Wave power generating system

A wave power generation and wave technology, which is applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problem that the wave power generation system cannot adapt to the ebb and flow of the tide, and achieves the effect of simple structure and mature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] The wave power generation system provided by this specific embodiment is suitable to be built on a platform in shallow sea near the coast, and it mainly includes: a wave energy pickup unit, a wave adaptation unit, a motion conversion unit and a generator.

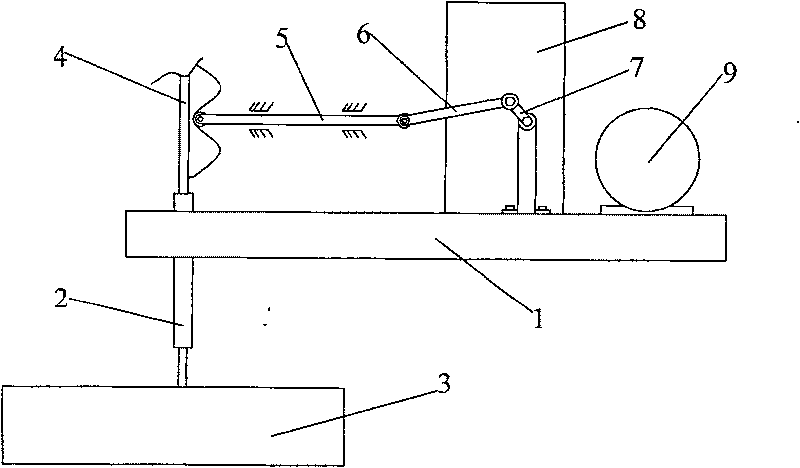

[0024] Such as figure 1 As shown, the entire system is set up on platform 1. The wave energy pick-up unit is used to pick up the energy of waves. The wave energy pick-up unit in this specific embodiment mainly includes a float 3, and the float 3 floats on the water surface below the platform 1. As the waves rise and fall, the energy of the waves is converted into up and down. reciprocating motion. The buoy 3 is power-connected with the motion conversion unit through the wave adaptation unit, transfers energy to the motion conversion unit, and is converted into rotational motion by the motion conversion unit to drive the generator to generate electricity.

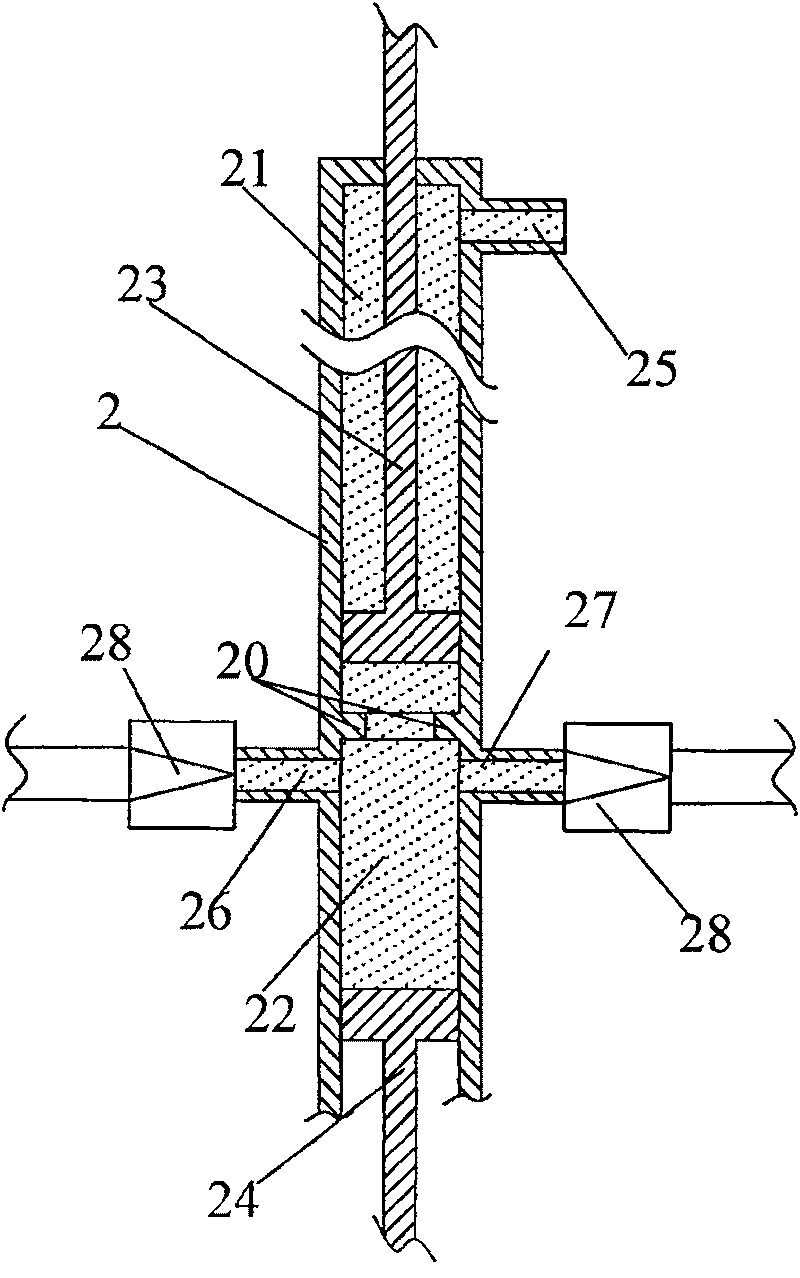

[0025] In order to adapt to the different sizes of the wave...

specific Embodiment approach 2

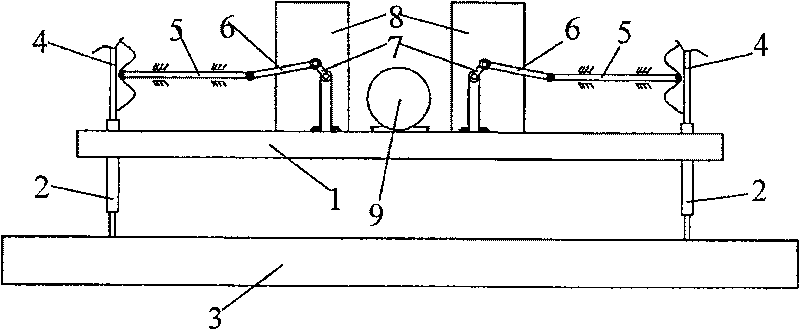

[0032] In order to make the system more optimized, the image 3 As shown, the two systems in Embodiment 1 are symmetrically arranged on one platform 1, and the two floats 3 are connected into one body, then the power is transmitted through two channels and jointly drives a generator 9 to generate electricity.

specific Embodiment approach 3

[0033] can also be like Figure 4 As shown, several groups image 3 The systems shown are juxtaposed, and the movement generated by several floats 3 drives two long crankshafts 7 after passing through their respective hydraulic telescopic rods 2 and wave mechanism 4, ejector rod 5, and rocker 6. Each crankshaft 7 A gearbox 8 is respectively connected to drive a generator 9 to generate electricity. In actual use, extend the system from the sea to the sea, and adjust the spacing between each group of units so that the spacing between every two floats 3 is about an odd multiple of half the wave pitch, and one float 3 is at the wave crest , its adjacent two floats 3 such as Figure 4 If it is exactly in the trough, the system can work together to achieve the best power generation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com