Production process for manufacturing cement fibre board from fast growth aspen

A technology for cement wood wool board and production process, which is applied in the direction of manufacturing tools, cement mixing devices, wood processing appliances, etc., can solve the problems of unfavorable small and medium-sized enterprises to invest in setting up factories, high prices, and large space occupation, so that the space occupation is not large. , the output is convenient, the effect of less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

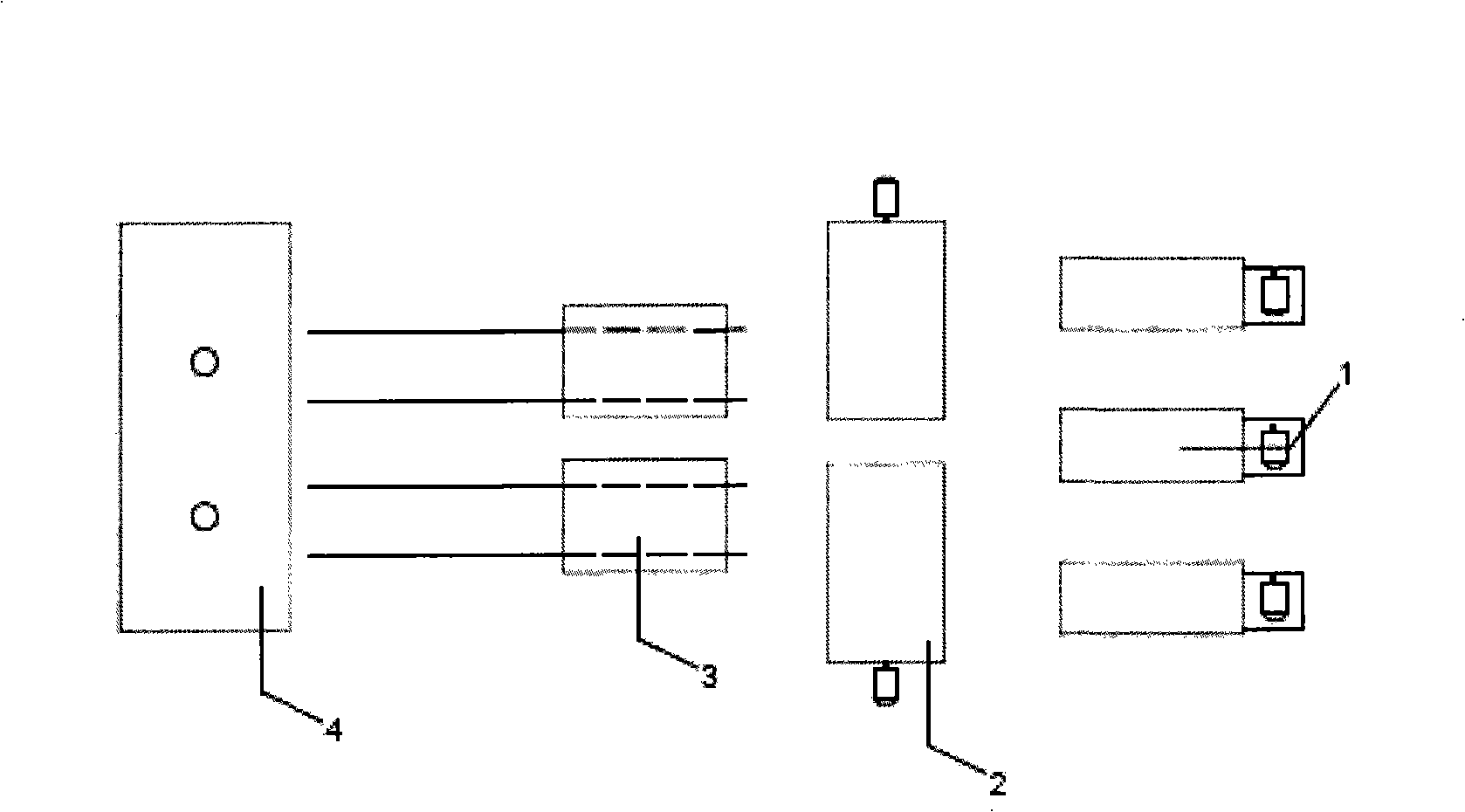

[0017] As shown in Figure 1, a schematic diagram of a production line for making cement wood wool board with fast-growing poplar. One production line mainly consists of three shredders 1, which have been granted a patent, the patent number is ZL200620049449.8, and two purchased shaft mixers 2 , two paving lines 3, and a cold press 4. Taking the cement wood wool board with a production specification of 1200mm×600mm and a thickness of 25mm as an example, the specific production steps are as follows.

[0018] The grater slices the 250mm long poplar into wood fibers with a width of 2mm and a thickness of 0.2-0.5mm. The measurement process is to weigh 2.0Kg of wood wool and 5Kg of cement required for each board, and the cement uses decorative white cement with a strength grade of 42.5Mpa. In the mixing process, the impregnated wood wool and cement are put into the mixing tank and mixed for 5 minutes. The pressing process controls each stack of molds to be 20 pieces. Concrete cube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com