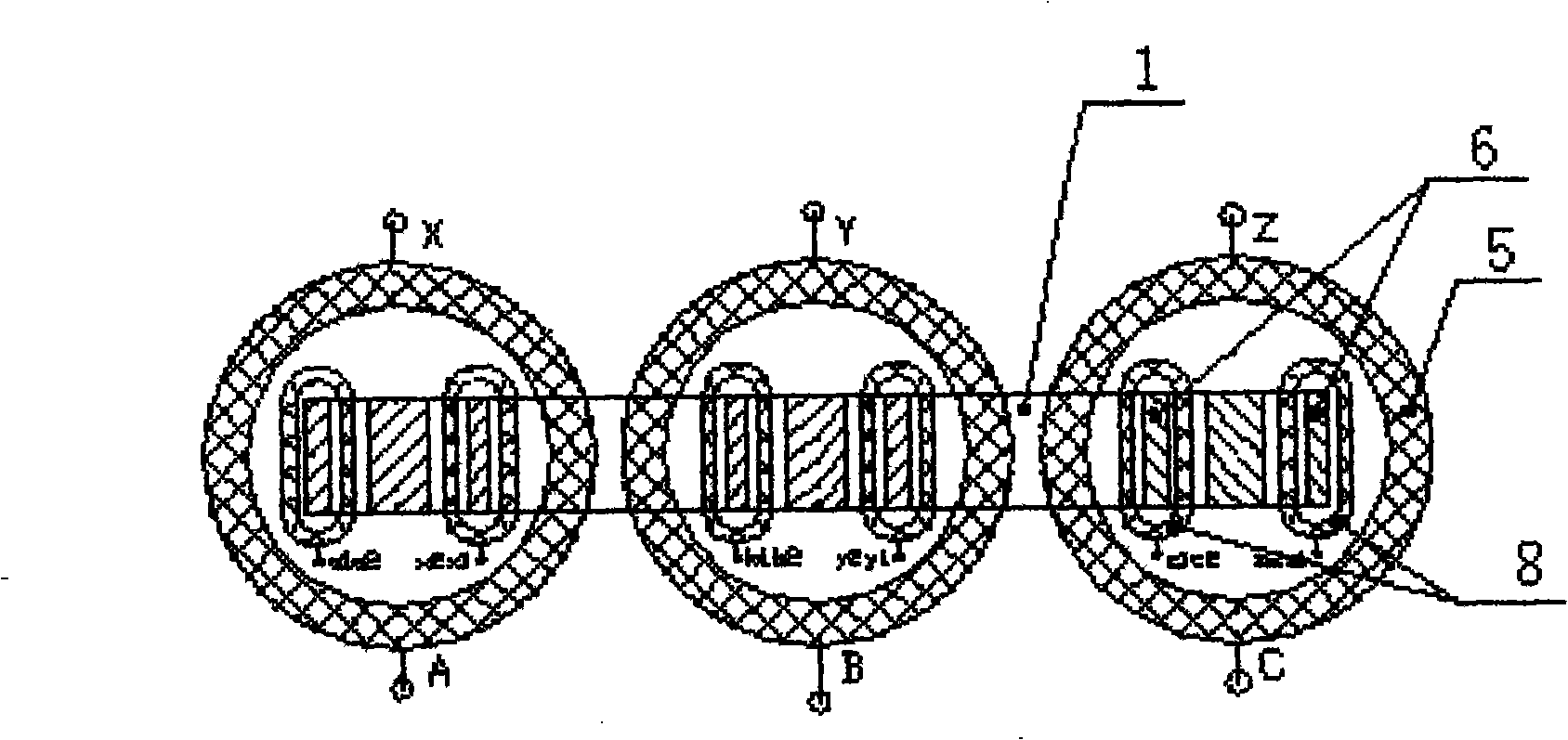

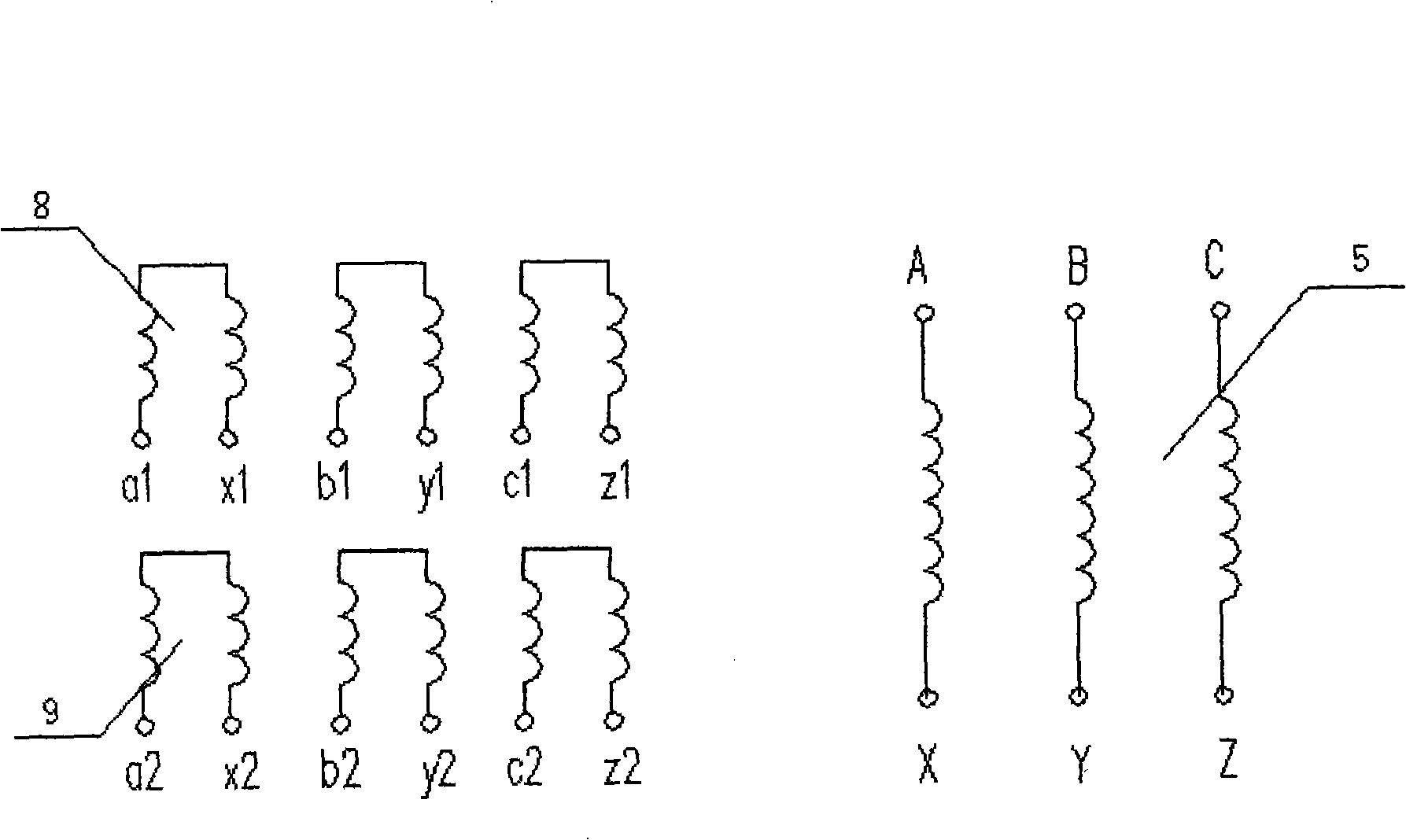

[0013] The structure of the high leakage reactance step-adjustable series core reactor is as follows: figure 1 and figure 2 As shown, the reactor is composed of upper and lower yoke cores, bypass cores, main cores, main winding coils, control winding coils, and air gap sections. The main winding coil 5 is set on the upper main core 3 of the upper yoke core 1 and the lower main core 4 of the lower yoke core 2. The wiring method of the main winding coil is the same as that of a conventional reactor. The wiring principle is as follows: image 3 As shown, an upper control air gap 10 is provided at the bottom of the upper main iron core 3, a lower control air gap 11 is provided at the upper part of the lower main iron core 4, and a common air gap 12 is provided between the upper and lower control air gaps. The upper bypass core 6 and the lower bypass core 7 are arranged on both sides of the main core 3 and the lower main core 4, the upper control winding coil 8 is set on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com