Deicing robot for transmission distribution line

A technology of power transmission and transformation lines and robots, which is applied to the installation of manipulators, electrical components, and cables, etc., and can solve problems such as high consumption, difficult operation, and no deicing machinery for power transmission and transformation lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

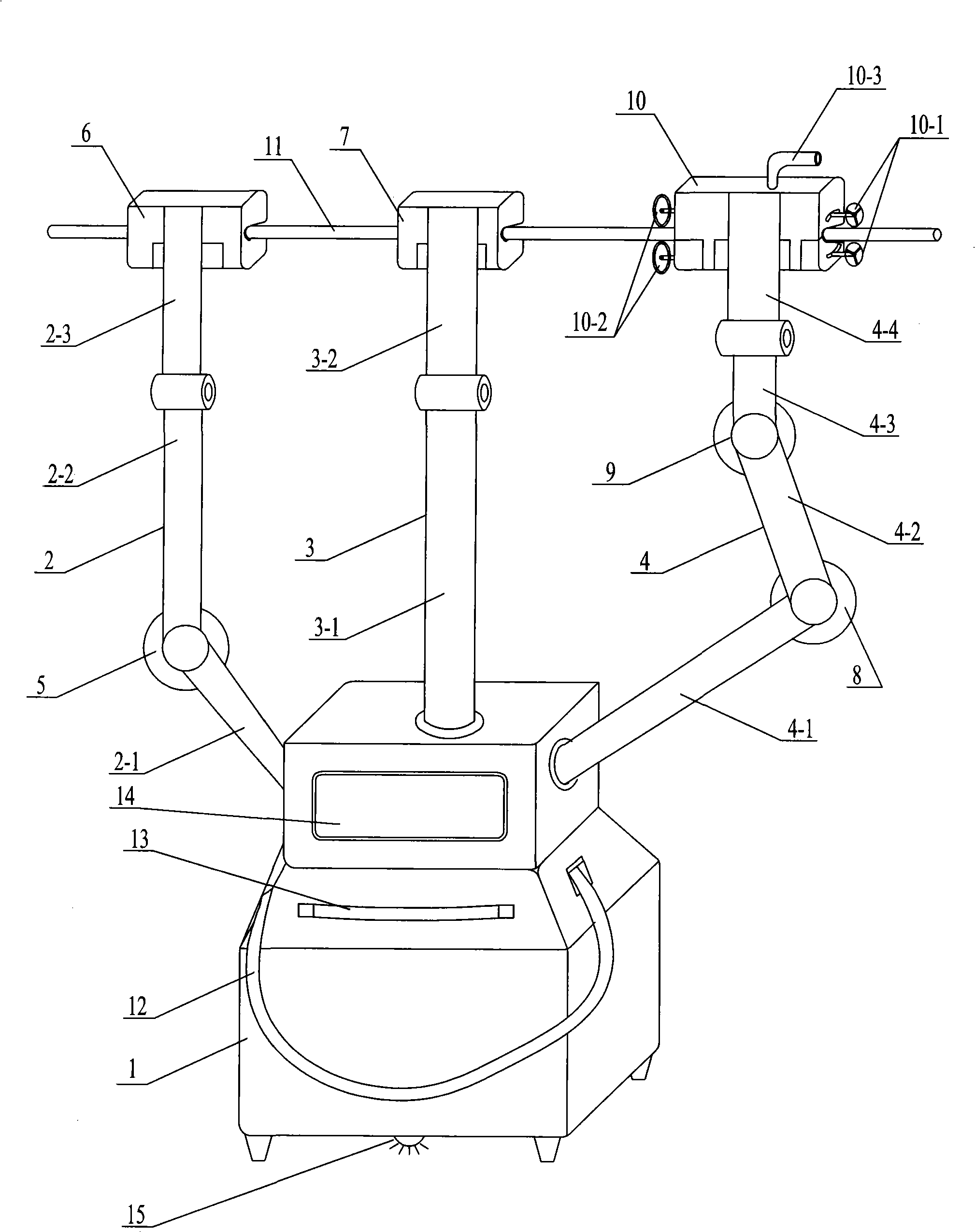

[0023] The host 1 is equipped with a microcomputer control system and a power system, and the host 1 is connected with a flexible push arm 2 , a suspension guide arm 3 and a deicing working arm 4 .

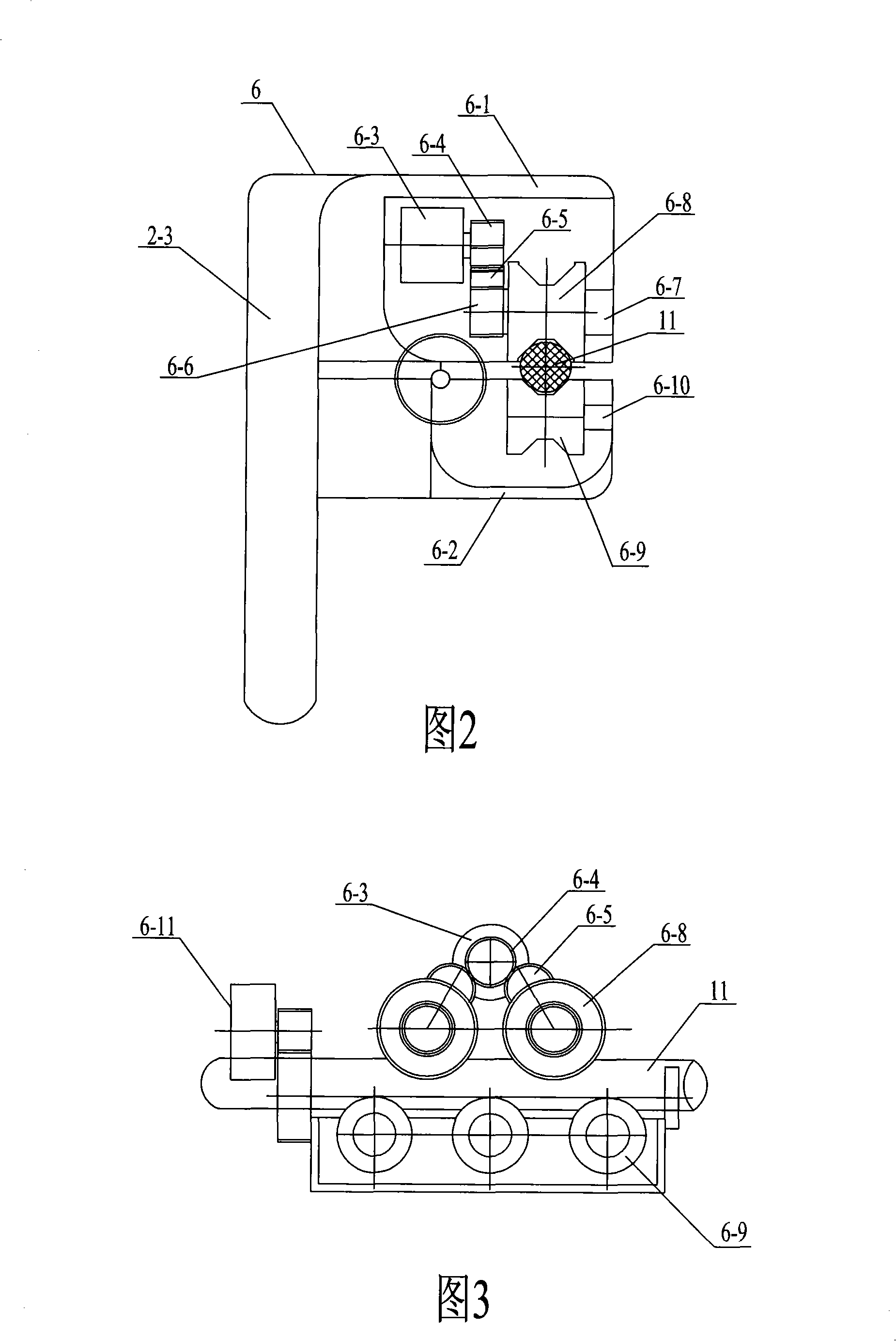

[0024] The flexible pushing arm 2 includes a first flexible pushing arm 2-1, a second flexible pushing arm 2-2 and a third flexible pushing arm 2-3. One end of the first flexible push arm 2-1 is fixedly connected on the main frame 1, and the other end and an end of the second flexible push arm 2-2 are mutually connected by a universal joint 5, and the second flexible push arm 2-2 The other end is hingedly connected to one end of the third flexible pushing arm 2-3, and the other end of the third flexible pushing arm 2-3 is connected to an openable and closing motor power pack 6.

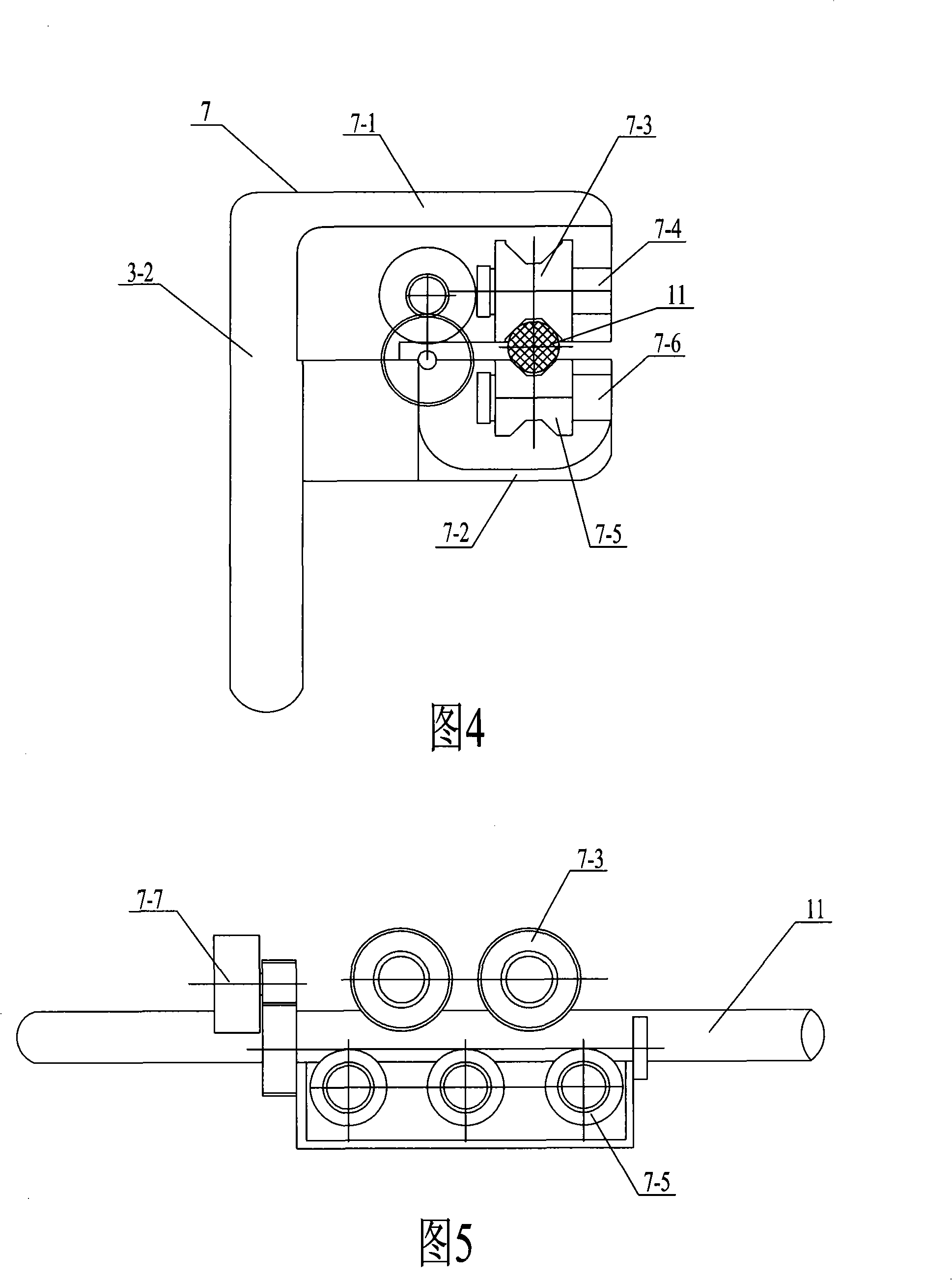

[0025] The suspension guide arm 3 includes a first suspension guide arm 3-1 and a second suspension guide arm 3-2. One end of the first suspension guide arm 3-1 is fixedly connected to the host machine 1...

Embodiment 2

[0036] Such as Image 6 As shown, the power transmission line deicing robot includes a host 16, and the host 16 is equipped with a microcomputer control system and a power system. One end of the suspension guide push arm 17 is fixedly connected to the main machine 16, and the other end is connected to a work head 18 which can be opened and closed. A positive deicing rotary knife set 19 is connected to the front end of the openable and closable working head 18 , and a winding hole 19 - 1 is arranged in the center of the forward deicing rotary knife set 19 .

[0037] The internal structure of the openable working head 18 is the same as that of the openable motor power pack 6 in embodiment 1, and parts such as straps, a pair of insulating handles, microcomputer control system panels, and indicator lights are also set on the main frame 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com