Non-coupled electric stepless gear motor body topological structure

A technology of continuously variable transmission and topology structure, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as limiting the application and development of electric continuously variable transmission, increasing harmonic loss and stray loss, and decreasing the efficiency of electrical transmission. , to achieve the effect of simple structure, simple control and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

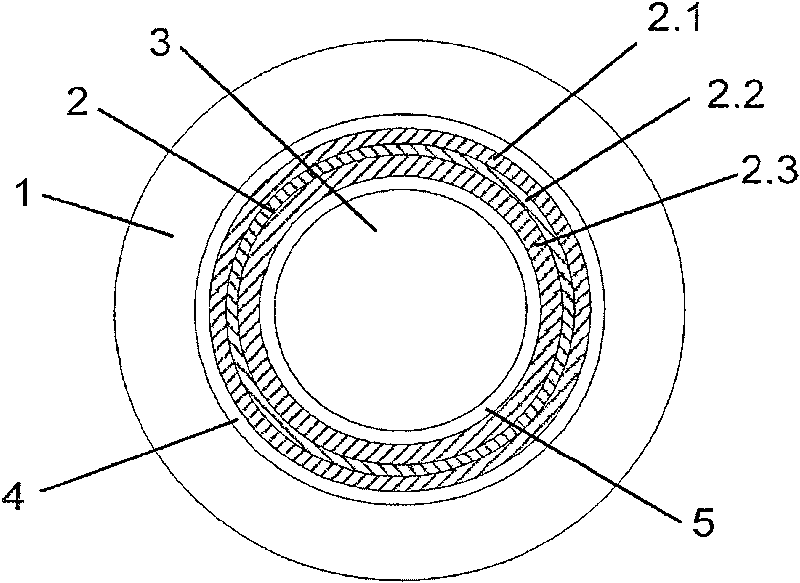

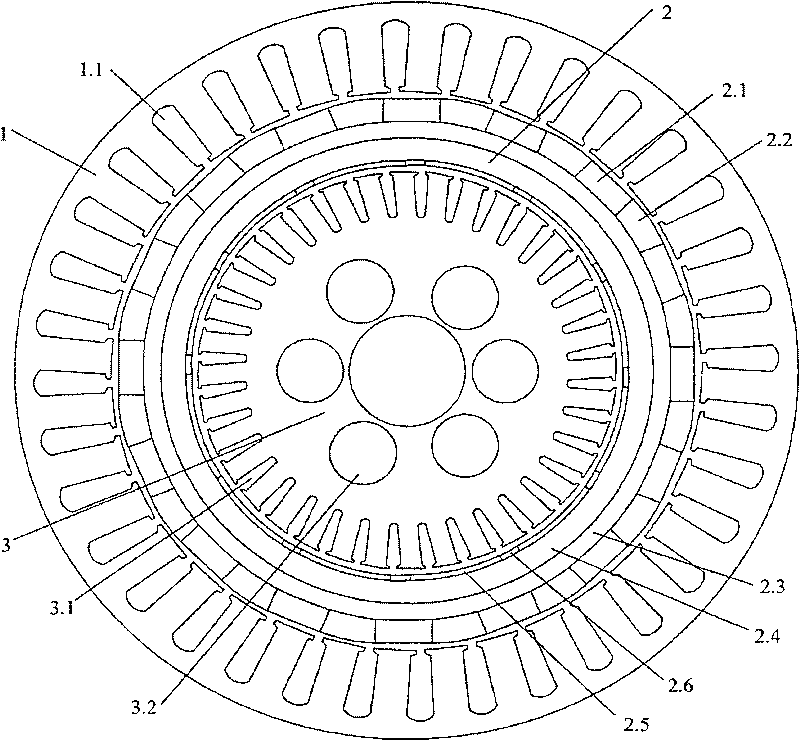

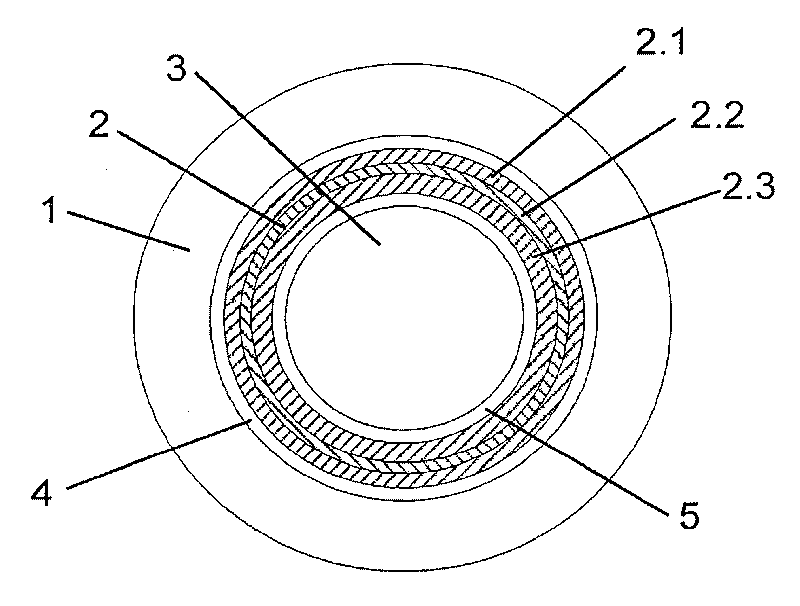

[0015] The non-coupling electric continuously variable transmission of the present invention can be divided into topological structure, including outer layer part, middle part and inner layer part; from the perspective of motor, it can be divided into stator, outer rotor and inner rotor, which can be determined according to different application occasions. The rotor can be arbitrarily selected among the three parts.

[0016] The outer part and the inner part can be placed with permanent magnets, squirrel cage windings, wound windings or salient pole structures. Three-phase or multi-phase distributed windings or concentrated windings can be used. The slots can be straight slots or inclined slots. .

[0017] The middle part consists of three layers. The inner and outer layers can be placed with permanent magnets, squirrel cage windings, wound windings or salient pole structures. The middle layer is a non-magnetic layer, which can be made of aluminum or other non-magnetic materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com