Steam chamber cloth feeding port dripping-proof device

An anti-drip, cloth inlet technology, applied in the processing of textile materials, textiles and papermaking, textile processing machine accessories, etc. The process is convenient and the effect of ensuring the quality of steaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

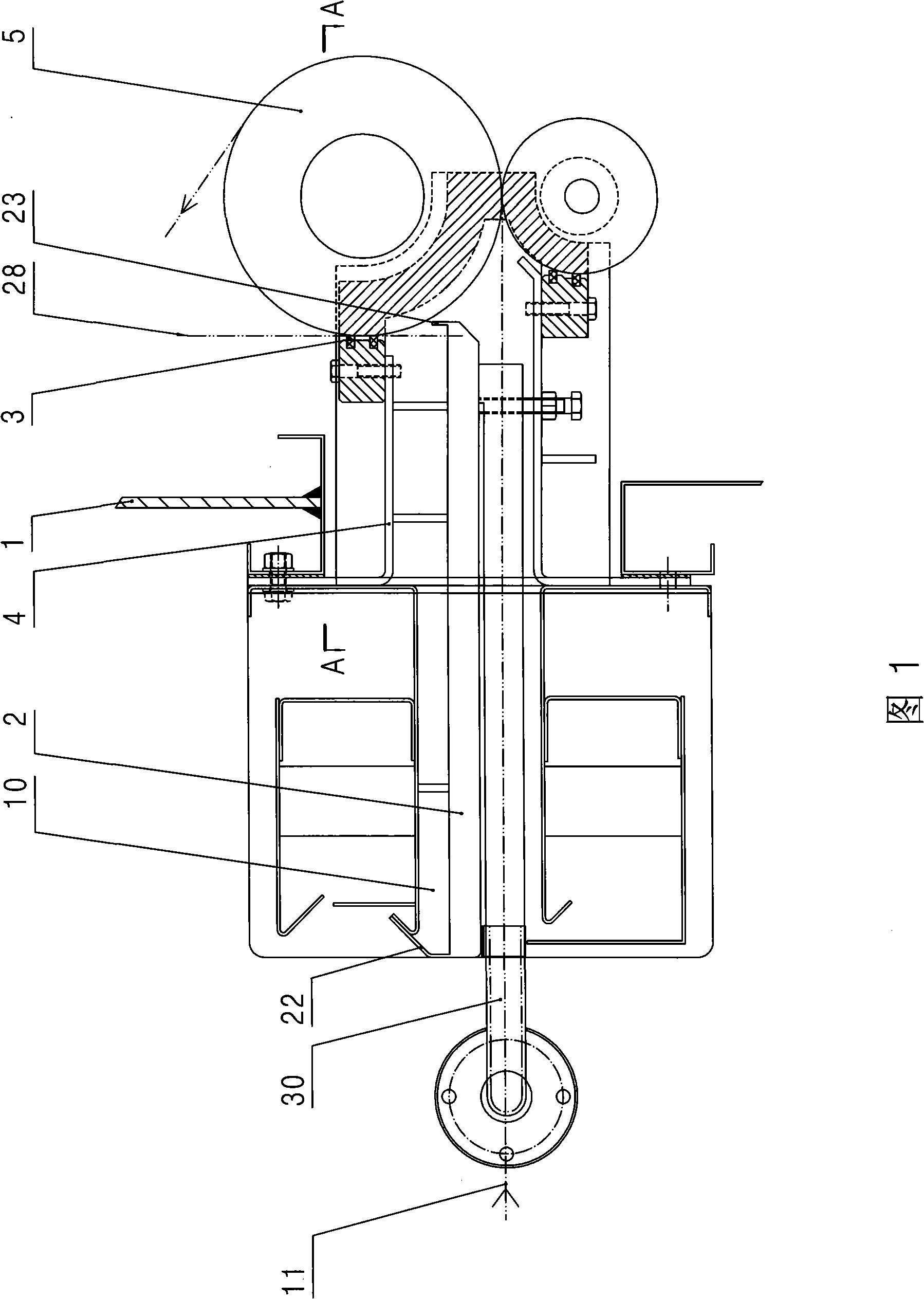

[0021] The technical solution of the present invention, its working principle and advantages will be further described below in conjunction with the accompanying drawings:

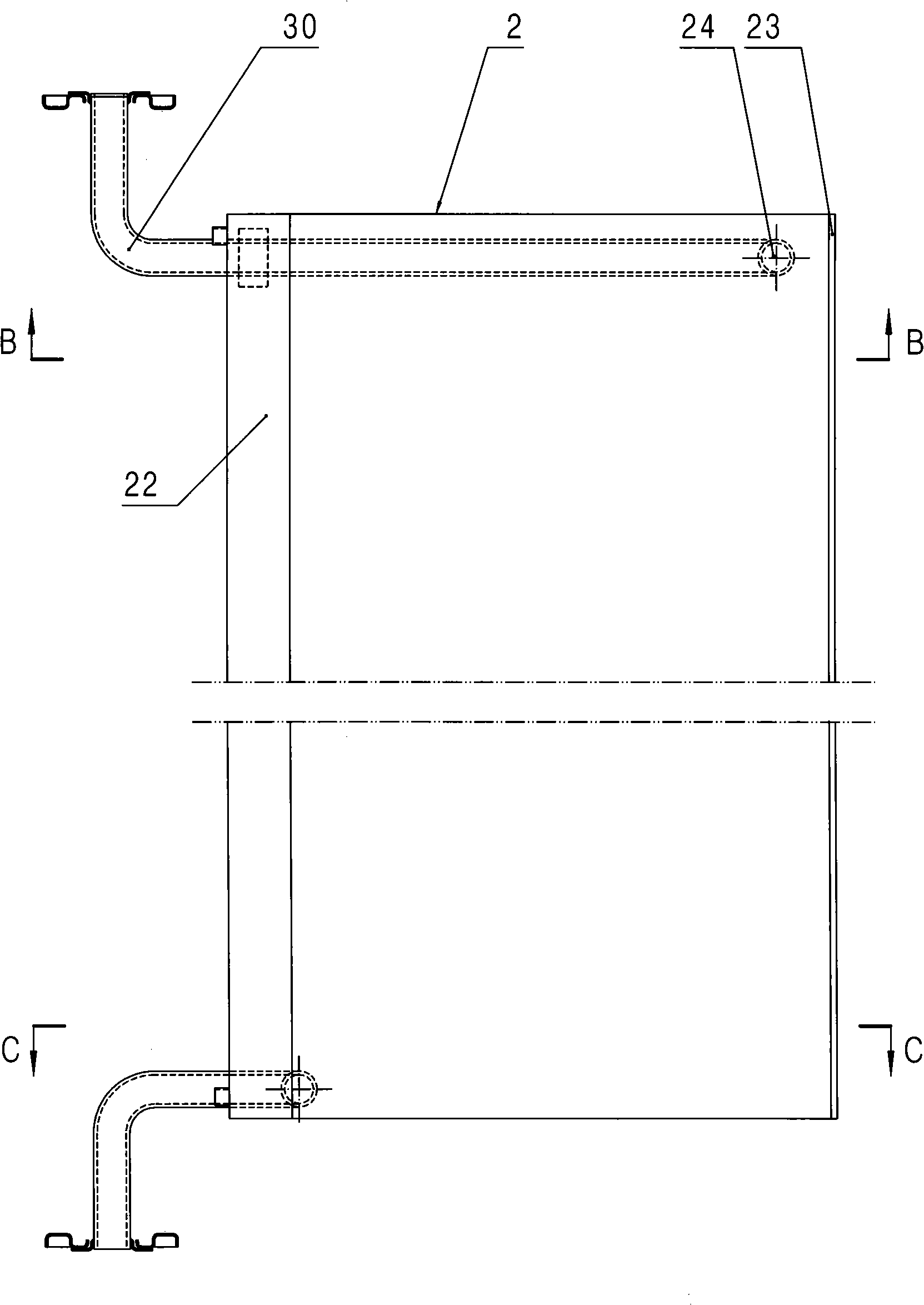

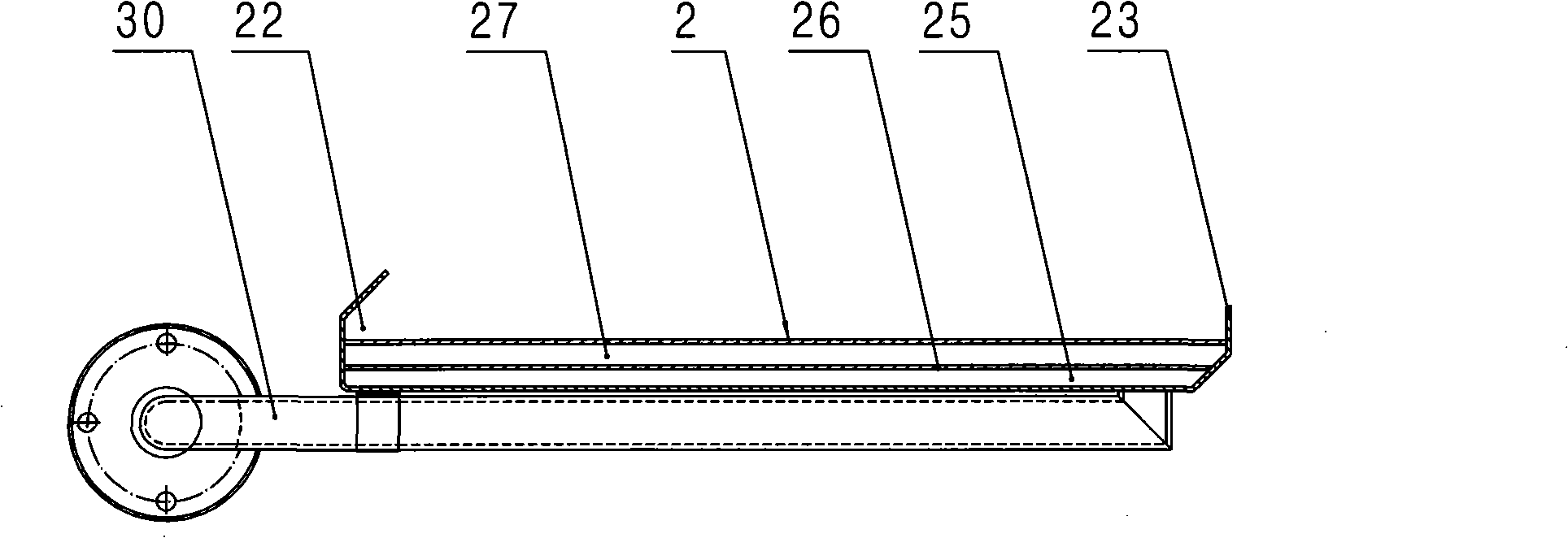

[0022] As shown in Figure 1, the anti-drip device of the cloth inlet of the steam box according to the present invention includes: an anti-drip board 2 arranged in the cloth inlet 10, the width of the anti-drip board 2 is not less than the width of the fabric 11 , the outer edge of the anti-drip plate 2 is not shorter than the outer edge of the cloth inlet 10, the inner edge of the anti-drip plate 2 extends into the box body 1, and stretches through the upper side plate 4 of the cloth inlet sealing cavity and the steam The sealing surface 28 of the roller surface seal between the cloth feeding guide rollers 5 in the box body 1 is the sealing surface 28 between the upper side sealing strip 3 and the cloth feeding guide roller 5 shown in FIG. 1 . like figure 2 , image 3 , Figure 4 As shown, a specific s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com