Installation of cured in place liners with air and flow-through steam to cure

A technology of lining and steam, applied in the direction of pipe elements, mechanical equipment, pipes/pipe joints/fittings, etc., which can solve the problems of limiting the length of air turning, increasing energy and labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

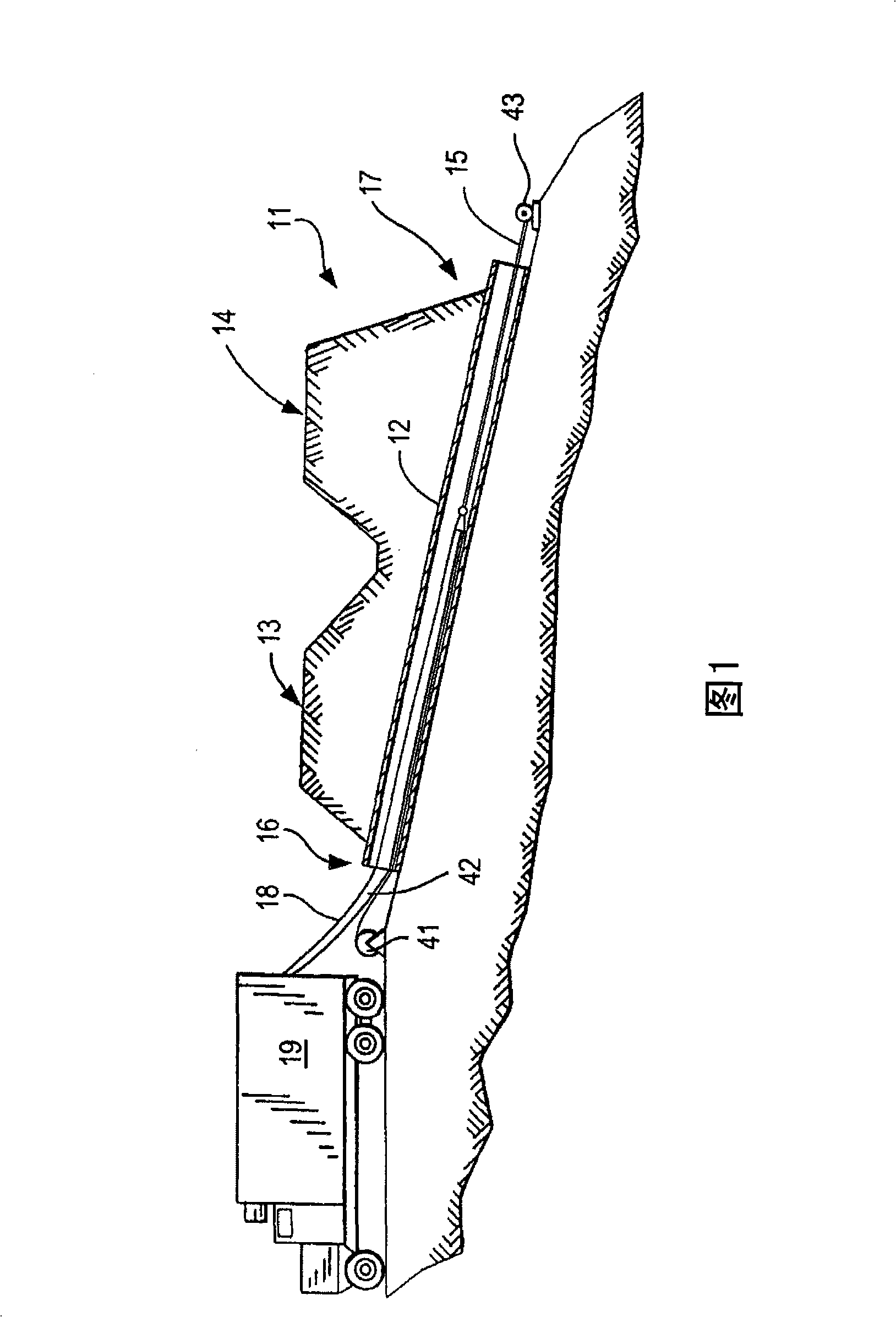

[0047] FIG. 1 shows a typical highway culvert 11 with existing passageway 12 that traverses beneath highways 13 and 14 . FIG. 1 shows an upper opening 16 and a lower opening 17 . At the job site, moderately refrigerated trucks 19 provide the resin-impregnated liner which is pulled in from the upper opening 16 by a winch 43 at the lower open end 17 . Liner 18 is wrapped with a polypropylene sleeve to prevent damage and control longitudinal stretch.

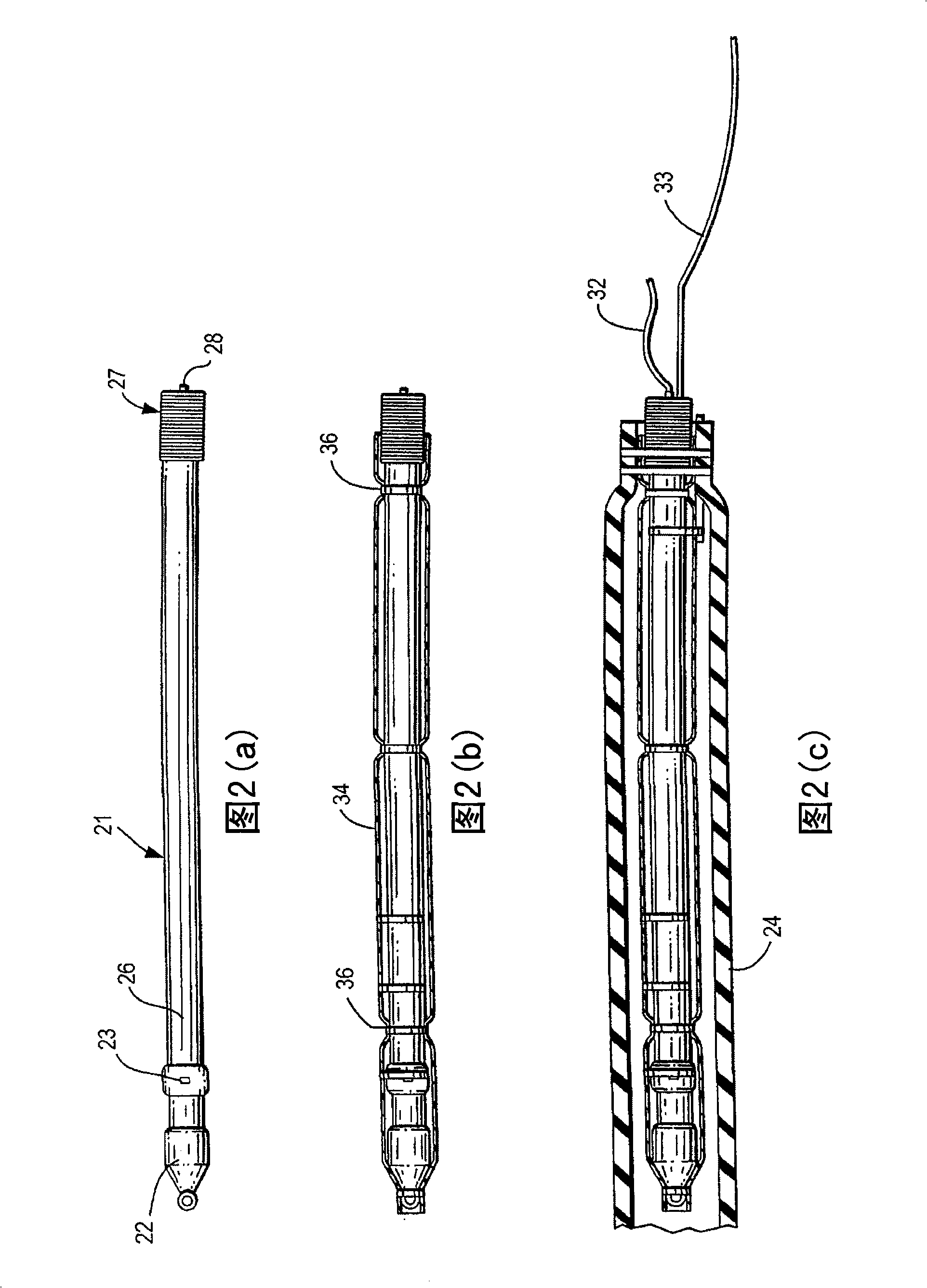

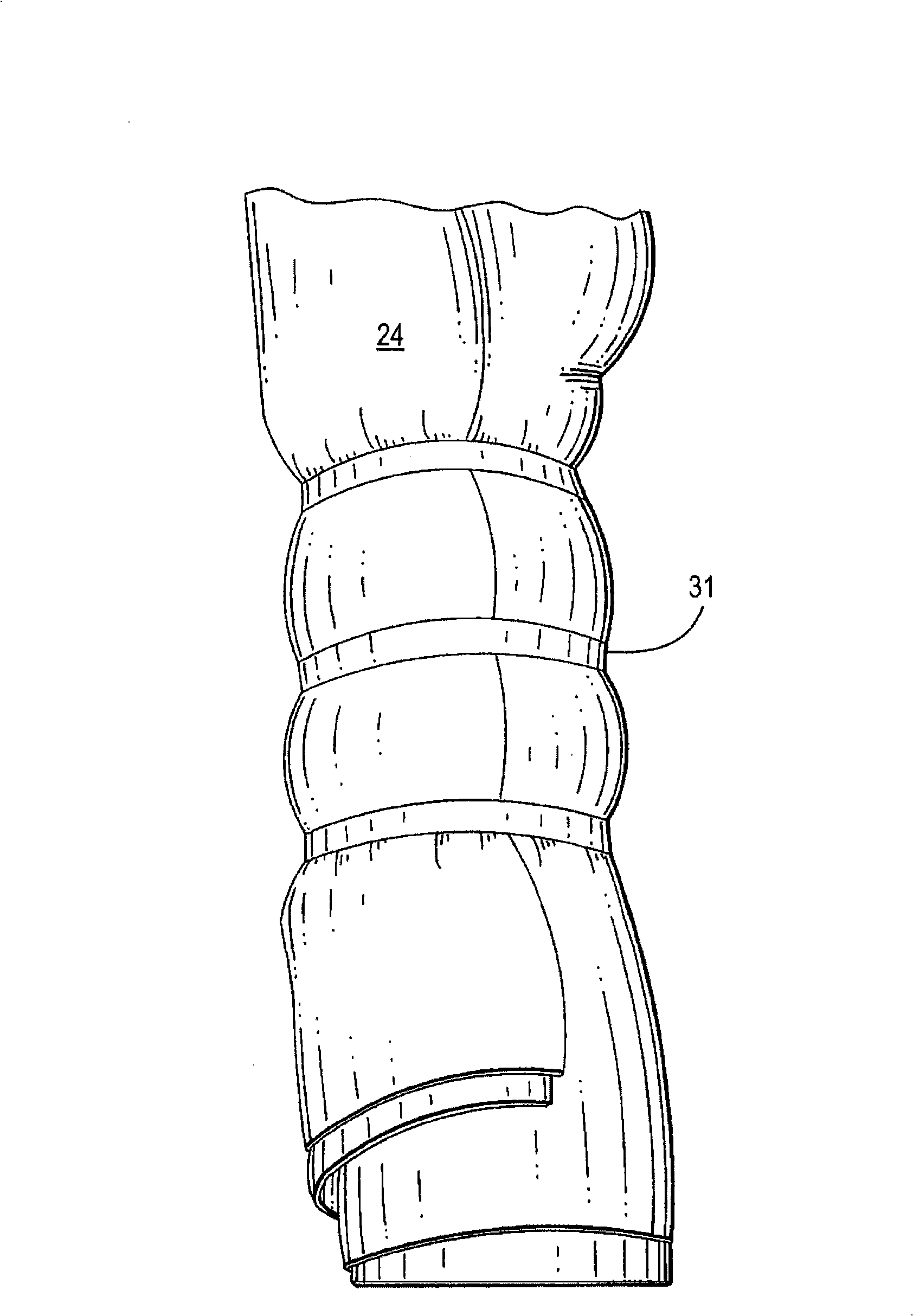

[0048] Flexible cure-in-place liners of the type known in the related art are made of at least one layer of flexible resin-impregnable material, such as a felt layer or the like with an outer impermeable polymeric film layer. The felt and membrane layers are sewn along the seam lines to form the tubular inner lining. In order to ensure the impermeability of the inner liner, a thermoplastic film in strips is placed on the seam line or a compatible extrusion material is extruded on the seam line. Such liners are disclosed in detai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com