Balance hinge

A hinge and balance technology, applied in the field of refrigerator door balance hinges, can solve the problems of inability to accurately find the controlled point or angle range, the opening angle is small, the door body falls and closes, etc., to achieve simple structure, slow movement speed, and operation reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

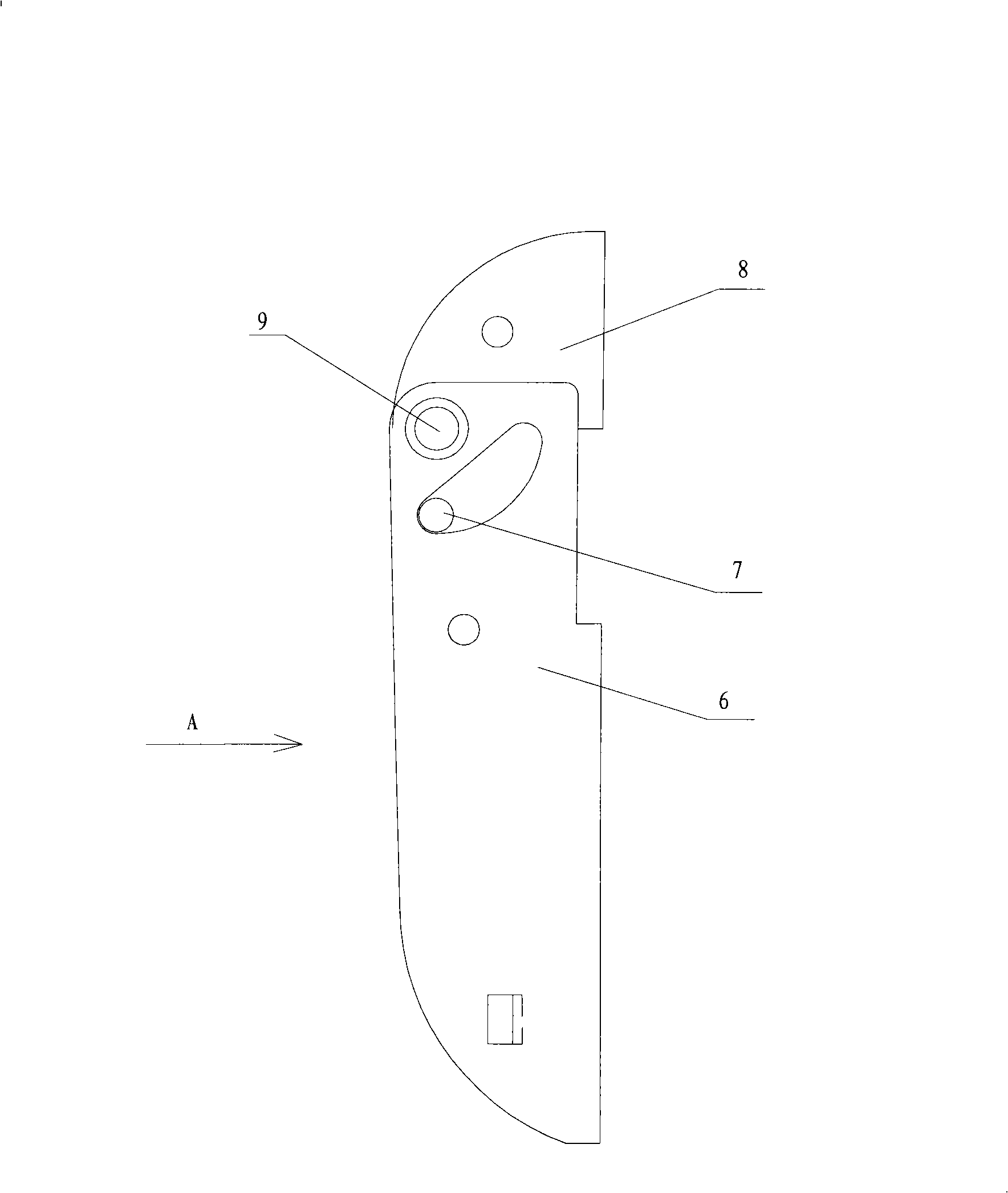

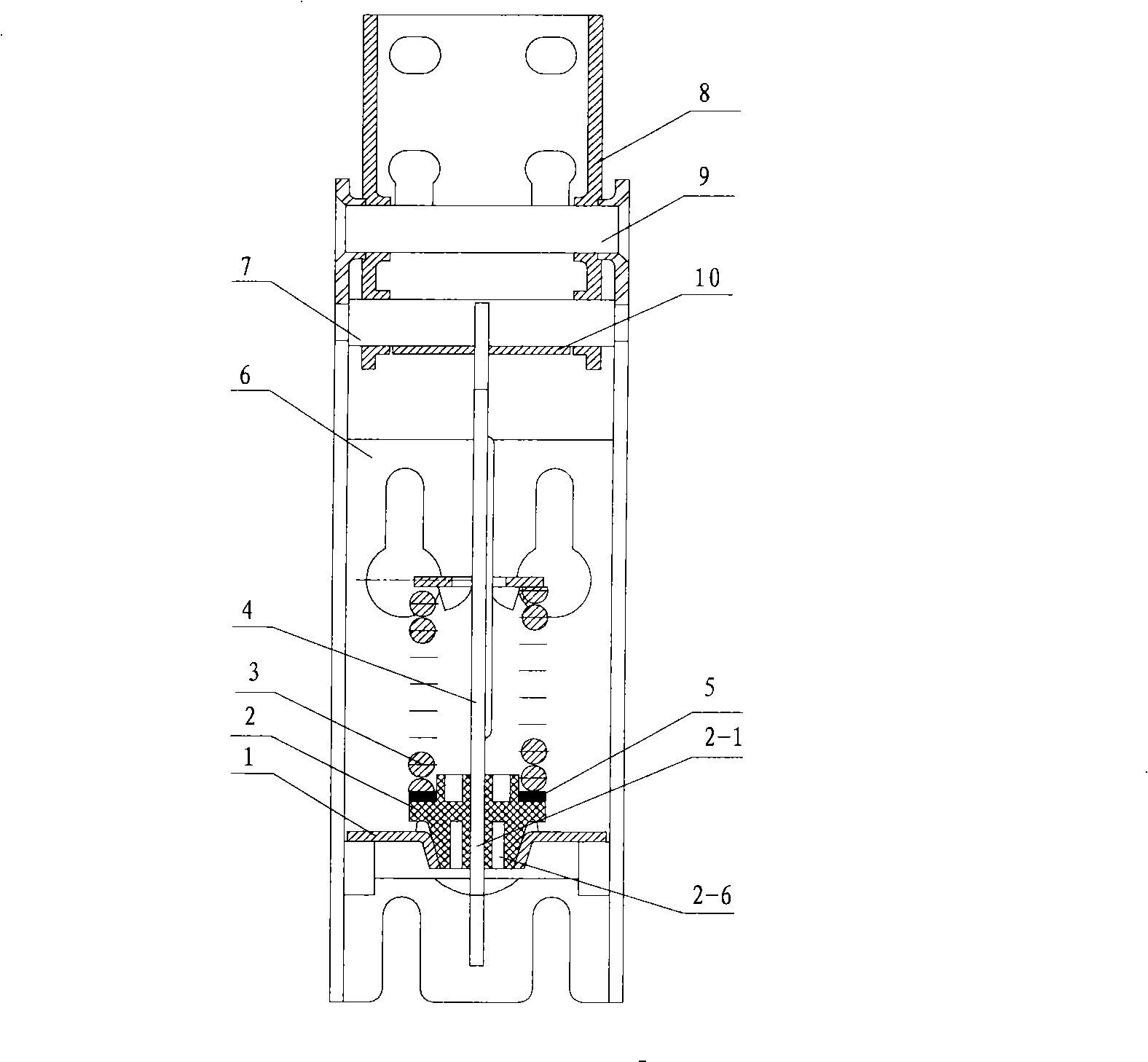

[0028] Embodiment one, such as figure 1 , 2 As shown, the balance hinge of the present invention includes a hinge shaft 9, a hinge lower shell 6 rotatable around the hinge shaft 9, a hinge upper shell 8, a guide plate 4, a spring 3, a spring lower seat 2, and a support beam fixed on the hinge lower shell 6. 1. A rocker shaft 7 is connected to the side wall of the hinge upper case 8, and the rocker shaft 7 is accommodated in the groove at the upper end of the guide plate 4, and the upper end of the guide plate 4 withstands the rocker shaft 7 by the restoring force of the spring 3. In order to avoid wear and tear, the guide plate 4 The upper end bears against the rocker shaft 7 through the bracket 10, the lower part of the guide plate 4 is inserted into the spring 3, the lower end of the guide plate 4 extends into the spring lower seat 2 and the supporting beam 1, and the spring 3 is against the stopper of the guide plate 4 and the spring lower seat 2 between. Wherein, the fi...

Embodiment 2

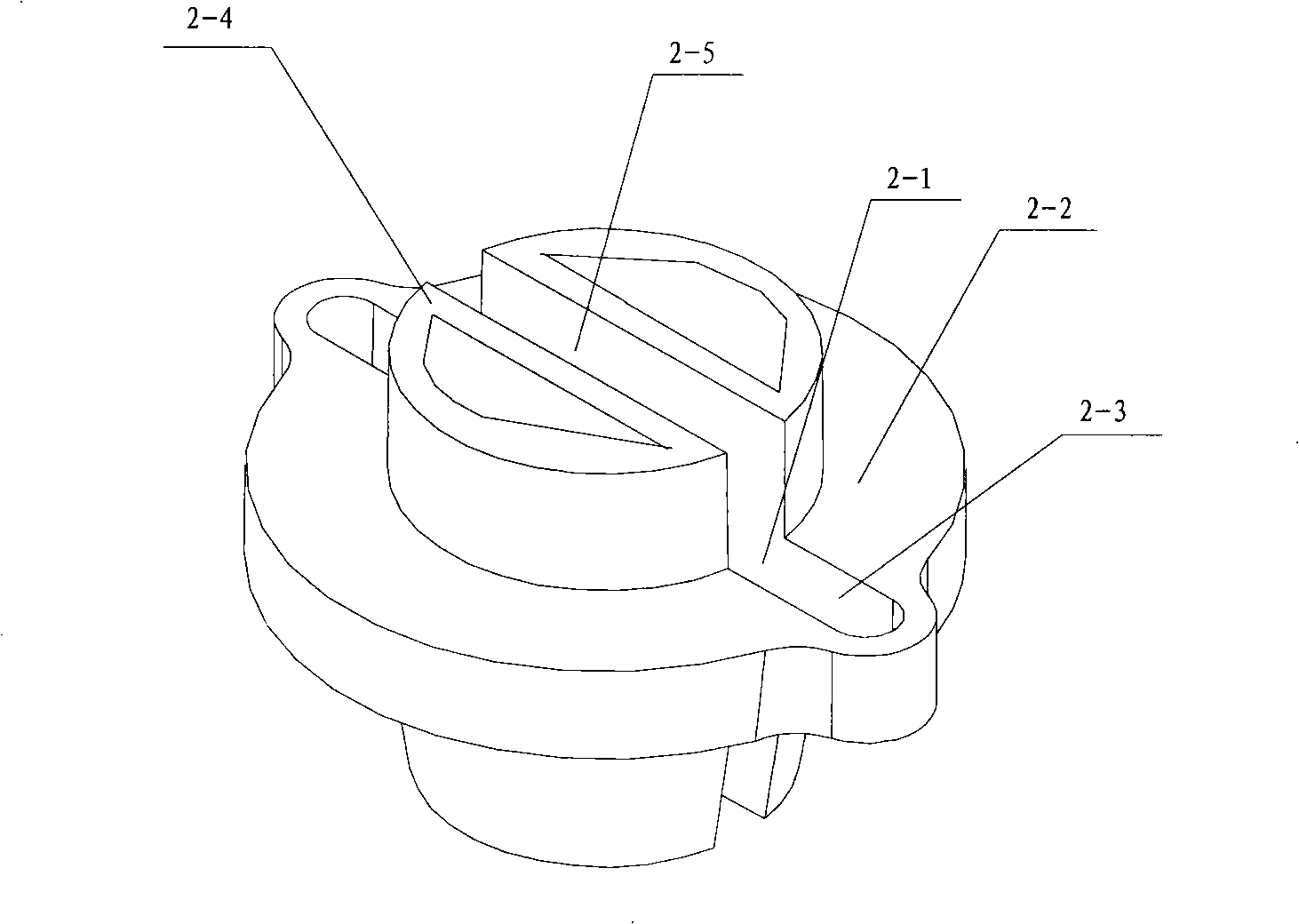

[0033] Embodiment two, refer to figure 2 , 3 , differs from Embodiment 1 in that: the top of the round platform under the spring seat 2 of this embodiment has a cylinder 2-4 consistent with the inner diameter of the spring 3, and of course it can also be other polygonal prisms, and the cylinder 2-4 has a hole along the diameter that is consistent with the inner diameter of the spring 3. The notch 2-5 communicated with the axial through groove 2-1, the lower end of the spring 3 is sleeved on the cylinder 2-4. The lower spring seat 2 of this structure can well fix the spring 3 around the guide plate 4. In order to reduce wear and tear, a washer 5 can be placed on the cylinder 2-4. In order to save labor and facilitate processing, the cylinder 2-4 also has groove on top surface.

[0034]The technical feature based on the present invention is to use the working state that the spring tends to be released when the door is opened and compressed when the door is closed, to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com