Method for producing paper sheet material

A manufacturing method and board technology, which is applied in the field of paper board manufacturing, can solve the problems of paper boards such as limited strength, durability, and fear of water, and achieve good moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a further understanding and understanding of the purpose, features and effects of the present invention, the following details are as follows in conjunction with the accompanying drawings:

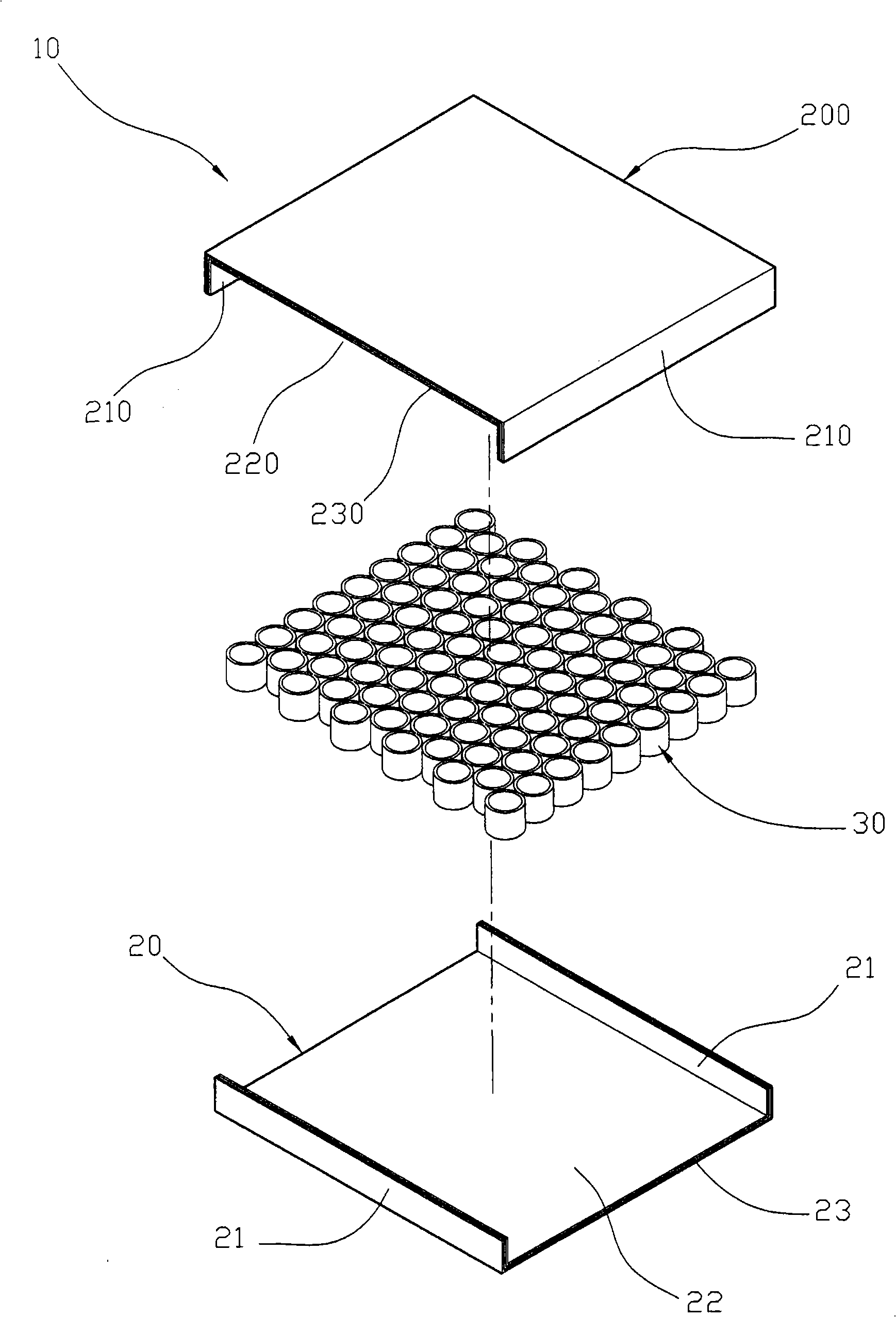

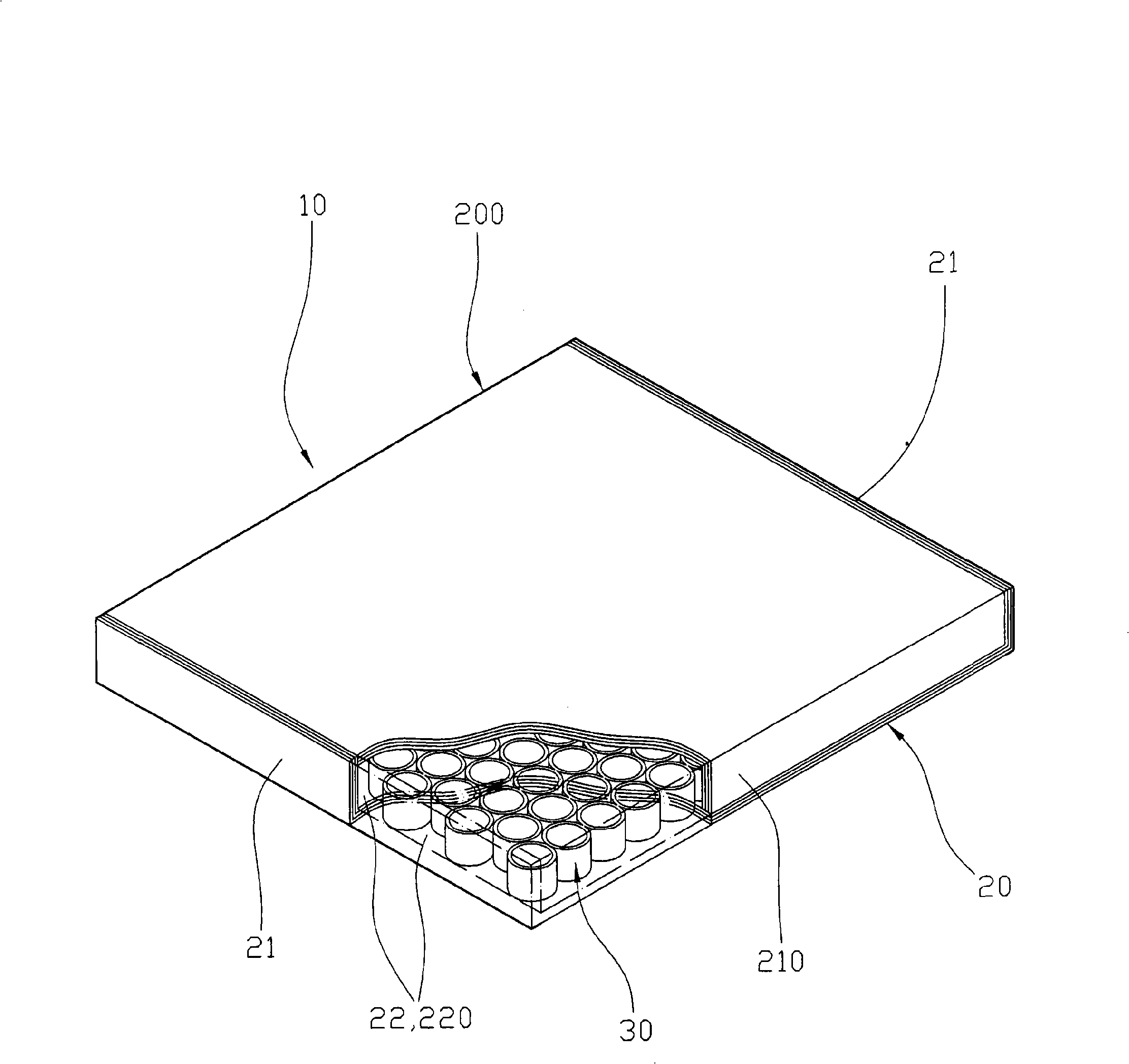

[0027] Please cooperate first figure 1 , 2 As shown, the cardboard material 10 is composed of two staggered shell-shaped cover plates 20, 200 and a plurality of paper tubes 30 arranged and combined. The shell-shaped cover plates 20, 200 can be folded at both ends of the cardboard into an upward limit position. Edges 21, 210 are formed so that a bearing groove 22, 220 is formed inside, and the paper material 23, 230 used for the shell-shaped cover plate 20, 200 can be formed by stacking several layers. The paper tube 30 is located on the shell-shaped cover plate. In the holding groove 22,220 of 20,200, draw close to, fill up with vertical, and each paper tube 30 is mutually glued and set.

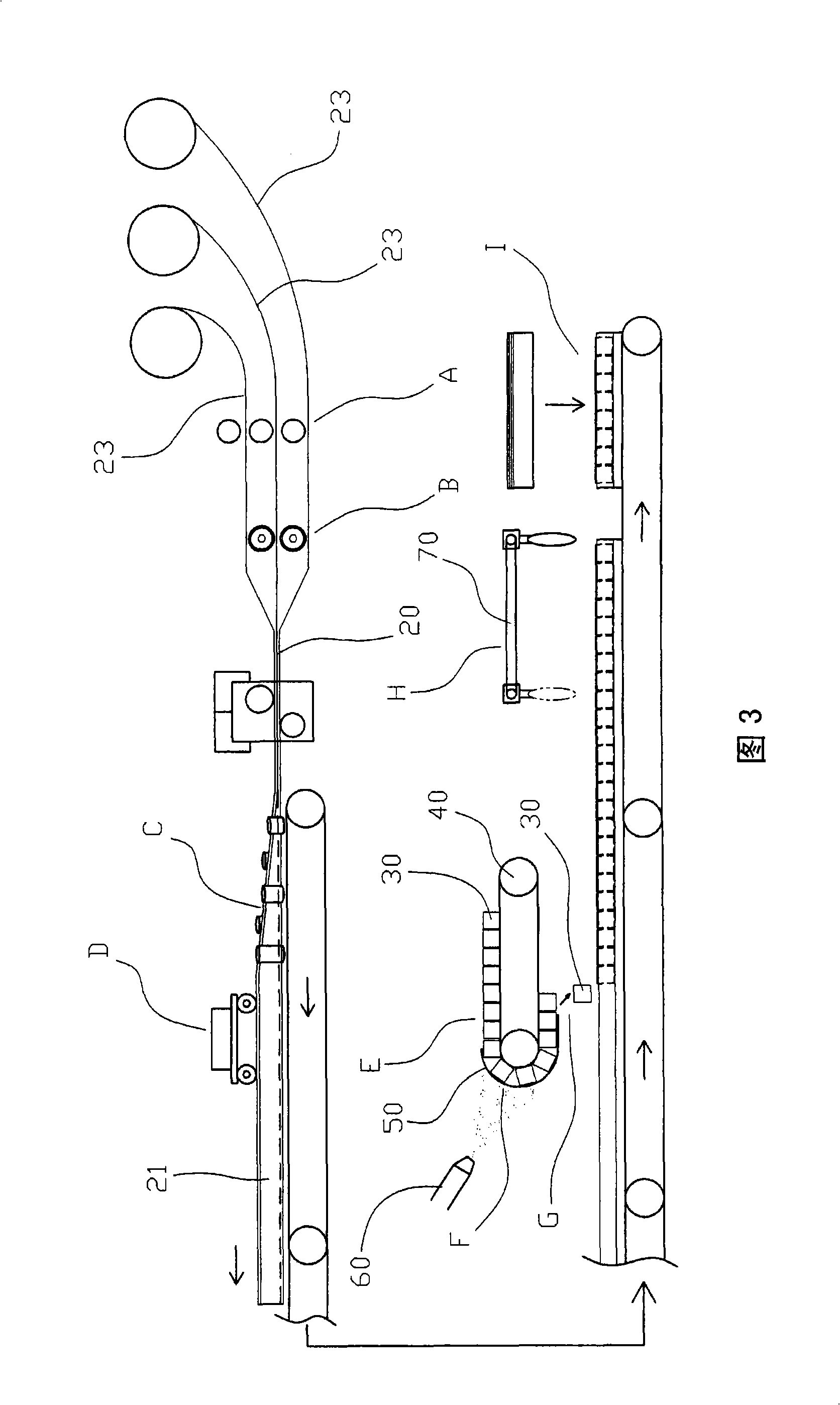

[0028] The processing and forming of its cardboard material 10 is shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com