Lifting ring structure used for shock absorber

A shock absorber and suspension ring technology, which is applied to springs/shock absorbers, springs made of plastic materials, springs, etc., can solve the problems of hard rubber layer and reduced floating performance, so as to achieve distributed stress, uniform force, and avoid The effect of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

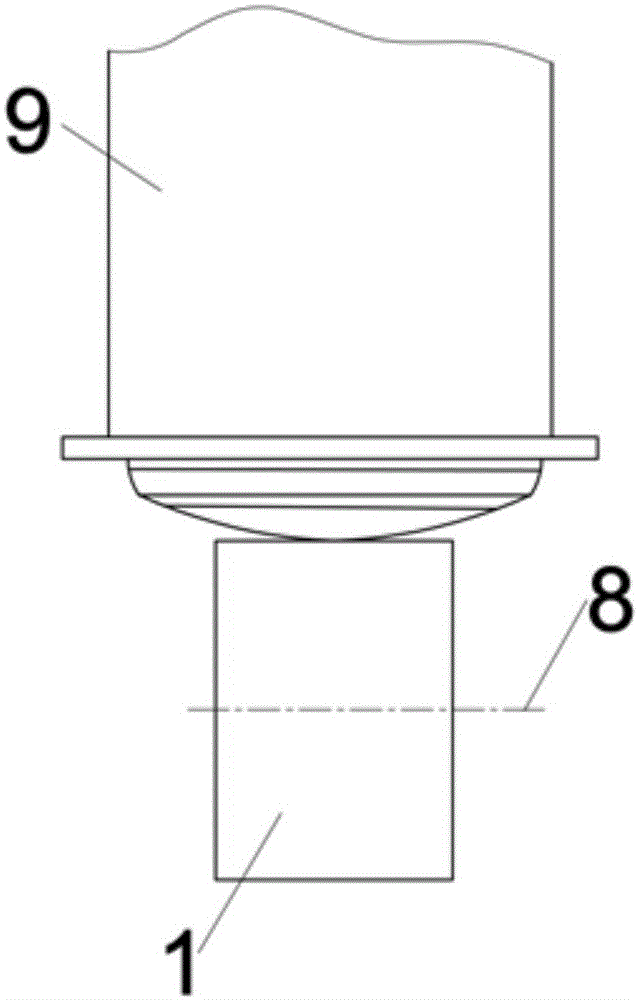

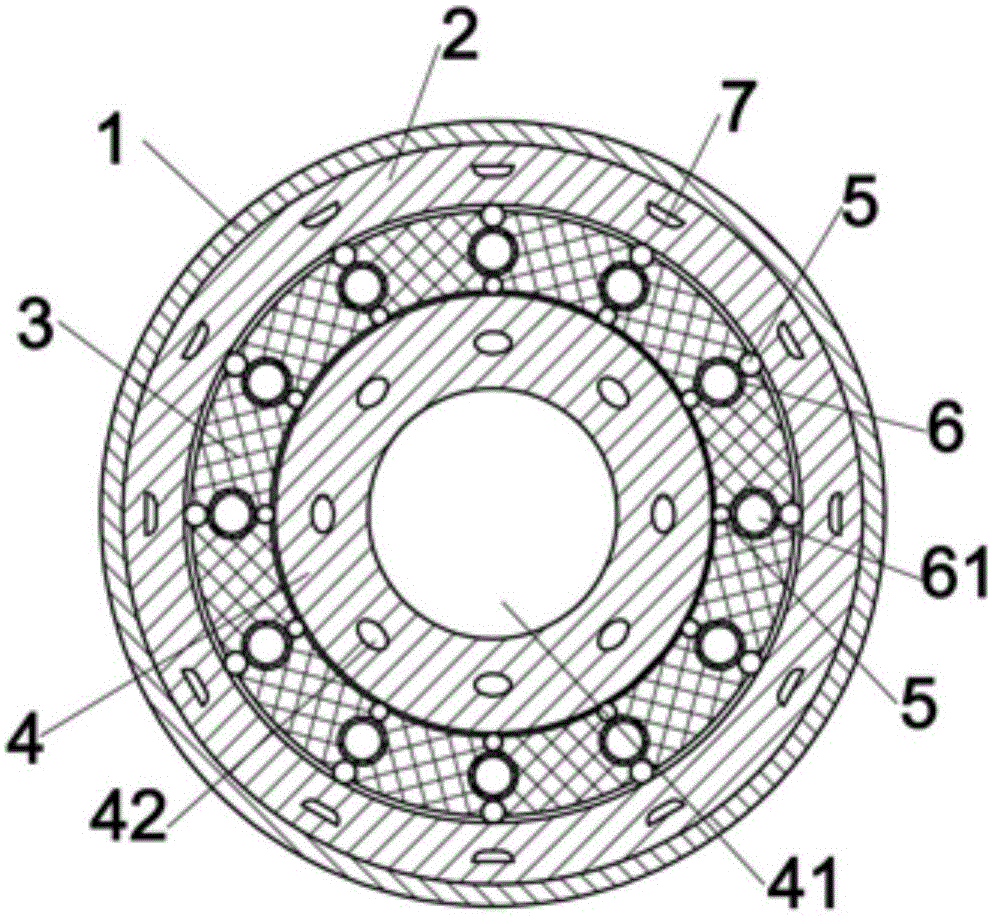

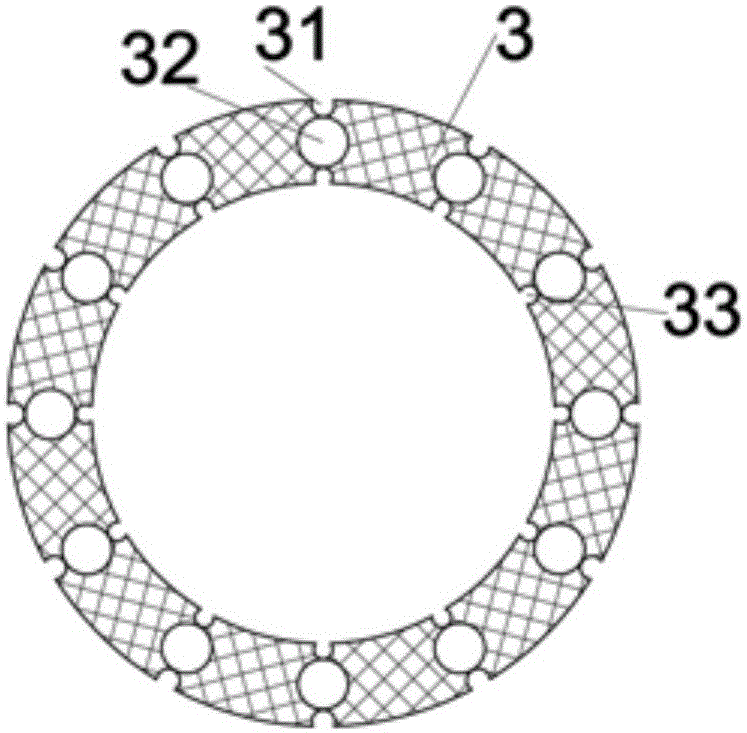

[0038] reference Figure 1 to Figure 7 ,Such as Figure 1 to Figure 3 The illustrated suspension ring structure for a shock absorber includes a pierced earring 1, which is connected to a shock absorbing cylinder 9, and a first floating sleeve 2 is provided in the pierced earring 1, and a first floating sleeve 2 is provided in the first floating sleeve 2. Two floating sleeves 3, the second floating sleeve 3 is provided with an inner sleeve 4, wherein the first floating sleeve 2 includes a number of supporting ribs 7, the number of supporting ribs 7 is 12, and the outer side of the second floating sleeve 3 is evenly distributed A number of outer grooves 31, a number of inner grooves 33 are evenly distributed inside the second floating sleeve 3, a floating sleeve hole 32 is provided between each outer groove 31 and the inner groove 33, and 32 outer grooves 31, inner grooves 33 and 32 floating sleeve holes The number is 12, the inner groove 33 and the outer groove 31 are equipped w...

Embodiment 2

[0044] reference Figure 1 to Figure 7 ,Such as figure 1 with figure 2 A suspension ring structure for a shock absorber is shown, which includes a dangling earring 1, a first floating sleeve 2, a second floating sleeve 3, an inner sleeve 4, and a plurality of buffer sleeves 6. The hanging earring 1 is fixedly connected to the absorber Below the vibrating cylinder 9, the earring 1 has a central axis 8, the wall thickness of the earring 1 is 4mm-8mm, the first floating sleeve 2 is set in the inner hole of the earring 1, and the second floating sleeve 3 is set in In the inner hole of the first floating sleeve 2, the inner sleeve 4 is sleeved in the inner hole of the second floating sleeve 3, the buffer sleeve 6 is embedded in the floating sleeve hole 32 of the second floating sleeve 3, and the buffer sleeve 6 has a buffer cavity 61. A buffer rod 62 is provided in the buffer cavity 61, and the buffer rod 62 mainly plays a role of buffering and dispersing stress.

[0045] Such as fi...

Embodiment 3

[0054] reference Figure 1 to Figure 7 ,Such as figure 1 with figure 2 A suspension ring structure for a shock absorber is shown, which includes a dangling earring 1, a first floating sleeve 2, a second floating sleeve 3, an inner sleeve 4, and a plurality of buffer sleeves 6. The hanging earring 1 is fixedly connected to the absorber Below the vibrating tube 9, the earring 1 has a central axis 8, the wall thickness of the earring 1 is 4mm-6mm, the first floating sleeve 2 is set in the inner hole of the earring 1, and the second floating sleeve 3 is set in In the inner hole of the first floating sleeve 2, the inner sleeve 4 is sleeved in the inner hole of the second floating sleeve 3, the buffer sleeve 6 is embedded in the floating sleeve hole 32 of the second floating sleeve 3, and the buffer sleeve 6 has a buffer cavity 61. A buffer rod 62 is provided in the buffer cavity 61, and the buffer rod 62 mainly plays a role of buffering and dispersing stress.

[0055] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com