Self-heating freezing-proof overhead conductor

An overhead wire, anti-icing technology, applied in conductors, insulated conductors, climate change adaptation and other directions, can solve the problems of icing difficulties, power difficulties, unstable hydrophobic performance, etc., to reduce line maintenance costs, ensure power transmission safety, The effect of saving manpower and material resources

Active Publication Date: 2010-12-01

SHANDONG KEHONG WIRE & CABLE TECH CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in actual operation, the disadvantage of this kind of overhead wire is: since the resistance per unit length of this kind of overhead wire is constant, under the condition of constant current, it can be seen from the formula P=I2·R that its The power remains constant, that is to say, the heating value of the conductor remains constant. When encountering heavy snowfall, freezing rain and low power load, frost, ice and icicles can be formed on the overhead conductor, and even in the The surface of the overhead wire forms a thicker ice jacket, which increases the weight of the overhead wire, resulting in broken wires or towers, interrupting power transmission, bringing inconvenience to people's lives, and causing huge losses to the country

Adopt active anti-icing damage technology, that is, design overhead wires with anti-icing function. The technologies in this area mainly include the following: 1. Develop hydrophobic coatings and apply them on the surface of overhead wires. However, there are coatings in this technology. There is still a big gap in the practical engineering application of technical problems such as low coating strength and unstable hydrophobic performance of the wire; 2. The overhead wire with a special structure is not a regular circle, but in One or more aluminum single wires on the outermost layer have a certain sharp corner, and it is difficult to freeze at the sharp corner due to the small contact surface between water and it. Practical application; 3. One or more strands of low Curie temperature alloy are wound outside the overhead wire. When the temperature is low, the alloy material has high magnetic properties, and the overhead is heated by the magnetic eddy current loss generated by the current induction through the wire. Wires are used to prevent freezing, but the Curie temperature point of low Curie temperature alloys that can be prepared at present is still high, reaching 20°C, which is much higher than the freezing temperature, which will cause a large amount of power loss and low Curie temperature. The high cost of temperature alloy also limits the application of this technology

Passive deicing technology includes mechanical impact deicing technology and electrical heating deicing technology: mechanical impact deicing technology may cause mechanical damage to overhead wires and reduce the life of overhead wires, and should generally be avoided as much as possible; electrical deicing technology One is to use a special structure overhead conductor in which the steel core and the aluminum stranded wire are separated by a layer of cross-linked polyethylene insulation. The core resistance is large, and the power loss per unit length is large, thus playing the role of heating and deicing; the second electrical deicing technology is to use a movable generator to provide AC or DC power to the frozen ice under the condition of power failure. A certain section of the overhead wire is heated and deiced. Due to the geographical constraints of the overhead wire line, it is very difficult to carry a heavy power supply, which also limits the application of this technology.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

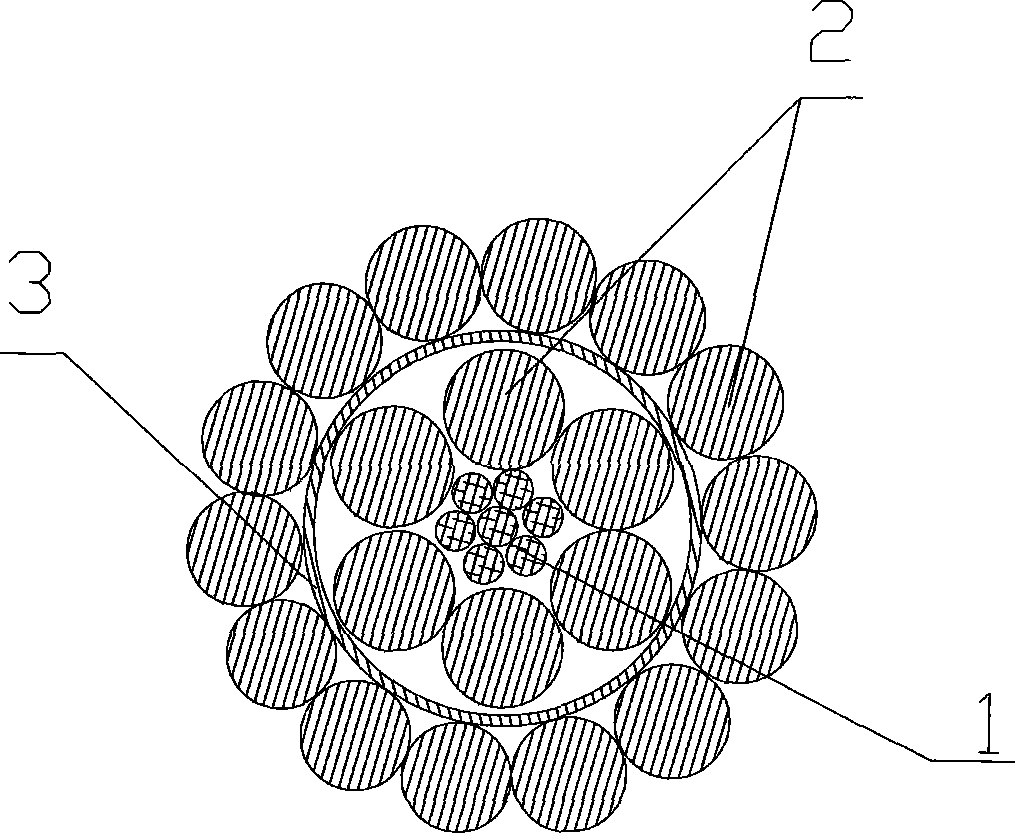

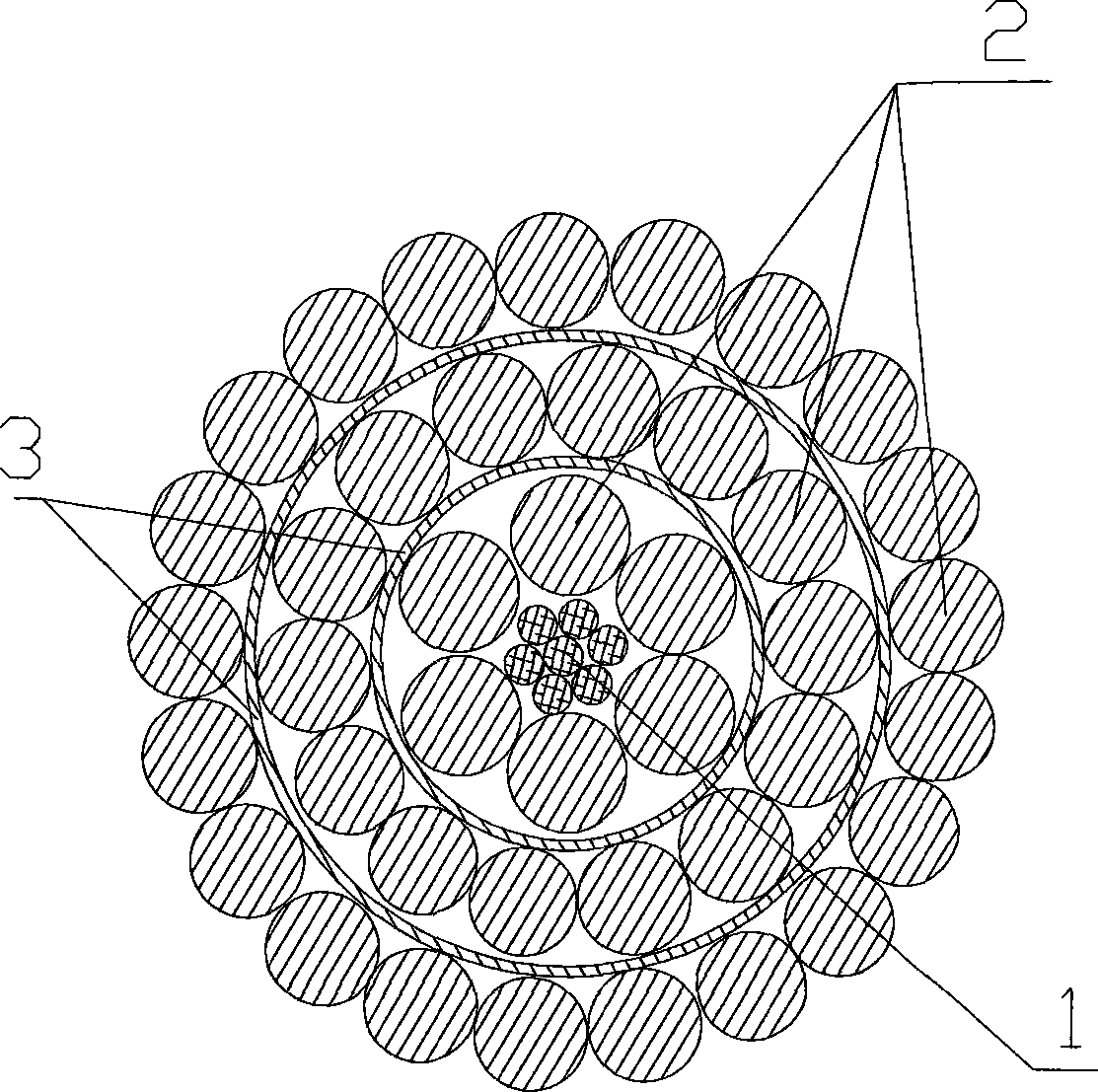

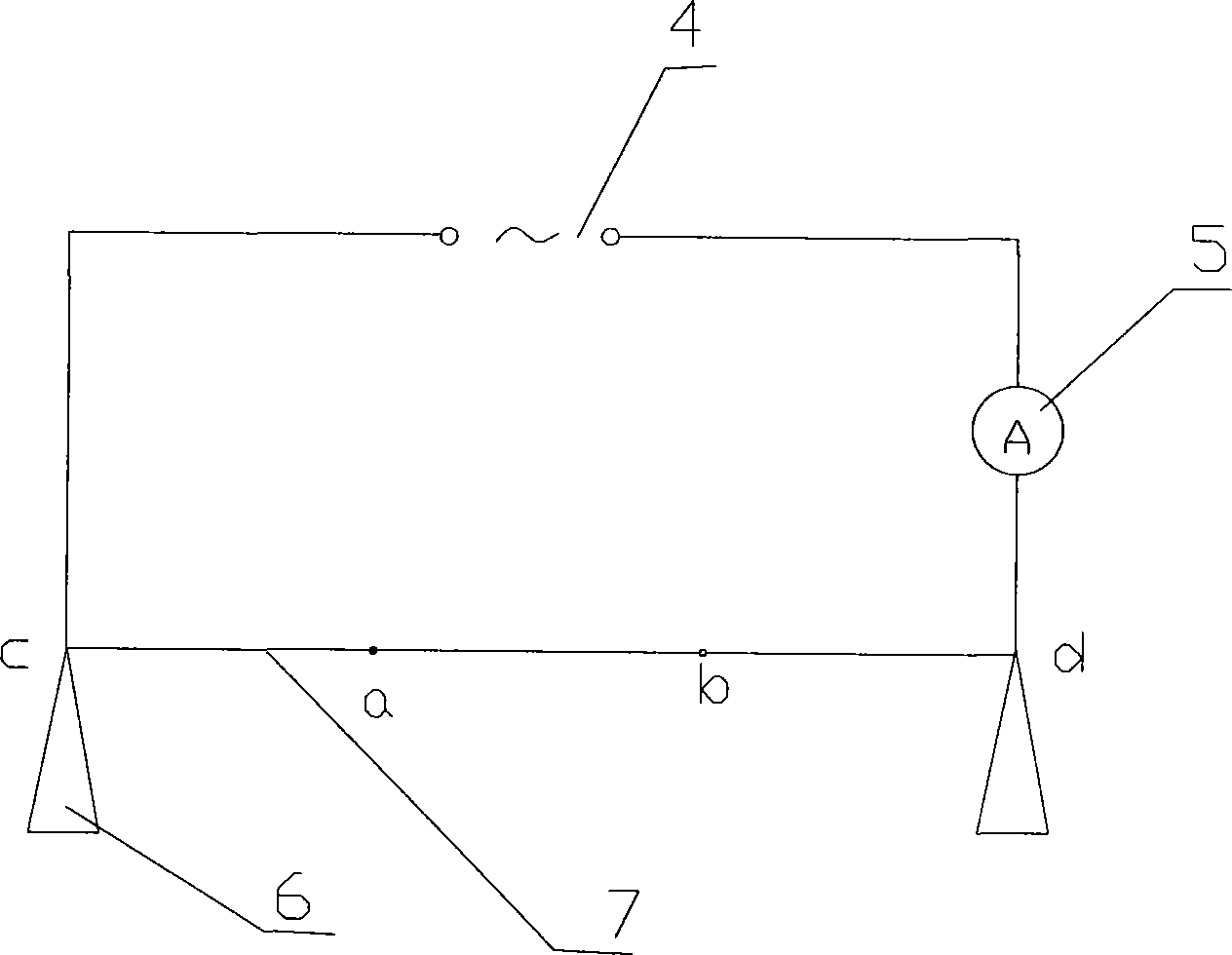

The invention discloses a self-heating and anti-icing overhead conductor, belonging to the technology field of overhead conductors in electric power industry; the overhead conductor consists of a conductor core (1) and a stranded conductor (2). The conductor core (1) adopts a galvanizing steel wire while the stranded conductor (2) is an aluminum conductor and is stranded on the outside of the conductor core (1). The overhead conductor is characterized in that an insulating layer (3) is arranged between layers of the stranded conductor (2). The insulating layer (3) with a thickness of 0.3 to 0.5mm is provided with 1 to 2 layers and formed by winding insulating beltings for wrapping. Compared with the overhead conductor in prior art, the self-heating and anti-icing overhead conductor can beheated by changing the electrifying section area, so the overheard conductor can be automatically heated to remove the ice layer on the surface of the overhead conductor and assure power transmissionsafety. Meanwhile, the overhead conductor has simply structure, can save the labor and material for the maintenance of lines, lower the cost for the maintenance of lines and be extensively applied tothe power transmission with a voltage of over 35 KV.

Description

Self-heating anti-icing overhead conductors technical field The invention relates to an overhead wire for electric power, in particular to a self-heating anti-icing overhead wire. Background technique Most of the existing power overhead conductors are composed of wire cores and stranded wires. The wire cores are generally made of galvanized steel wires, which play a tensile role. The stranded wires are aluminum wires, which are stranded outside the wire cores and used for long-distance transmission of high-voltage power. . The overhead conductors with this structure can meet the requirements of safe power transmission in the non-freezing season or in the weather without wind and snow. However, in actual operation, the disadvantage of this kind of overhead wire is: since the resistance per unit length of this kind of overhead wire is constant, under the condition of constant current, it can be known from the formula P=I2·R that its The power remains constant, that is to s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B7/28H01B7/42

CPCY02A30/14

Inventor 李忠华商传红臧化文

Owner SHANDONG KEHONG WIRE & CABLE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com