Transmission module

A transmission module and moving axis technology, applied in optics, instruments, furnaces, etc., can solve problems such as substrate fragmentation, retention, and impact on transmission accuracy, and achieve the effect of improving accuracy and reducing the number of adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

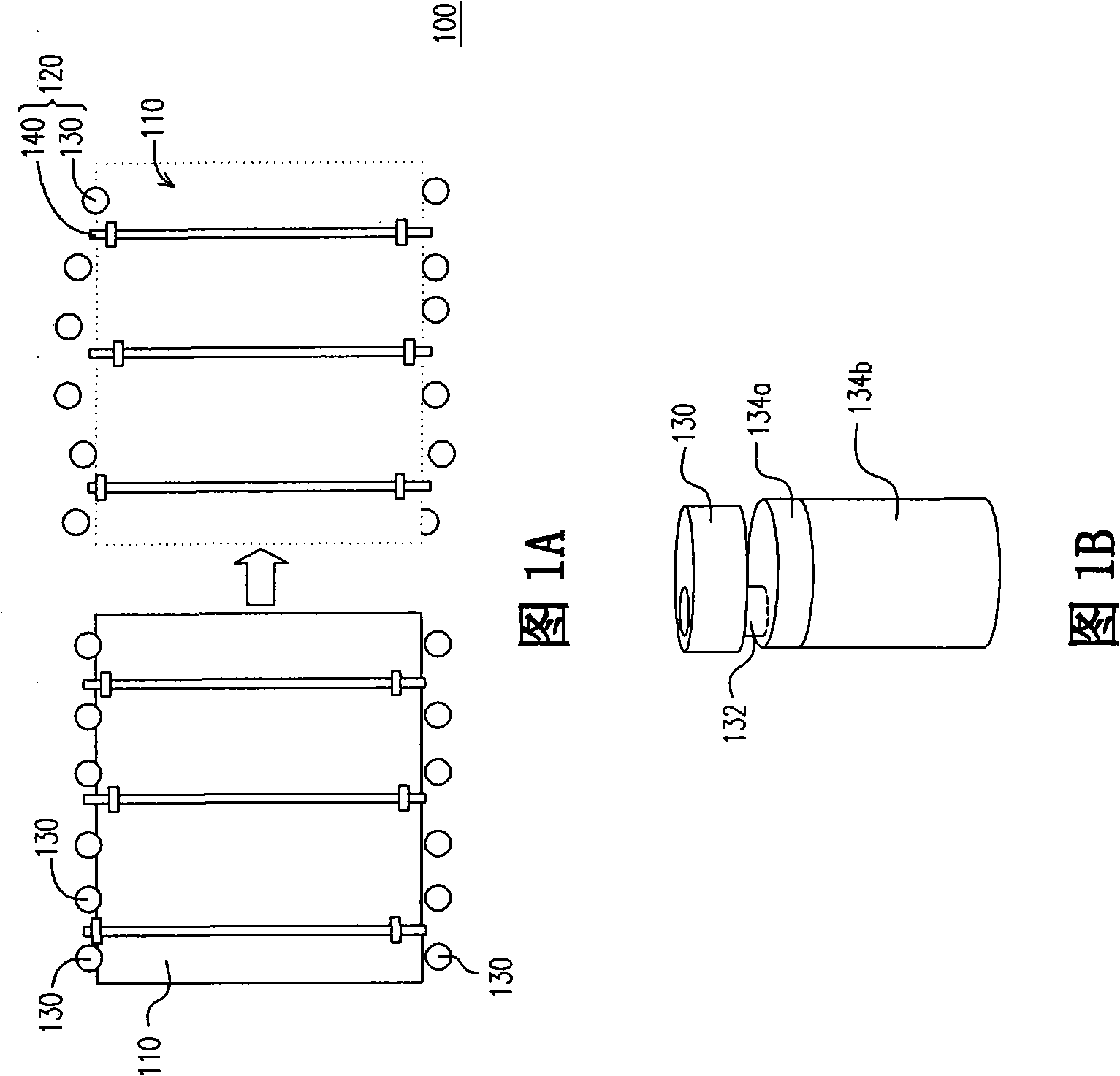

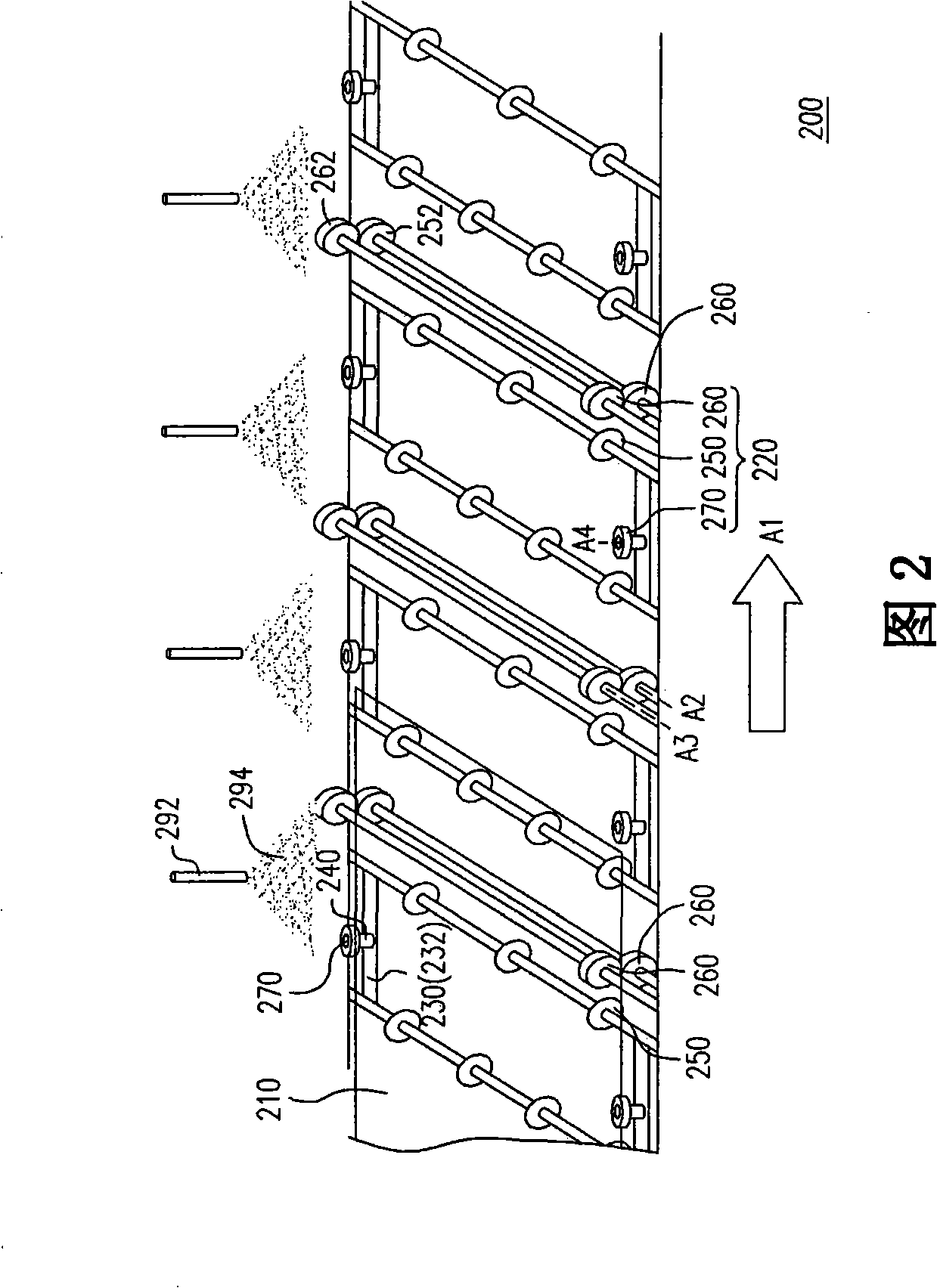

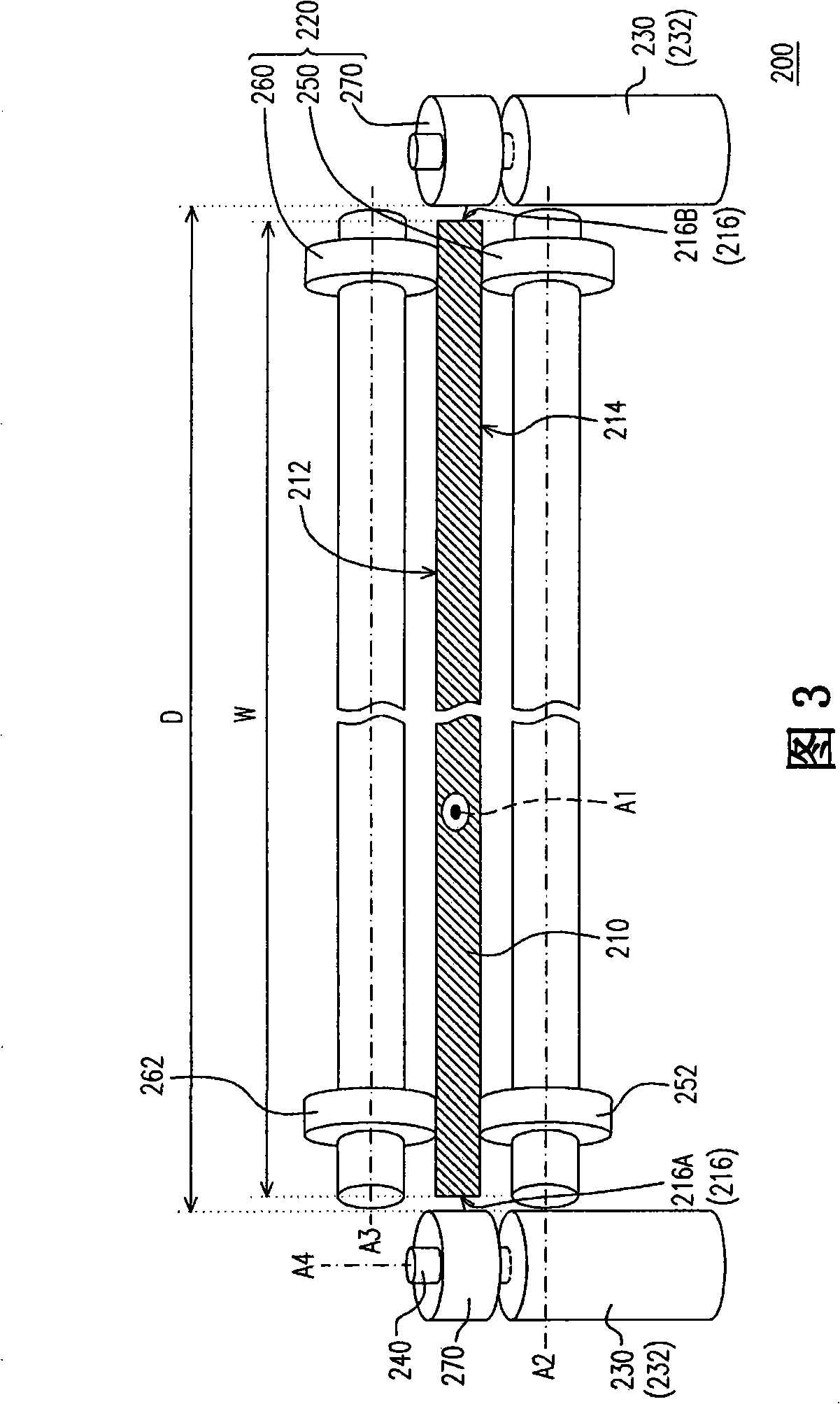

[0069] Fig. 2 is a schematic partial top view of a transmission module of the present invention. Referring to FIG. 2 , the transmission module 200 is suitable for transferring a substrate 210 such that the substrate 210 moves along the moving axis A1 , wherein the substrate 210 may be a glass substrate, a wafer or other objects to be processed. The substrate 210 has an upper surface 212 , a lower surface 214 opposite to the upper surface 212 , and two opposite sides 216 (shown in FIG. 3 ) connecting the upper surface 212 and the lower surface 214 . As shown in FIG. 2 , the transmission module 200 is mainly composed of a transmission device 220 , a fixing seat 230 and a plurality of penetrating parts 240 , wherein the material of the fixing seat 230 is, for example, stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com