Production schedule forward scheduling system and method

A technology of production planning and scheduling, applied in the direction of calculation, instrumentation, data processing applications, etc., can solve problems such as large orders, unreasonable, images, etc., and achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

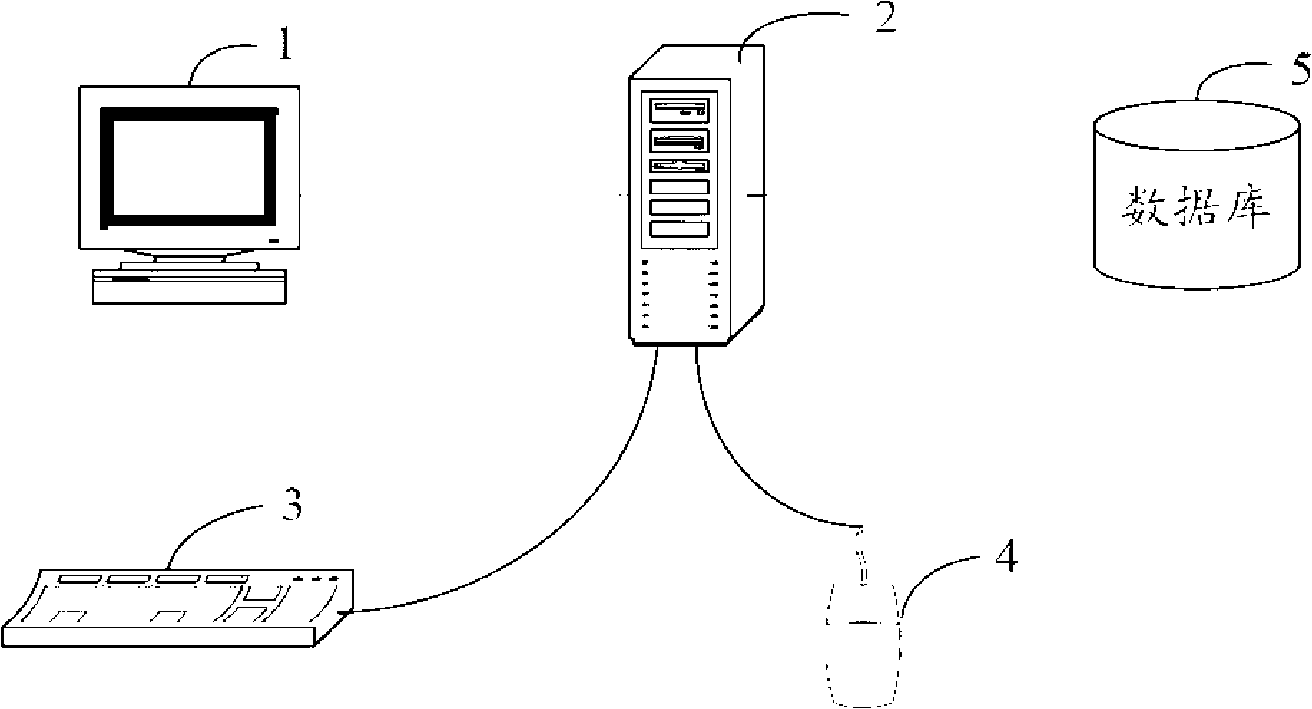

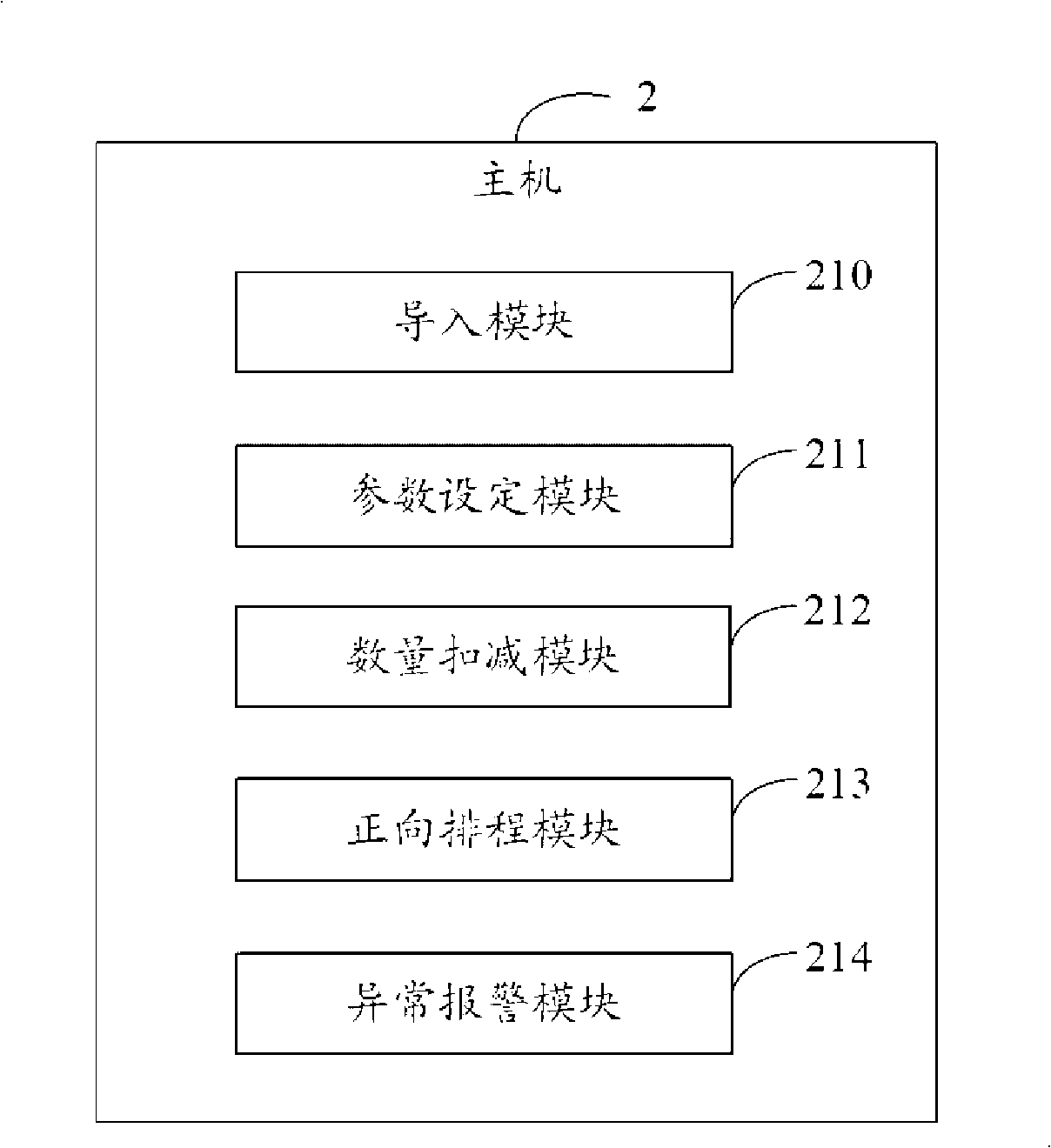

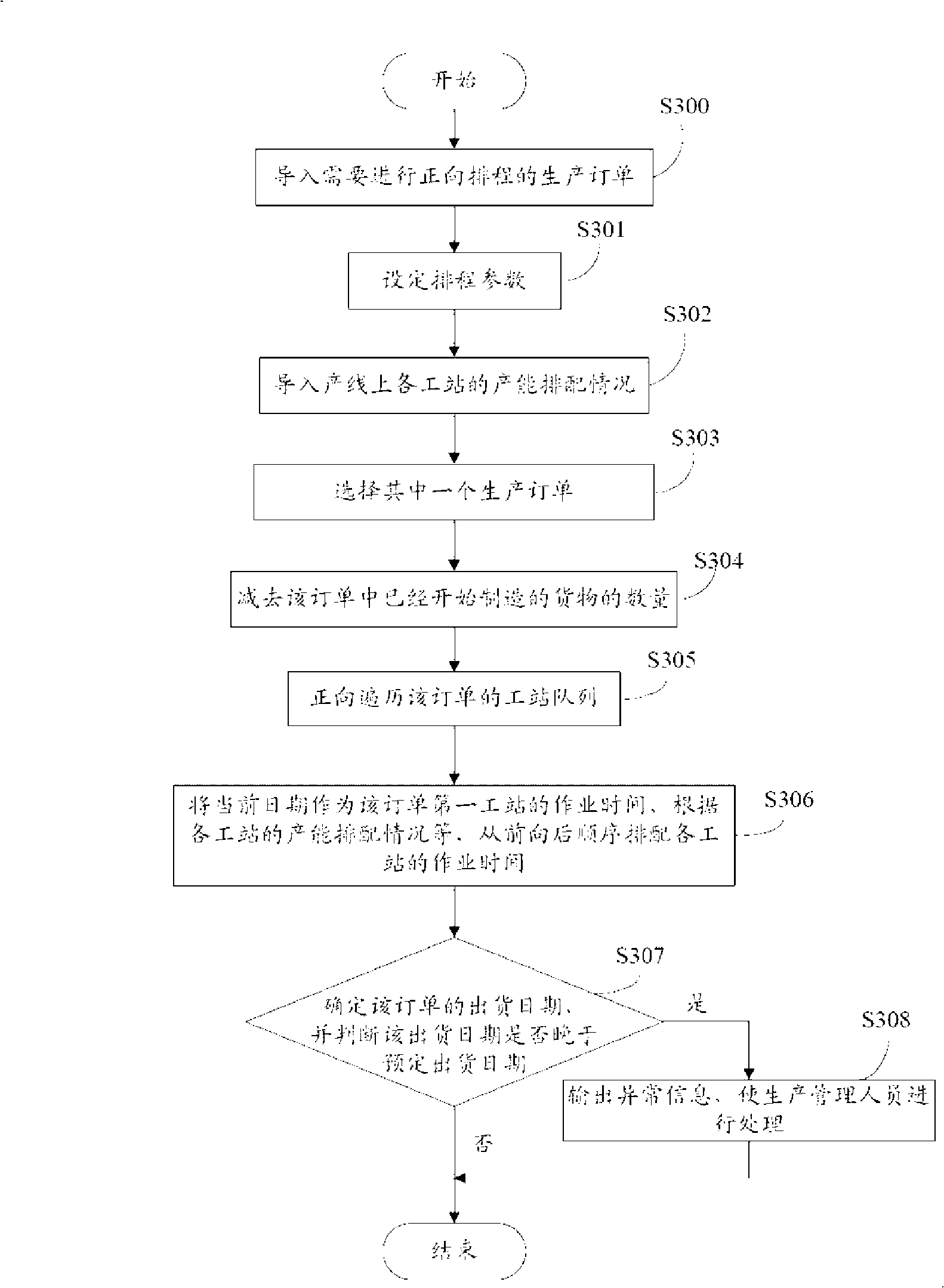

[0013] Such as figure 1 Shown is a system architecture diagram of a preferred embodiment of the production planning forward scheduling system of the present invention. The system mainly includes a display 1 , a host 2 , a keyboard 3 and a mouse 4 , and the host 2 is connected with a database 5 . The database 5 stores the production orders of customers and the production capacity allocation of each station on the production line of the enterprise. Multiple production orders of multiple customers can be stored in the database 5, and each order can include: the type of goods ordered, the quantity required by the order, the workstations to be passed through for processing the goods ordered, the order of the workstations and the order reservation Shipping time and other information. The production capacity allocation of the workstation may include: the average production capacity of the workstation, the maximum production capacity of the workstation, the number of machines includ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap