Cutting tool design method for removing cross hole bur and cutting tool

A cutting tool design and cross-hole technology, which is applied in computer control, general control systems, instruments, etc., can solve the problem of long time-consuming program processing and achieve the effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

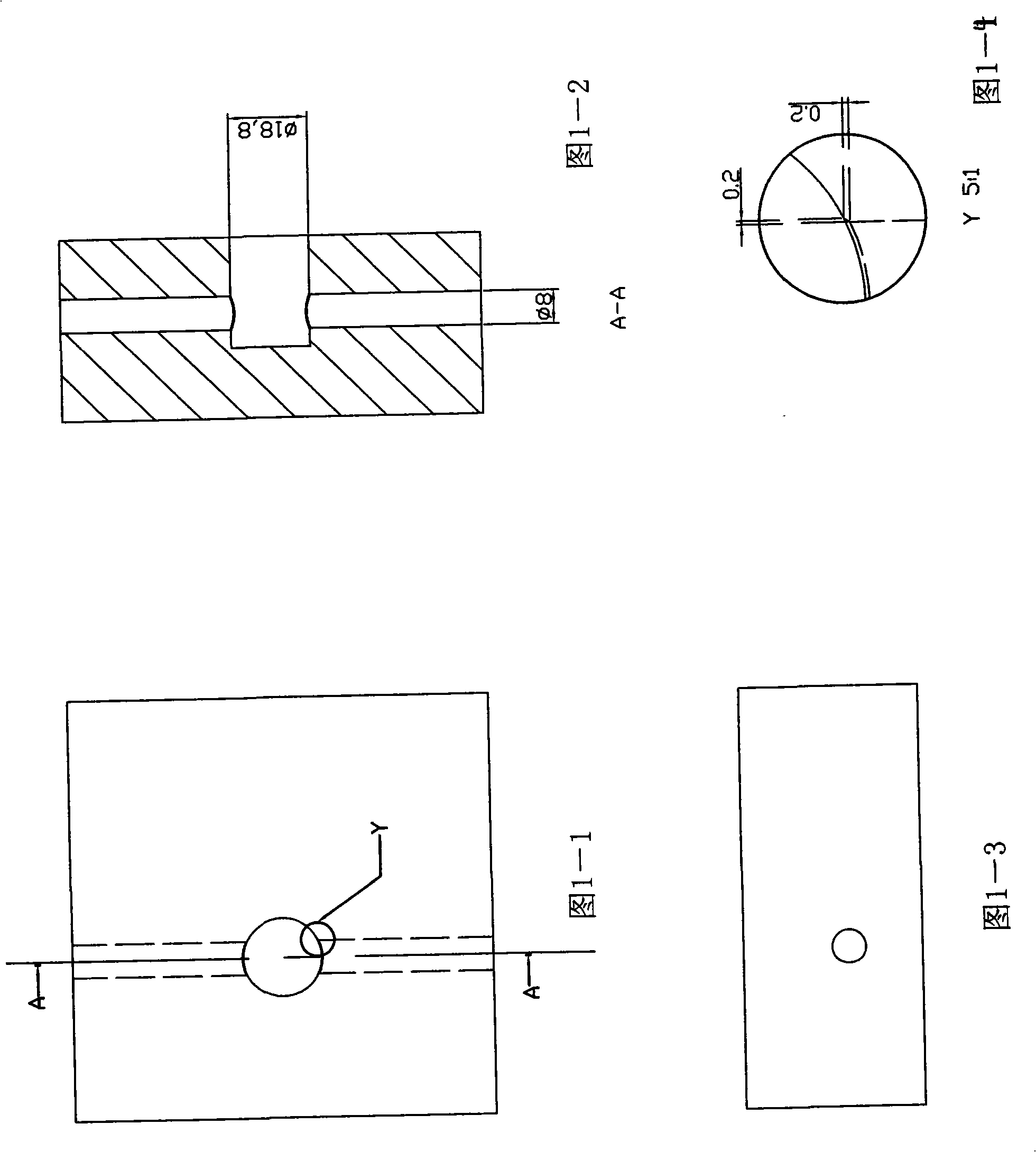

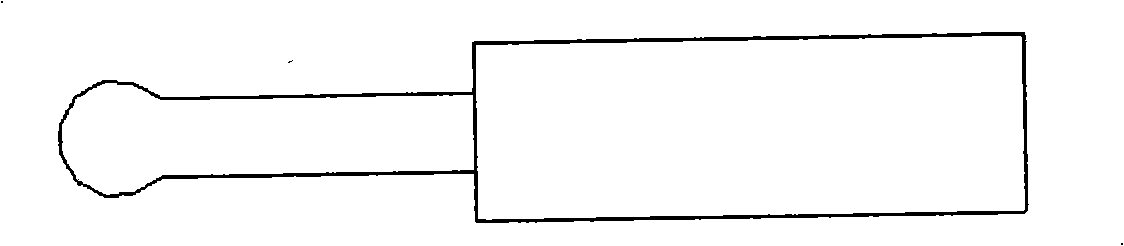

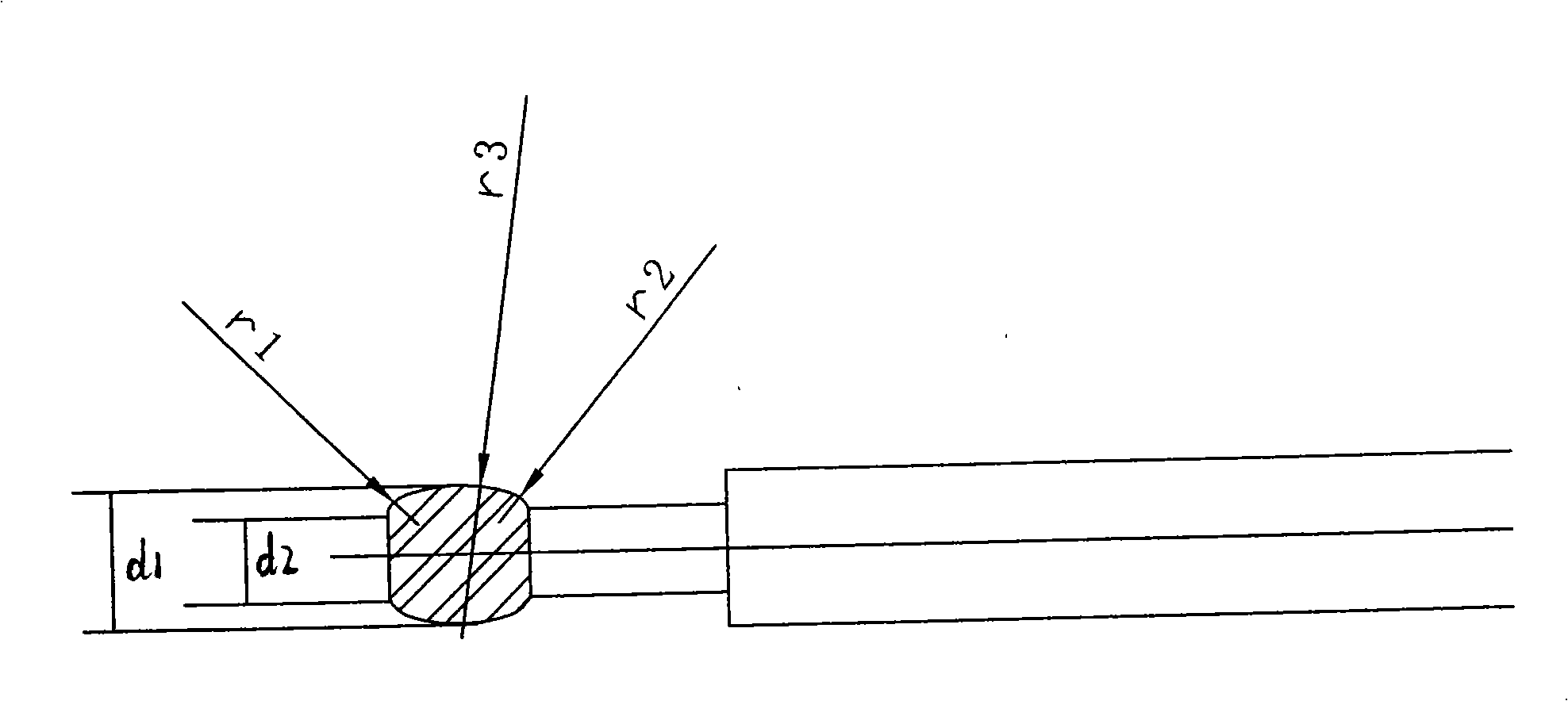

[0047] The present invention designs a tool with a special shape through proe three-dimensional software modeling, enters from hole B, takes a straight line and circular interpolation, and chamfers the intersecting line of the two holes by 0.2mm to ensure the removal of burrs. The following are φ8.0 and φ18. 8, the program of cross hole machining is as follows:

[0048] 04117

[0049] G90G00X4.0Y-0.6S7000M07M08

[0050] Z-23.26

[0051] G01X5.0X4.95F800

[0052] G03X5.08X5.03Y-0.12R1.5F800

[0053] G00X0Y-0.6

[0054] G00X-4.0Y0.6

[0055] G01X-4.95F800

[0056] G02X-5.08X-5.03Y0.12R1.5

[0057] G00Y0.6X0

[0058] X0Y0

[0059] Z32.0

[0060] M99

[0061] The tool shape of the linear interpolation used by the present invention and the coordinates of the written ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com