spoke wheel

A spoked wheel and spoke technology, applied in the field of spoked wheels, can solve the problems of sharp increase in material consumption and adverse effects of axial rigidity, and achieve the effects of simplicity, high axial rigidity and flexible structure at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

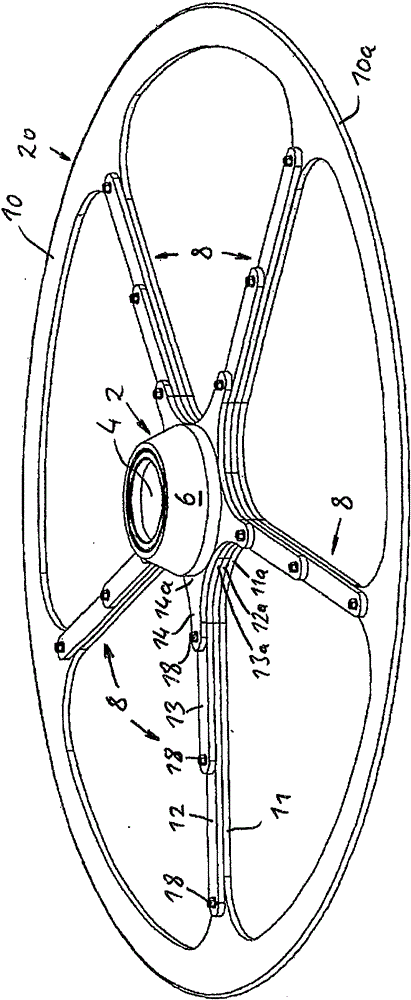

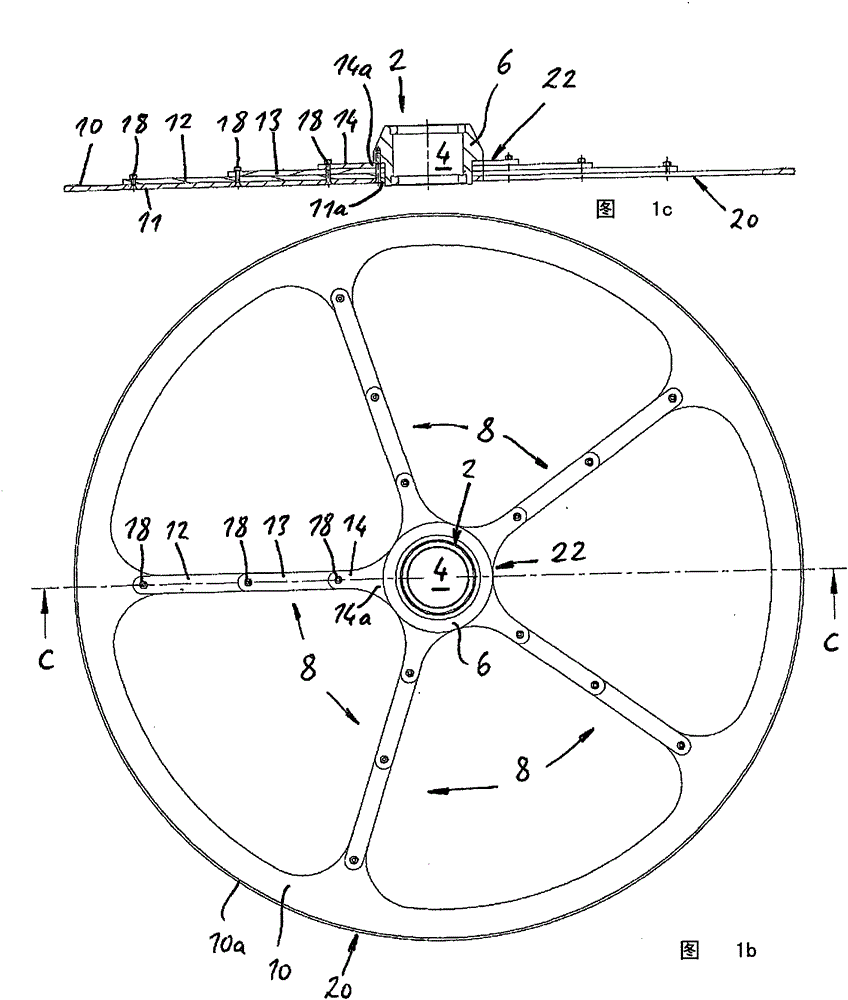

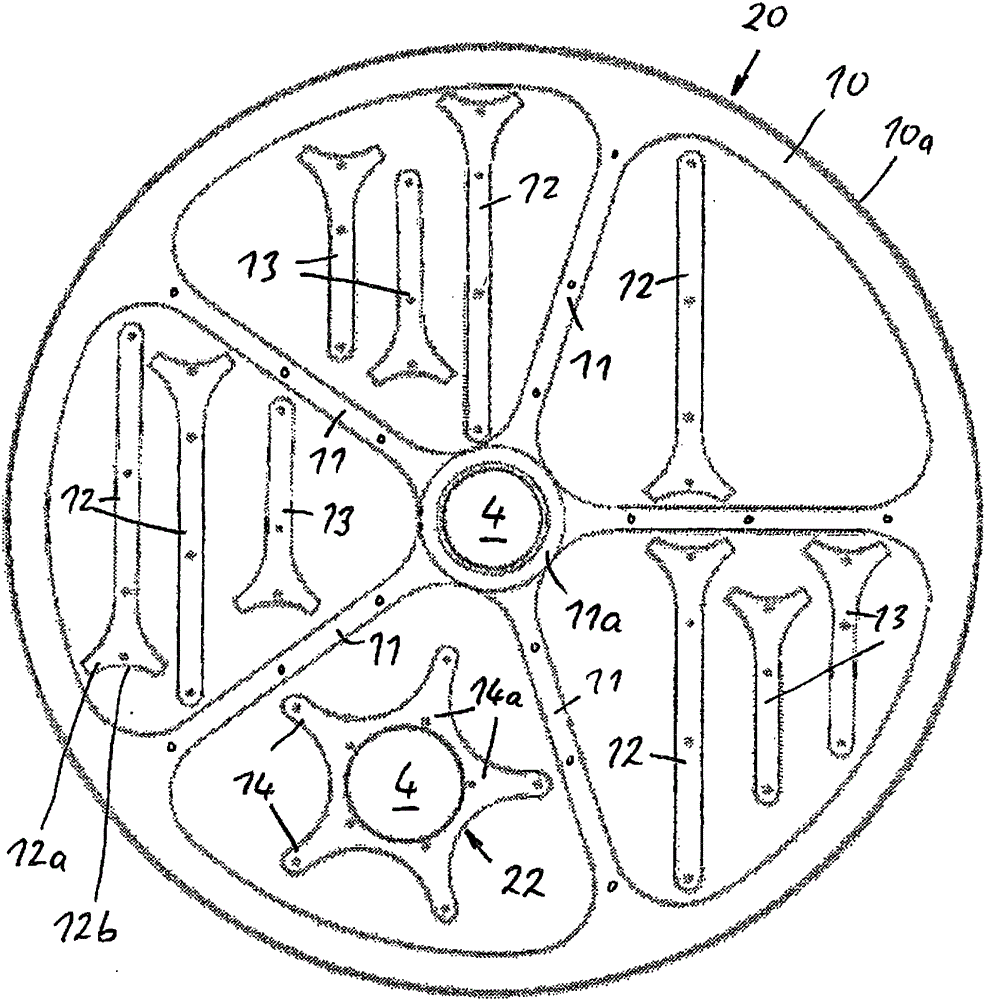

[0026] A spoked wheel according to a first embodiment of the invention is shown in FIG. 1 . The spoked wheel shown there has a hub 2 in which a central bore 4 is formed for receiving a shaft (not shown). The holes 4 are oriented at right angles to the plane of the spoked wheel, wherein the center axis (not shown) of the hole 4 coincides with the likewise not shown axis of rotation of the spoked wheel, so that the spoked wheel can be received around in the hole 4 (in the drawing). not shown) axis or axis of rotation. Furthermore, the bore 4 is delimited in the exemplary embodiment shown by a bushing 6 which is a constituent part of the hub 2 .

[0027] The spoked wheel has a plurality of spokes 8 which, in the exemplary embodiment shown, are oriented radially outward from the hub 2 and are arranged equidistant from one another. In the exemplary embodiment according to FIG. 1 , five radially oriented spokes 8 are provided. Furthermore, the spoked wheel has an annular rim 10 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com