Even heating system for liquid biochemical reaction

A biochemical reaction and uniform heating technology, applied in fluid heaters, water heaters, lighting and heating equipment, etc., can solve the problems of difficult to achieve uniform heating, complex liquid heating structure, etc., achieve simple structure, high heating uniformity, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

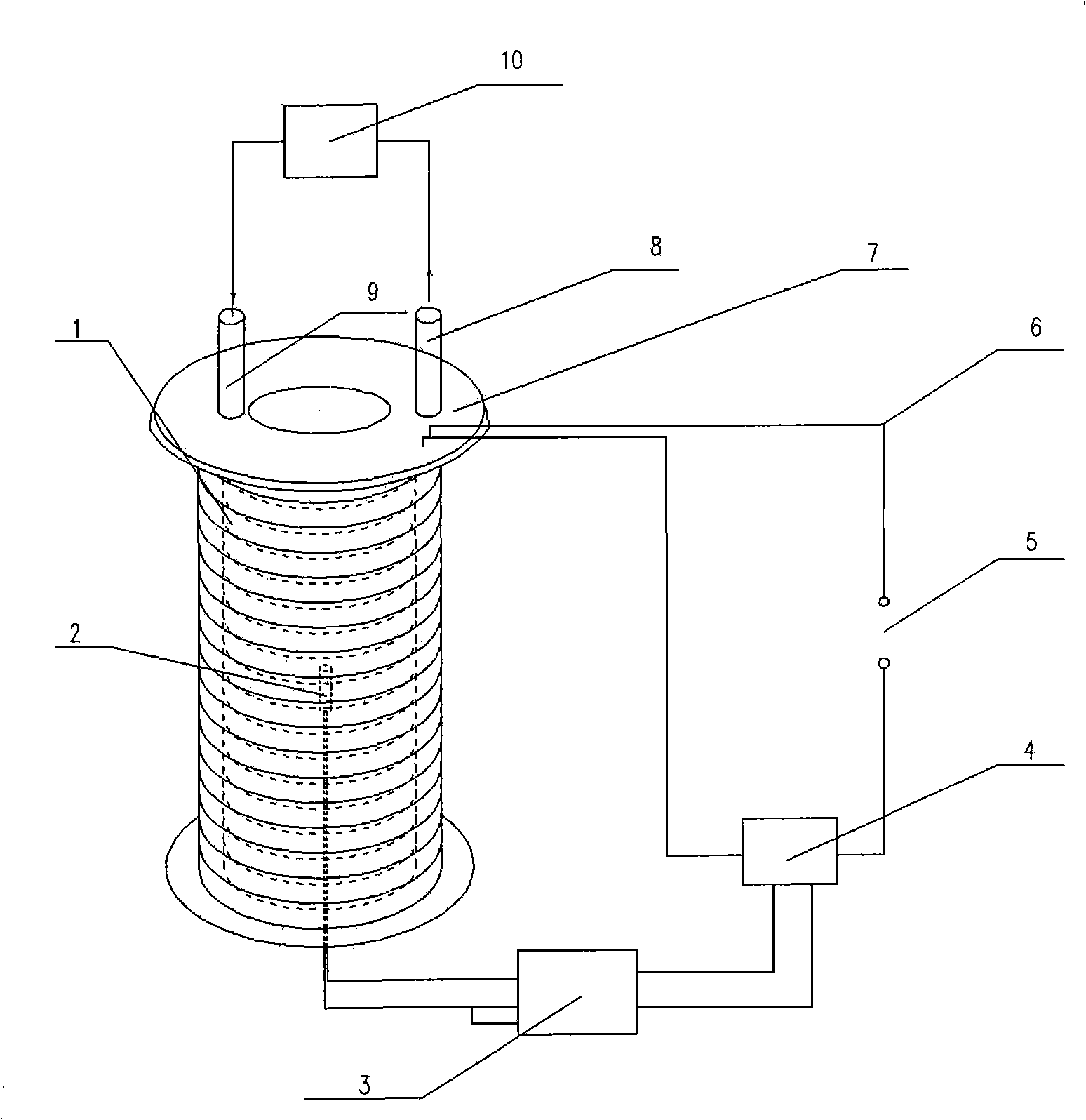

[0018] As shown in Figure 1, the uniform heating system for liquid biochemical reactions of the present invention includes a heating tube 1, a platinum resistor 2, a bracket 7, and a control circuit.

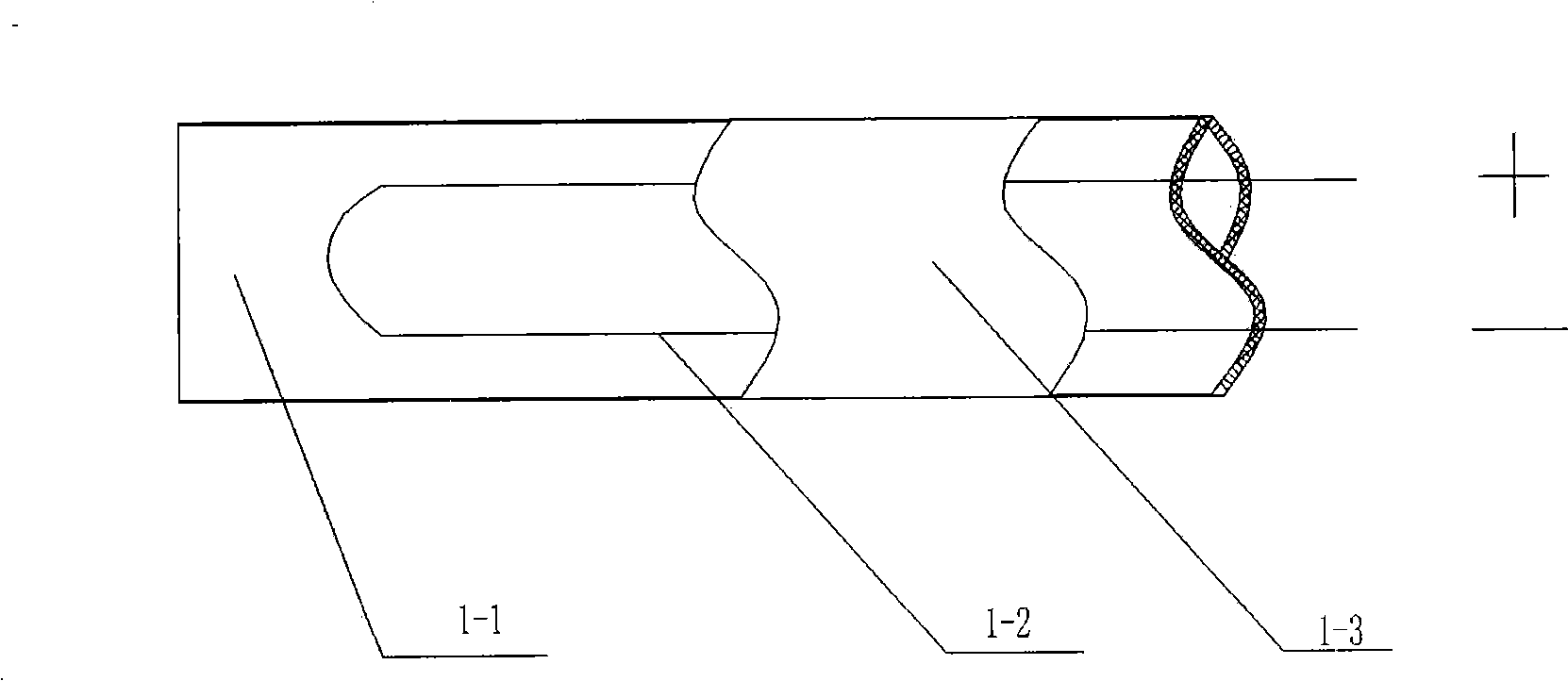

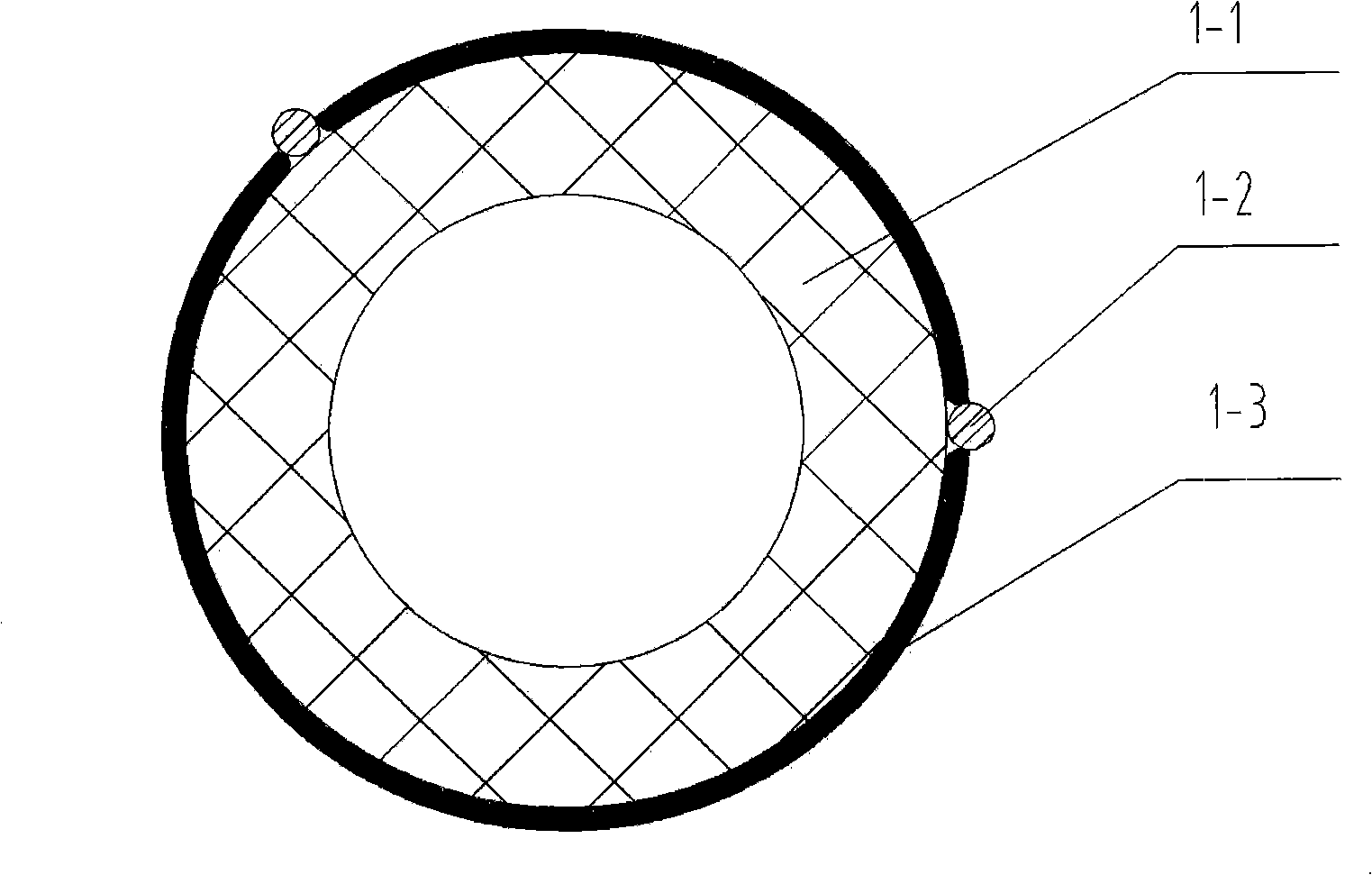

[0019] The heating tube 1 is wound on the bracket 7 in two layers, and a platinum resistor 2 is placed in the middle to measure its temperature. The upper end of the bracket 7 has a liquid inlet 8 and a liquid outlet 9 of the heating tube 1, and the liquid inlet 8 and the liquid outlet 9 is connected with the peristaltic pump 10, and the two liquids are mixed evenly and slowly under the action of the peristaltic pump 10, flowing in from the liquid inlet 8 of the heating tube, and flowing out from the liquid outlet 9.

[0020] The control circuit is composed of a temperature control instrument 3, a power adjustment module 4, a regulated power supply 5 and a wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com