Optical fiber connector

A fiber optic connector and connector technology, applied in the direction of instruments, optics, light guides, etc., can solve problems such as stress concentration, optical signal bending loss, main cladding damage, etc., and achieve the effects of preventing cracking, reliable protection, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

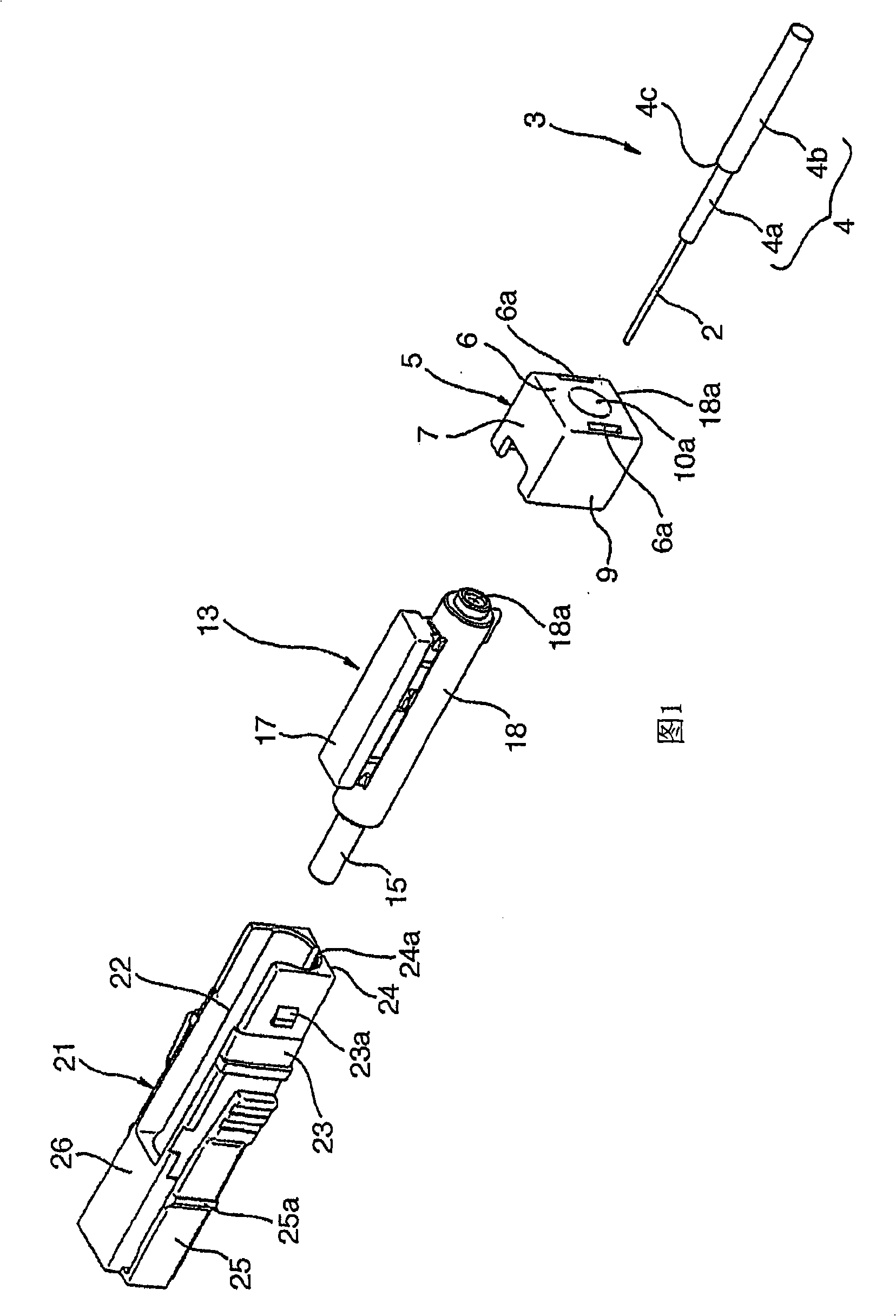

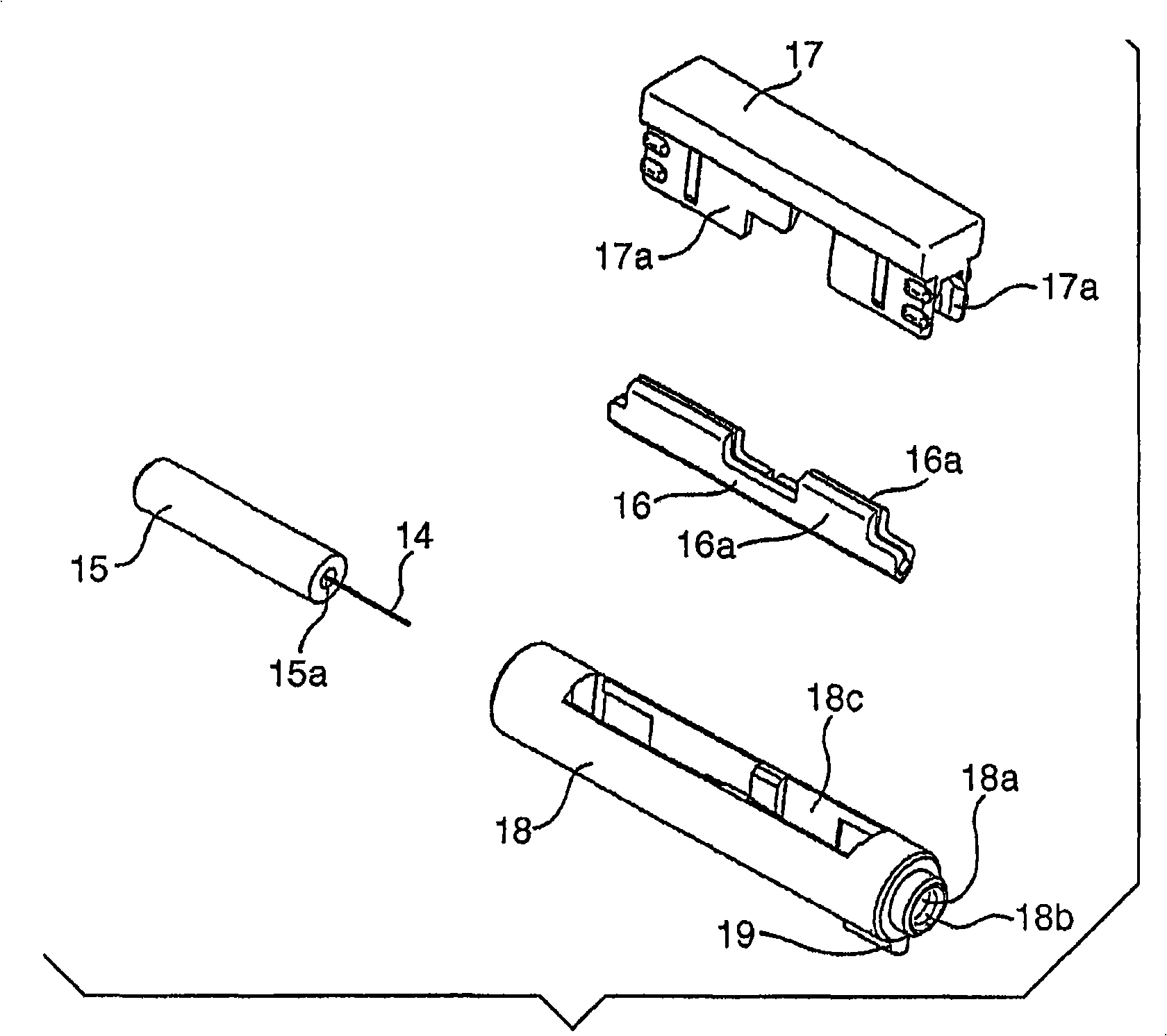

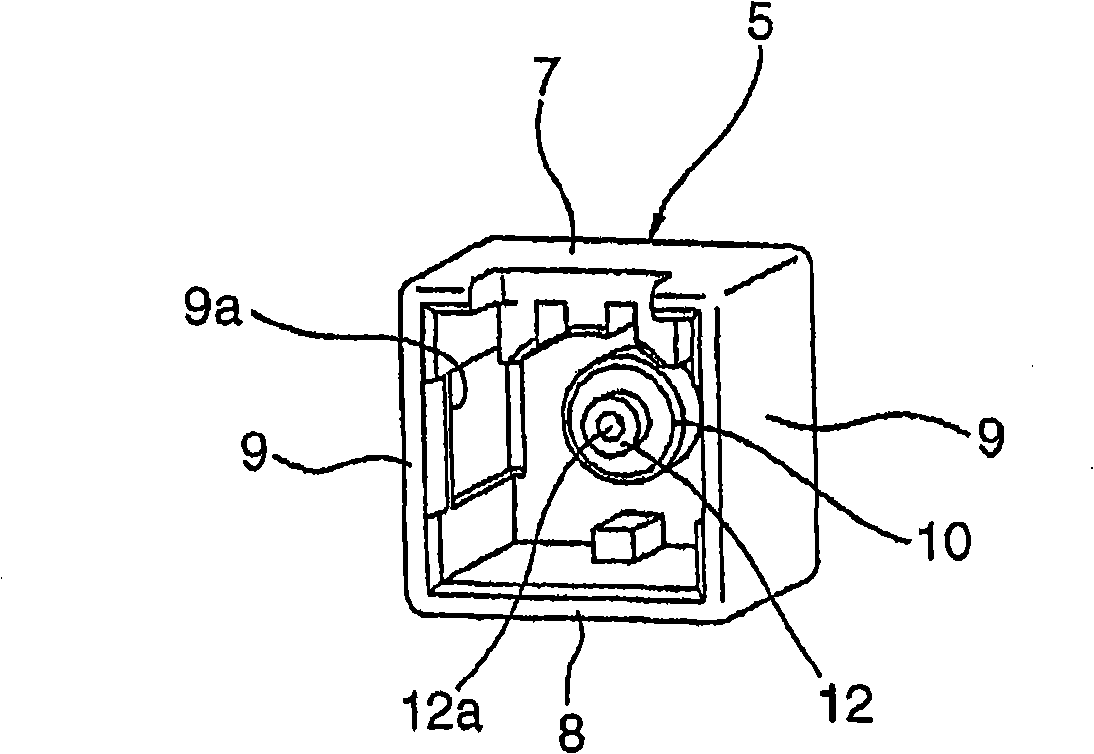

[0025] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Figure 1 is an exploded perspective view of one embodiment of the fiber optic connector of the present invention. According to this embodiment, the optical fiber connector 1 includes: a main cladding part 3 formed by covering the outer circumference of the bare optical fiber part 2 with a layered structure inner cladding 4; Cover 5; a splice assembly 13 for adjoining the end face of the bare optical fiber portion 2 and optically connecting thereto; Engaged connector housing 21 .

[0026] The main cladding part 3 is formed by removing the thick outer covering of its cladding from the optical fiber cable, which consists of a bare optical fiber part (glass optical fiber) and an inner covering 4 of a multilayer structure covering the optical fiber . The inner cover member 4 of a multilayer structure is formed by a method of repeatedly using a resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com