High-capacity direct current de-icing device

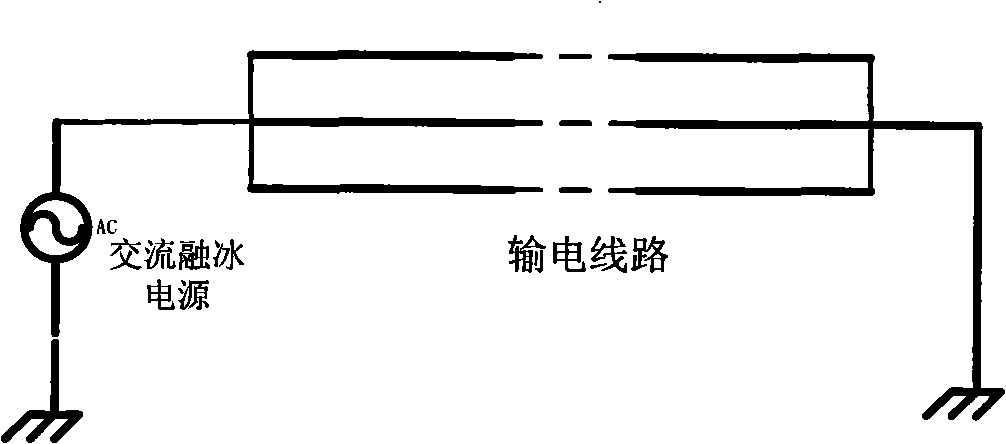

A DC ice melting, large-capacity technology, applied in the output power conversion device, AC power input is converted into DC power output, irreversible AC power input is converted into DC power output, etc. problems such as poor production, real-time and rapidity, to meet the needs of ice melting and facilitate transportation and movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

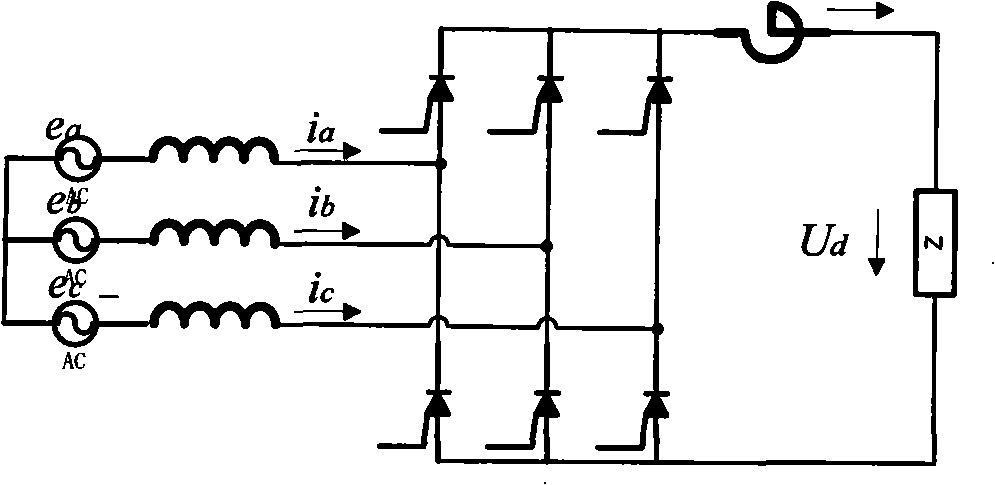

Method used

Image

Examples

Embodiment approach

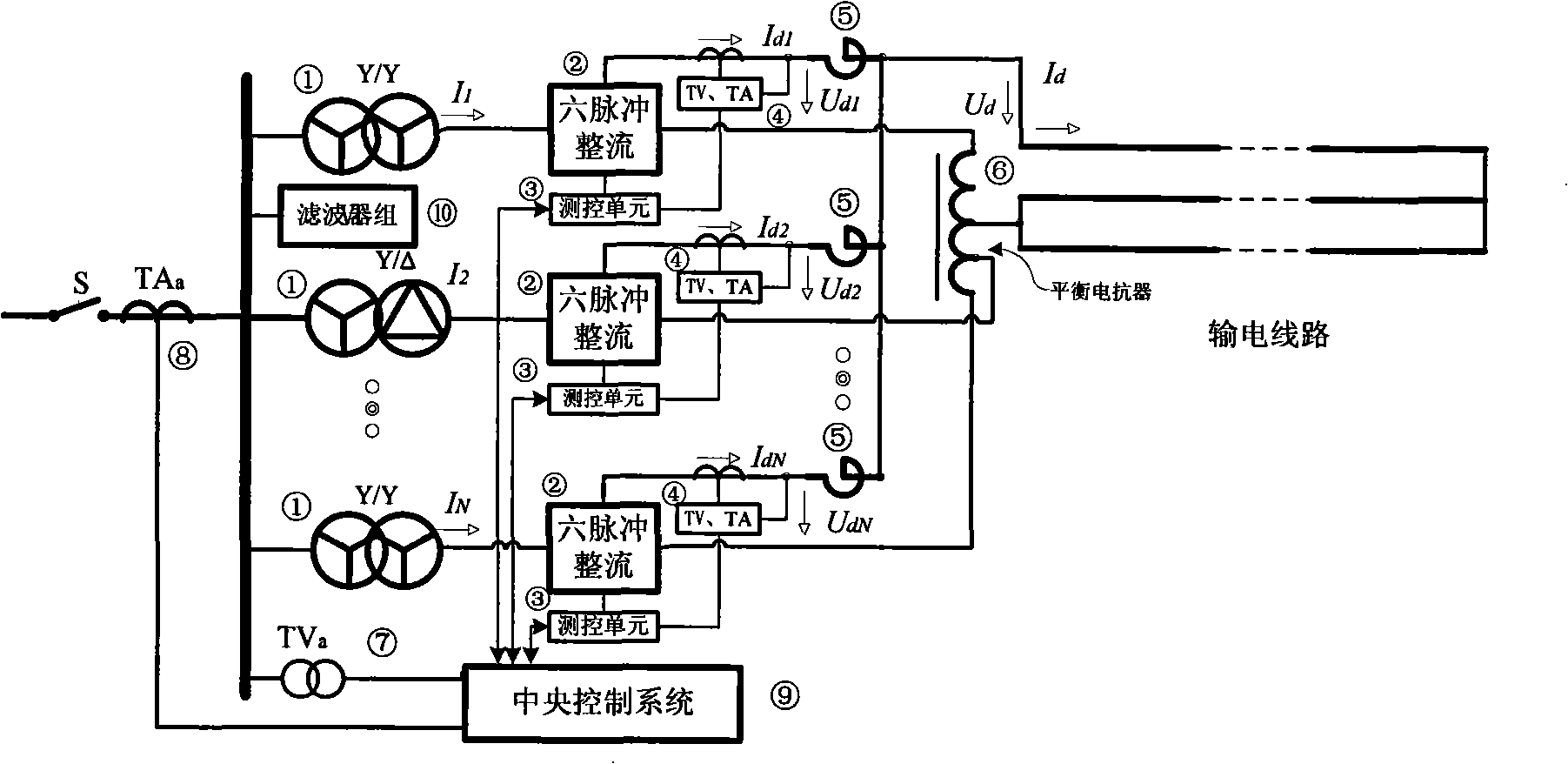

[0048] see image 3 . The embodiment of the present invention is: a large-capacity DC ice-melting device, which is characterized in that it includes a rectifier transformer ①, a six-pulse rectifier ②, a measurement and control unit ③, a DC voltage, a current transformer TV, TA ④, a DC smoothing reactor ⑤, Balance reactor ⑥, AC voltage transformer TV a ⑦, AC current transformer TA a ⑧ and central control system ⑨;

[0049] It has N six-pulse rectifiers ② with the same parameters, N is greater than or equal to 2, and N measurement and control units ③ provide trigger pulses for each six-pulse rectifier ② independently, and simultaneously collect the signals of DC voltage and current transformer TV, TA ④ for analysis and calculation The output voltage and current value of the six-pulse rectifier ②; the input end of the DC ice-melting device is equipped with an AC voltage transformer TV a ⑦, AC current transformer TA a ⑧, its output is connected to the central control system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com