Reel tape type linear electric motor

A linear motor and tape measure technology, applied in electrical components, electromechanical devices, mechanical equipment, etc., can solve the problems of inability to achieve high-precision control, complex structure, and high cost, and achieve the effects of large implementation value, small size, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

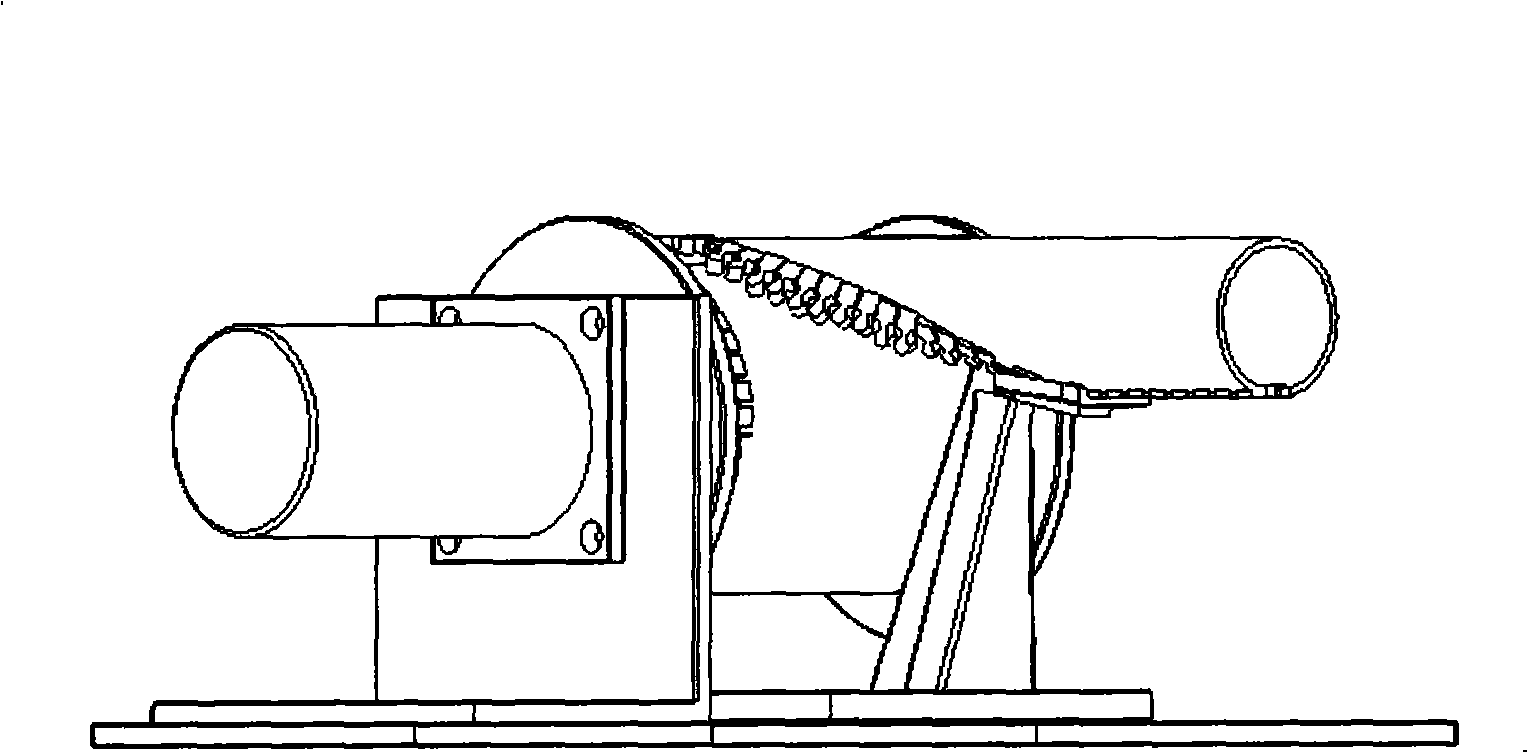

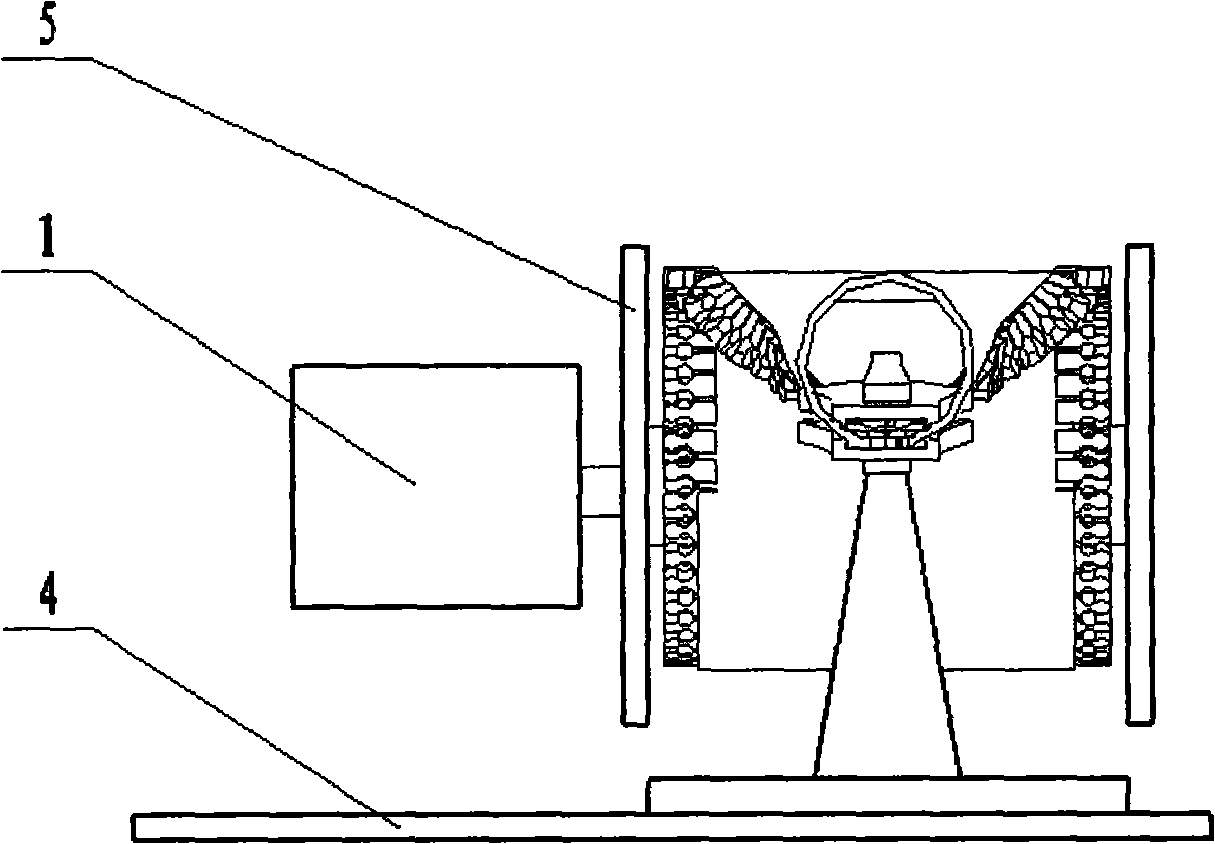

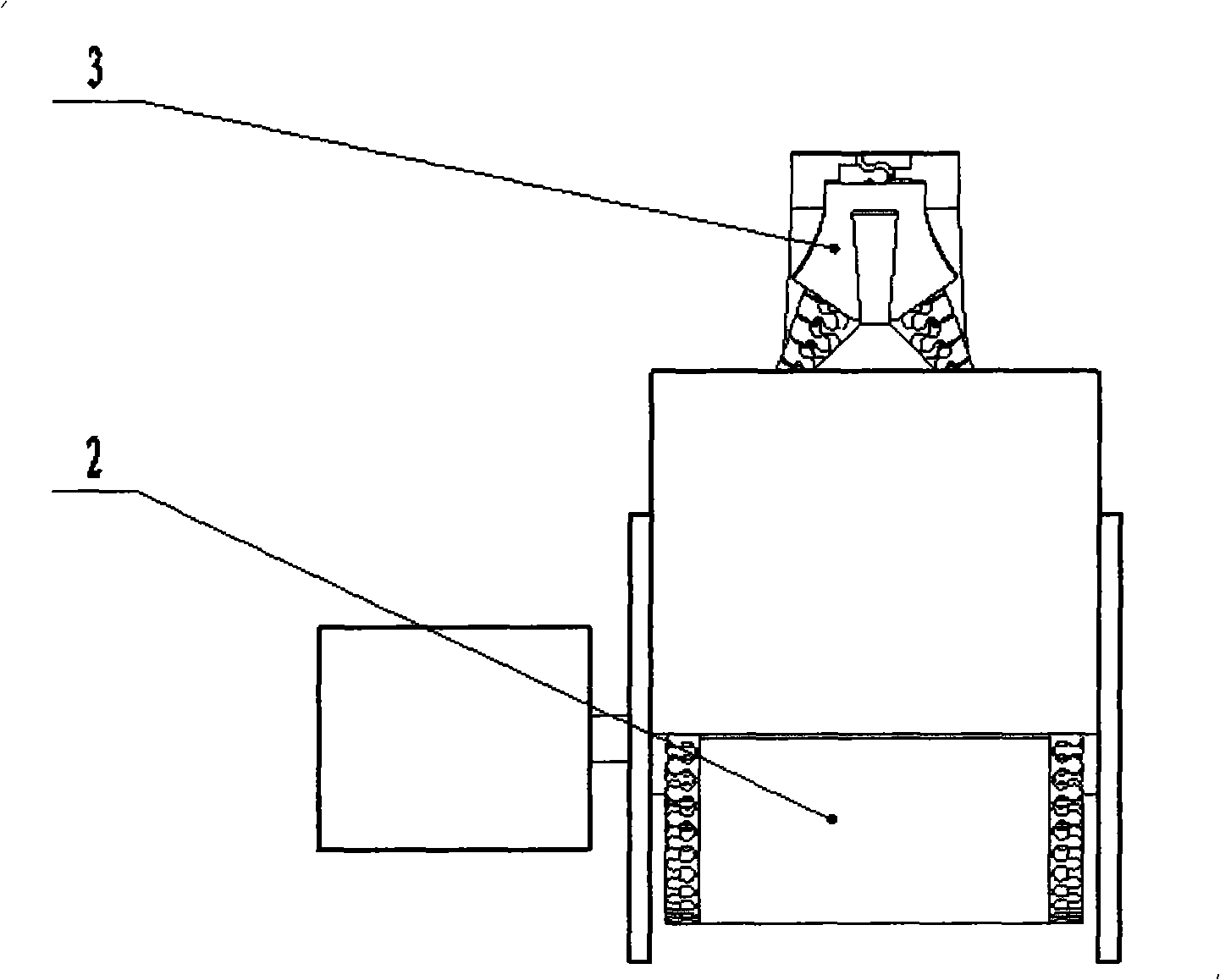

[0025] refer to Figure 1 to Figure 9 , a tape measure type linear motor, comprising a rotary motor 1, a motor base 4, a thrust plate 2 and a thrust plate reel 5, the rotary motor 1 is installed on the motor base 5, and the thrust plate reel 5 is installed on the motor On the base 4, the output shaft of the rotating motor 1 is connected to the central shaft of the thrust plate reel 5, the thrust plate 2 is coiled on the thrust plate reel 5, and the end of the thrust plate 2 is connected to the thrust plate reel 5. The central axis of the wheel 5 is fixedly connected, and the thrust plate 2 also includes an output end connected with the controlled mechanism.

[0026] The thrust plate 2 is a cylindrical thrust plate that can be radially bent, the two sides of the thrust plate 2 are provided with zipper teeth, the linear motor also includes a zipper head 3, a bracket, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com