Whirler crane

A crane and slewing technology, applied in the directions of crane, transportation and packaging, can solve the problem of inconvenient use of the crane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

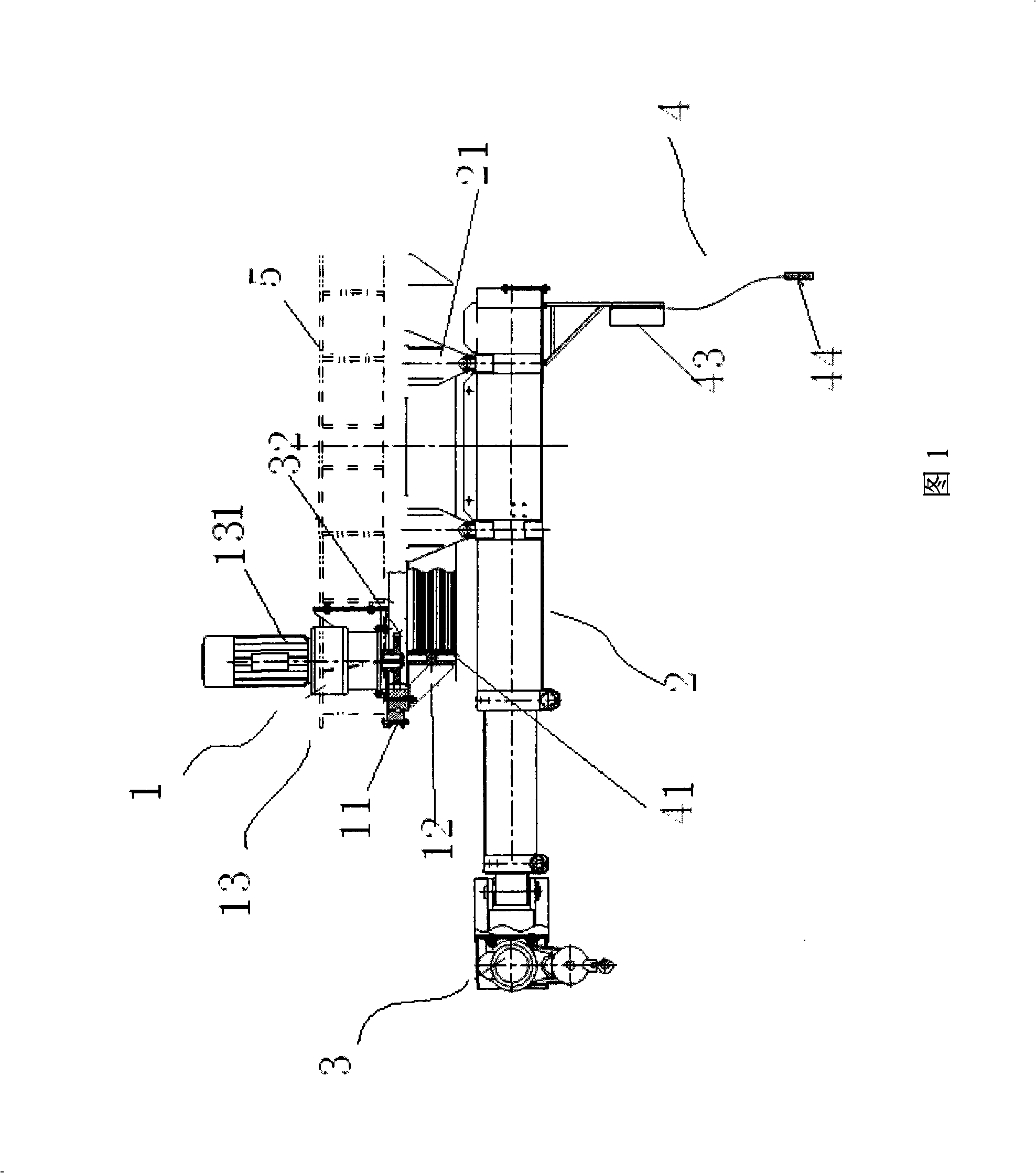

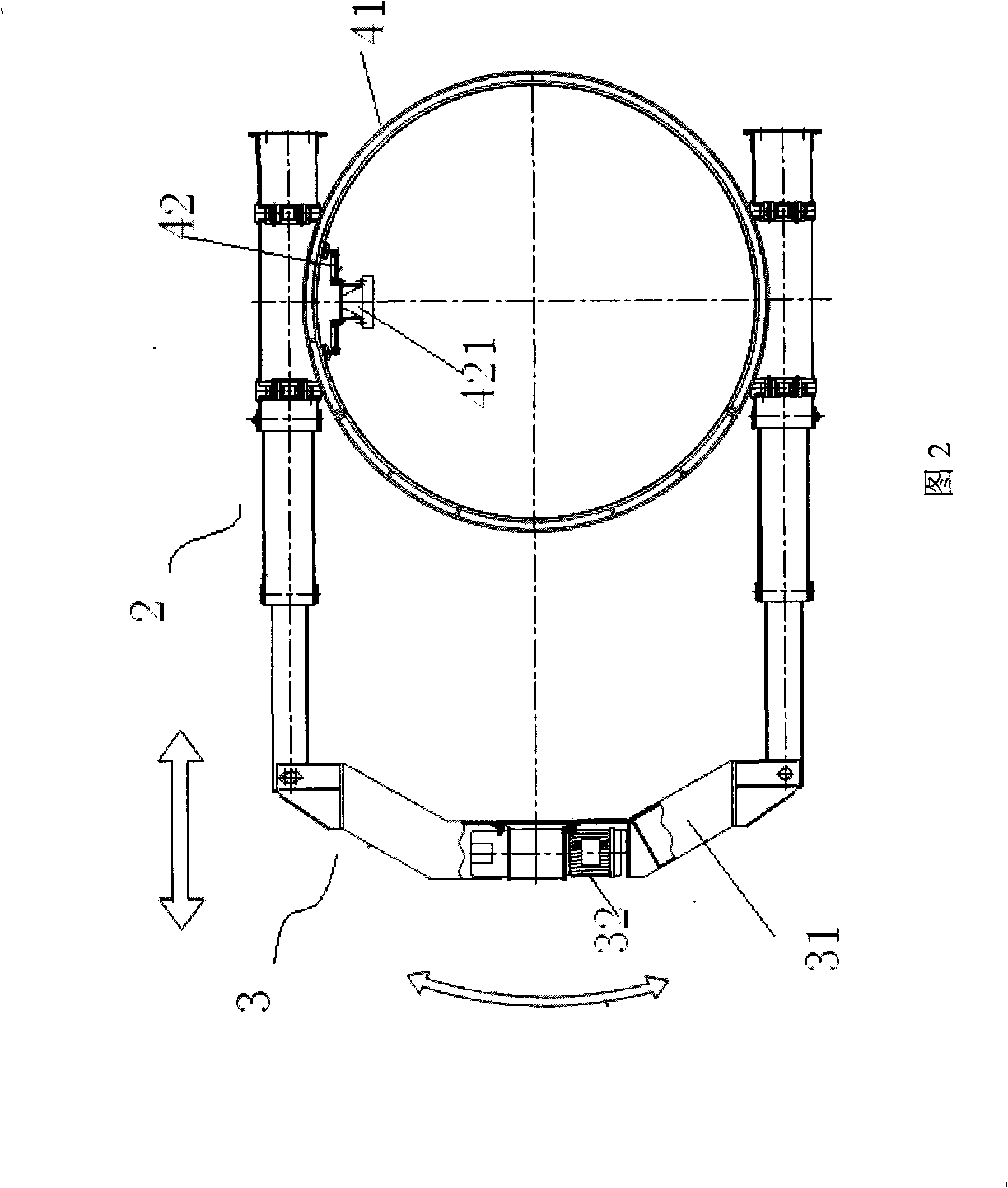

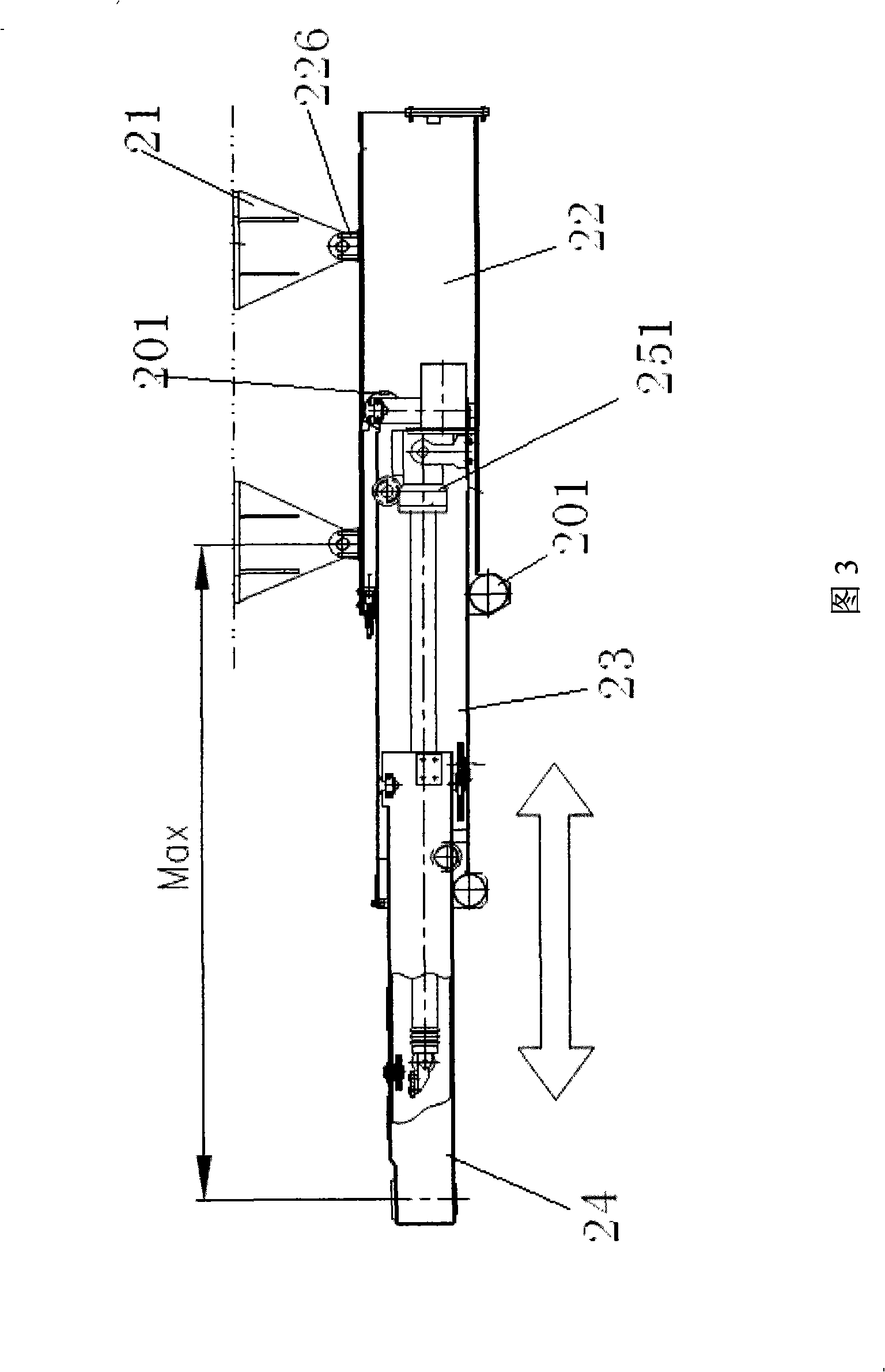

[0027] A slewing crane mainly includes: a slewing mechanism 1 , a telescoping system 2 , a lifting system 3 , and a conductive and control system 4 .

[0028] Wherein, the rotary device 1 mainly includes a rotary support 11 , a turntable 12 and a rotary drive device 13 . Wherein the slewing support 11 includes an inner ring and an outer ring, which are installed horizontally, the outer ring is connected with the upper fixed steel frame of the factory building through bolts, and the inner ring is connected with the rotating disk 12 . The rotary driving device 13 is composed of a cycloidal pinwheel deceleration motor 131 and a driving gear 132. The driving device 13 is fixedly installed on the fixed steel frame of the workshop, and the gear 132 is mounted on the output shaft of the deceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com