Double-side filter water treatment filter material device

A technology of water treatment and filter material, which is applied in the field of water treatment filter material device and double-sided filtration water treatment filter material device, which can solve the problems of increased manufacturing cost, complex equipment structure, and increased volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

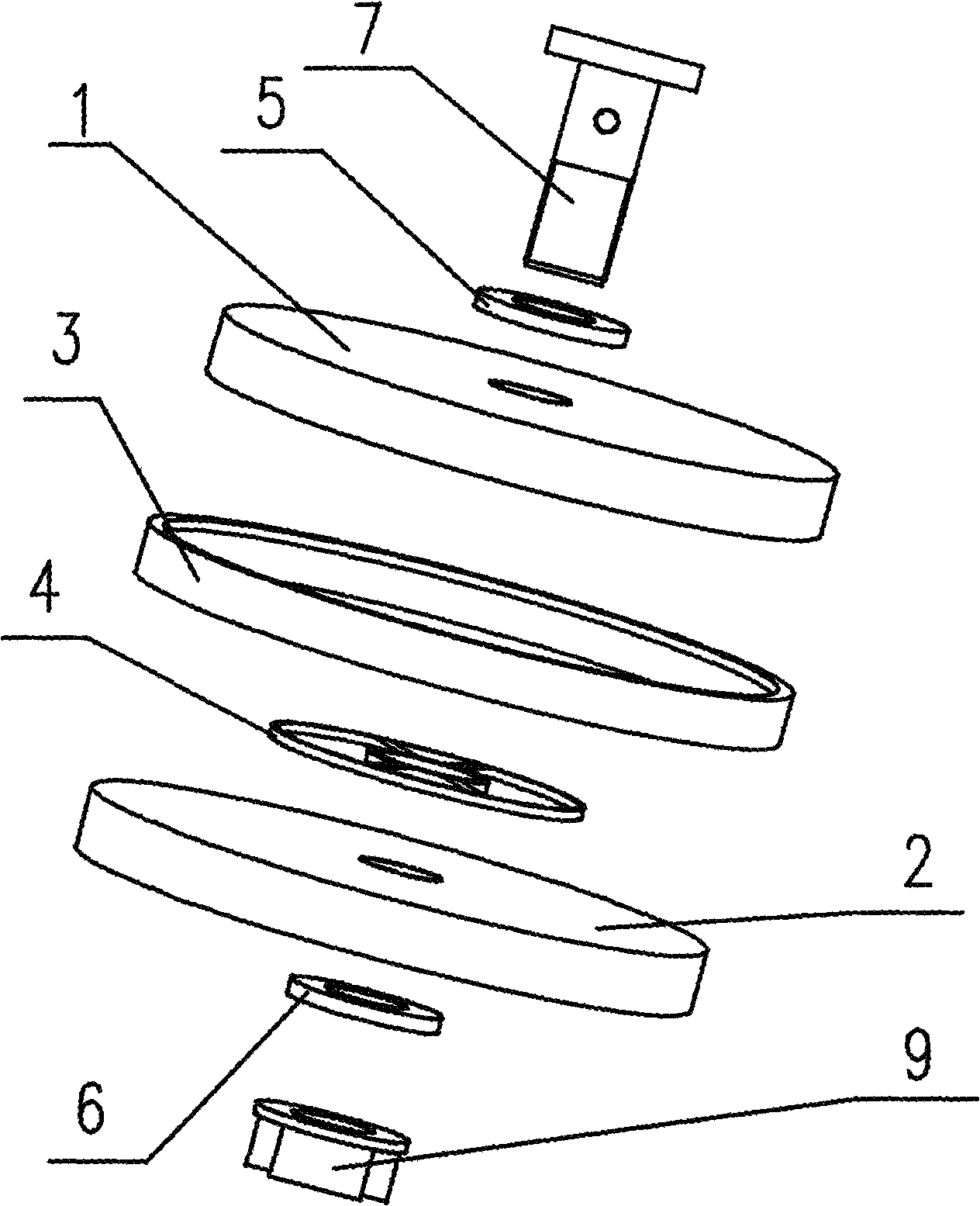

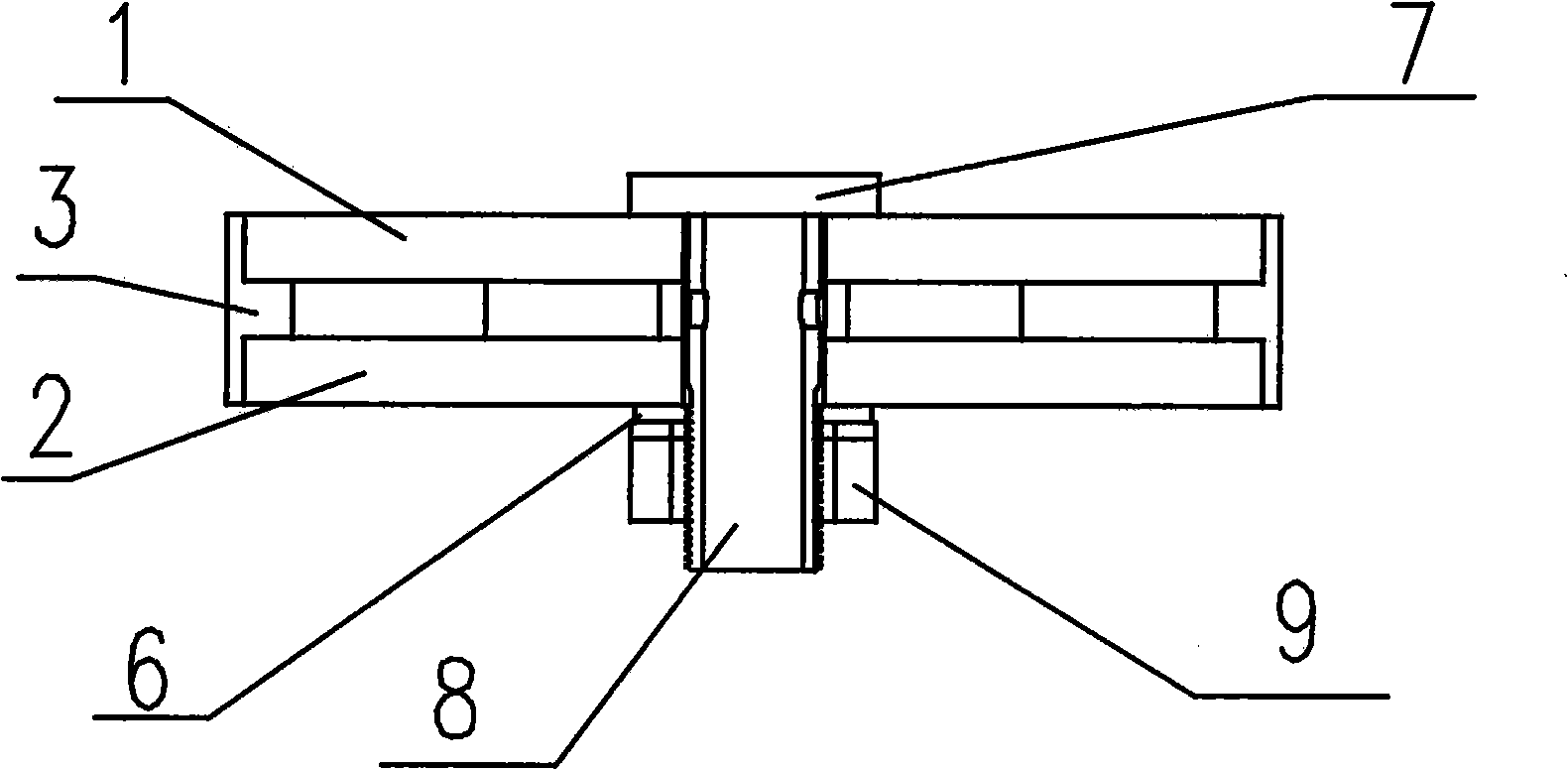

[0009] combine figure 1 , figure 2 Shown:

[0010] Place the filter element 1 on one side of the sealing connector 3 and glue it evenly with glue, put the bolt sealing ring 5 on the top of the bolt 7, pass through the middle hole of the filter element 1 that has bonded the connector, and put the support member 4 on the bolt and fixed on the inside of the filter material 1. Put another piece of filter element 2 through the bolt 7 on the other side of the sealing connector 3, and evenly bond it with glue, put another bolt sealing ring 6 on the lower end of the bolt 7 and close to the outside of the filter element 2, and lock it with a lock nut 9 Tight, forming a sealed cavity with an open lower end. Such as figure 2 Shown: When working, water enters the above-mentioned cavity from both sides of the filter element 1 and 2, passes through the channel of the support member 4, passes through the perforation 8, and finally flows out from the open end 9 of the lower part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com