Coiling method for mutual inductor and products produced thereby

A winding method and transformer technology, applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve the problem that the accuracy of the closed winding method transformer cannot meet the requirements, etc. To achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

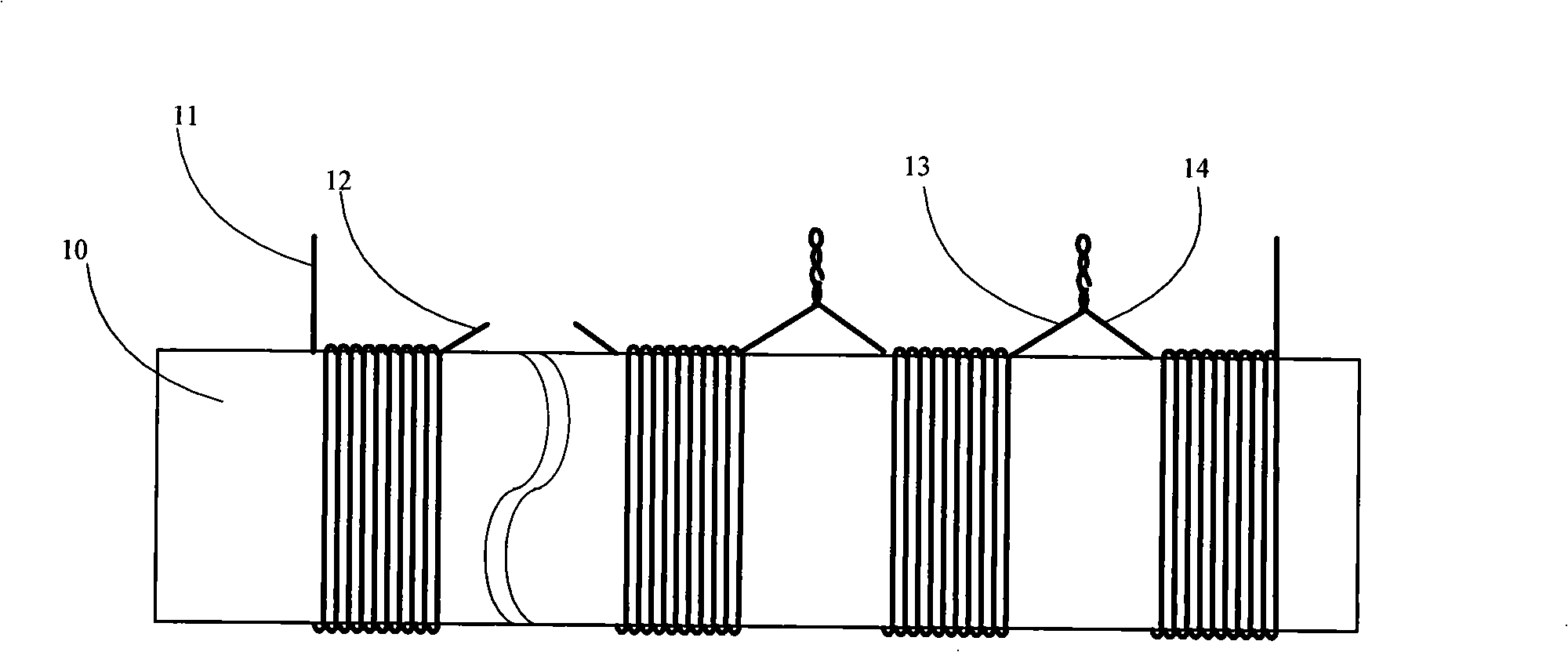

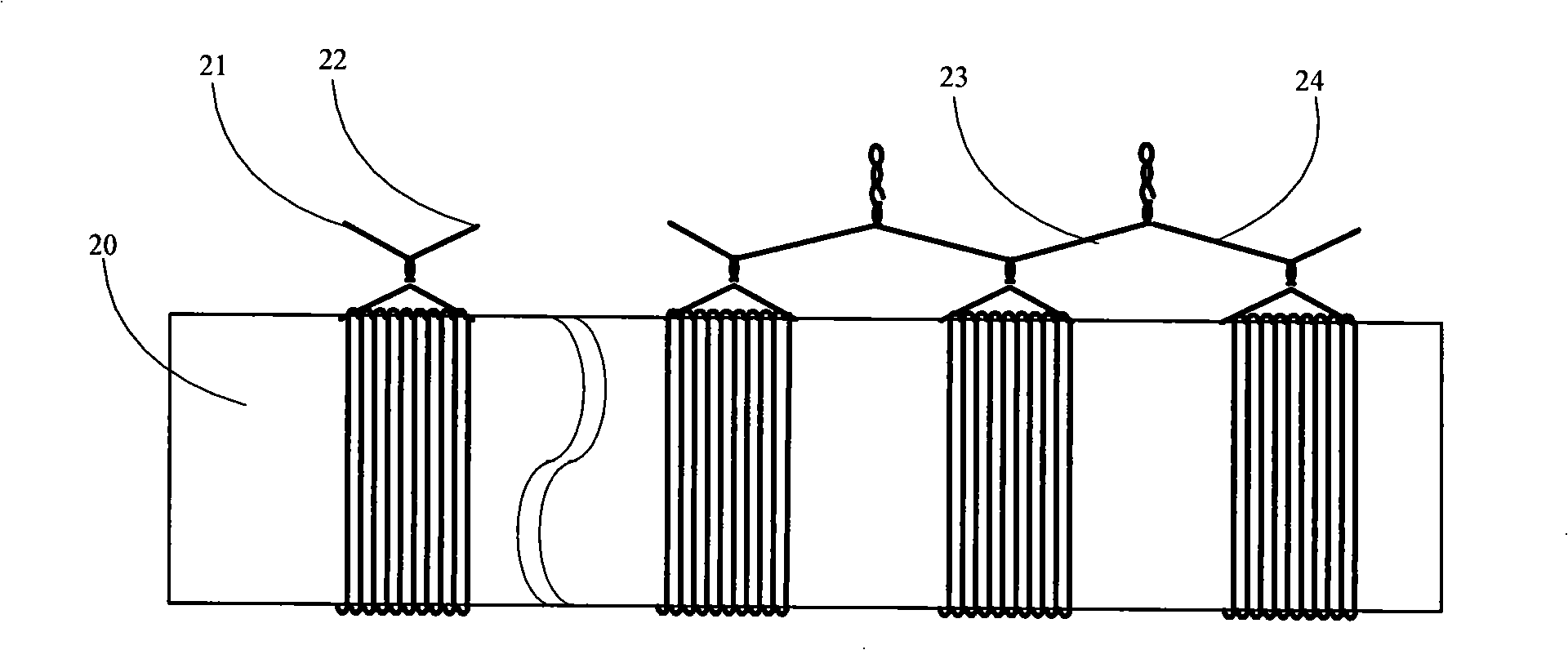

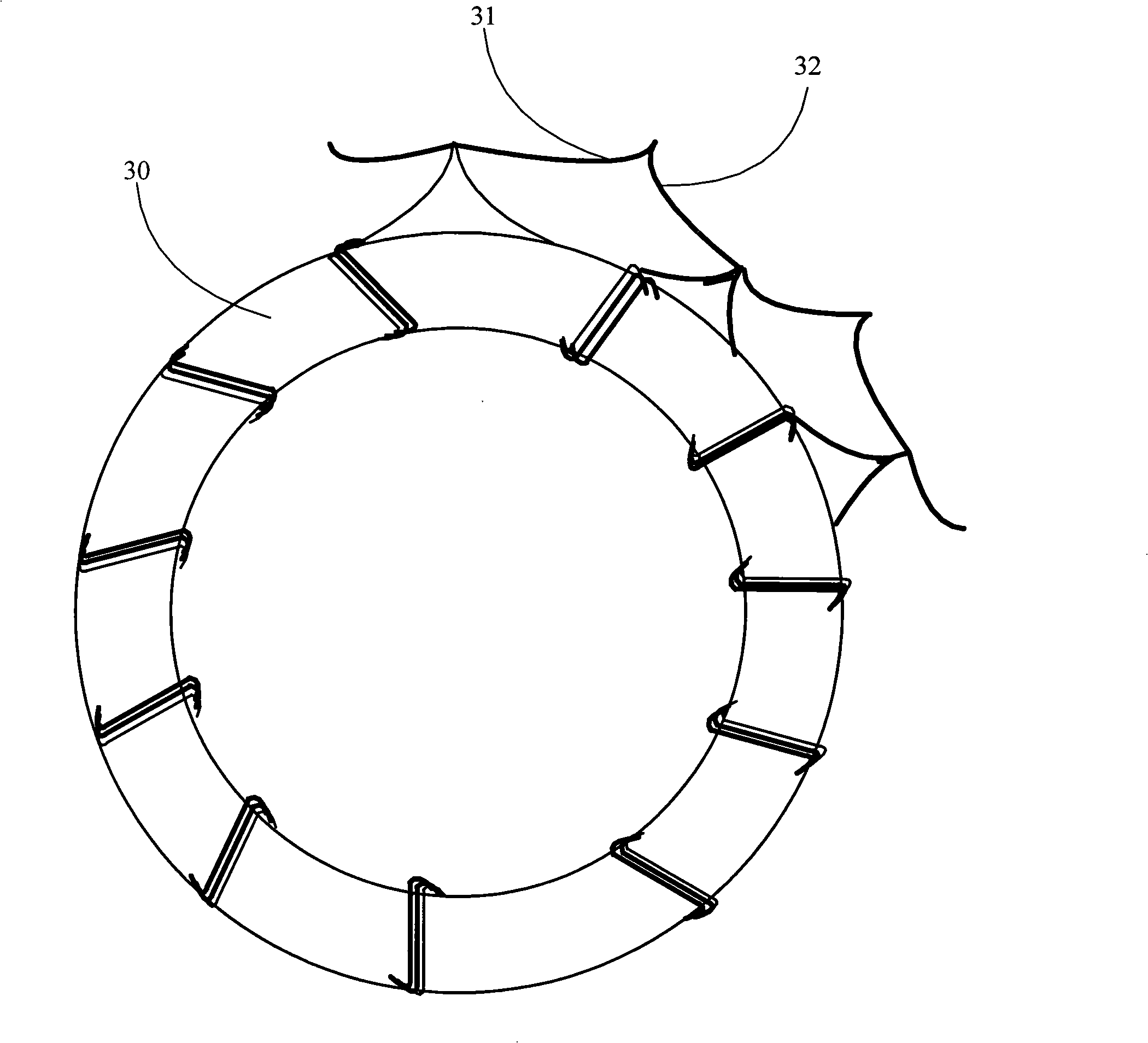

[0025] image 3 Shown is a transformer manufactured by the method of the present invention, and the magnetic core 30 is a ring-shaped magnetic core. Figure 4 for image 3 A partial view of , for illustration purposes, Figure 4 The middle is the flat state of the magnetic core 30, which is about to image 3 The side view of the toroidal core 30 in is cut from a certain part and straightened.

[0026] Such as image 3 As shown, select several (at least two) winding wires of equal length (for example, enameled wires can be selected), each winding wire is helically wound on the annular magnetic core 30, and each winding wire The helixes formed after winding (hereinafter referred to as segments) are evenly distributed in the entire annular magnetic core with equal pitches. The two ends of each winding wire form the head end and the tail e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com