Bioreactor and method for the biological purification of water

A bioreactor and water purification technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve problems such as blocked openings, weakened air supply, and hindering the use of small-sized carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

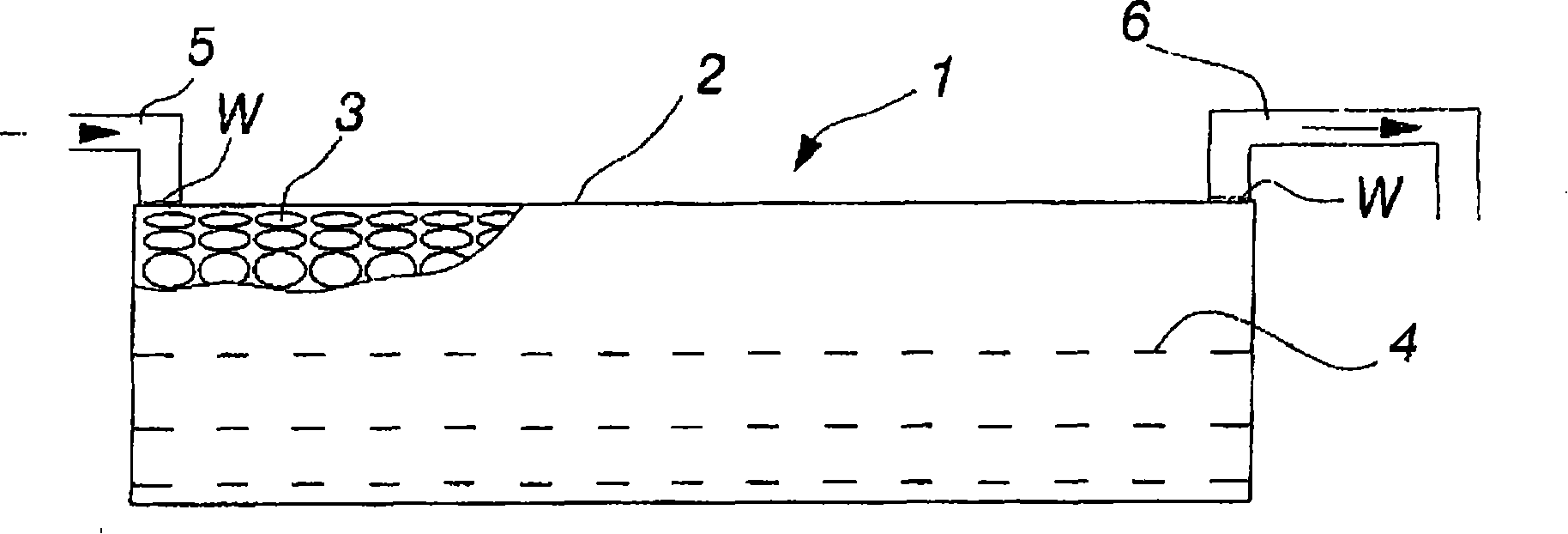

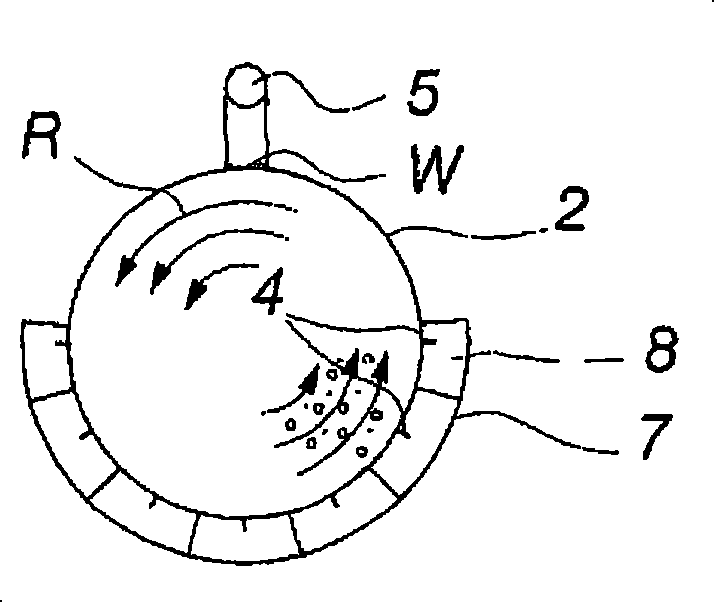

[0017]As shown, the bioreactor 1 of the present invention comprises a tubular vessel part 2, which is preferably circular or elliptical in cross-section. Said container part 2 is provided with inlet means 5 for the water to be purified and outlet means 6 for the purified water, and means 4 for supplying a fluid containing the reaction gases required for the purification process, preferably in such a way that the water to be purified Bubbles containing reactive gases are generated to supply, for example, the air required for an aerobic purification process in the form of air bubbles from which the air dissolves into the water to oxidize the water to be purified for bacterial activity. The fluid may also consist of pre-aerated water in which the air is present in the form of air bubbles and / or in a pre-dissolved form to provide oxygen-enriched water. In said case, described by way of example only, the inlet means 5 and outlet means 6 for water are arranged at longitudinally oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com