Magnetic isolation outer rotor structure of a stator permanent magnet double rotor motor

A dual-rotor motor and permanent magnet technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, electrical components, etc., can solve the problems of difficult heat dissipation, large loss, and difficult fixation, and achieve the elimination of magnetic field coupling , the effect of reducing rotor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

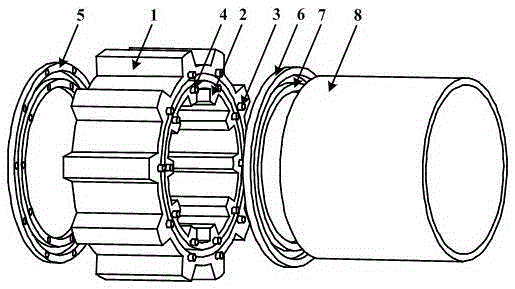

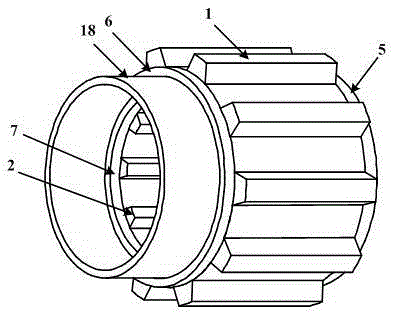

[0011] Such as figure 1 and figure 2 As shown, the present invention proposes that the magnetically isolated outer rotor structure of the stator permanent magnet double-rotor motor includes an outer body 1, an inner body 2, an outer metal strip 3, an inner metal strip 4, a fixed end ring 5, an output end outer end ring 6, The inner end ring 7 and the magnetic spacer 8 at the output end. The innermost side is a cylindrical inner body 2, the inner body 2 is covered with a ring-shaped magnetic partition 8, and the magnetic partition 8 is covered with a cylindrical outer body 1, the outer body 1 is on the outermost side, the outer body 1, the inner body 2 and the magnetic Arranged coaxially every 8.

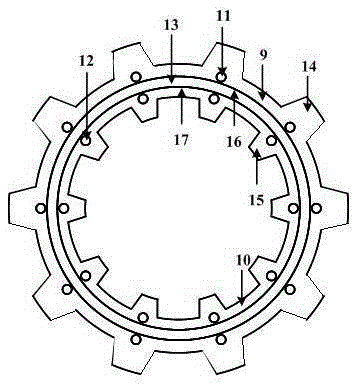

[0012] Such as figure 2 As shown, the outer body 1 and the inner body 2 adopt a lamination structure, the outer body 1 is formed by laminating the outer laminations 9, the inner body 2 is formed by laminating the inner laminations 10, and the outer ring of the outer body 1 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com