Two-way needle control valve

A technology of through-needle and valve body, which is applied in the direction of charging system, fuel injection device, machine/engine, etc., and can solve the problems of interfering with the lifting member 106 and hindering the response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

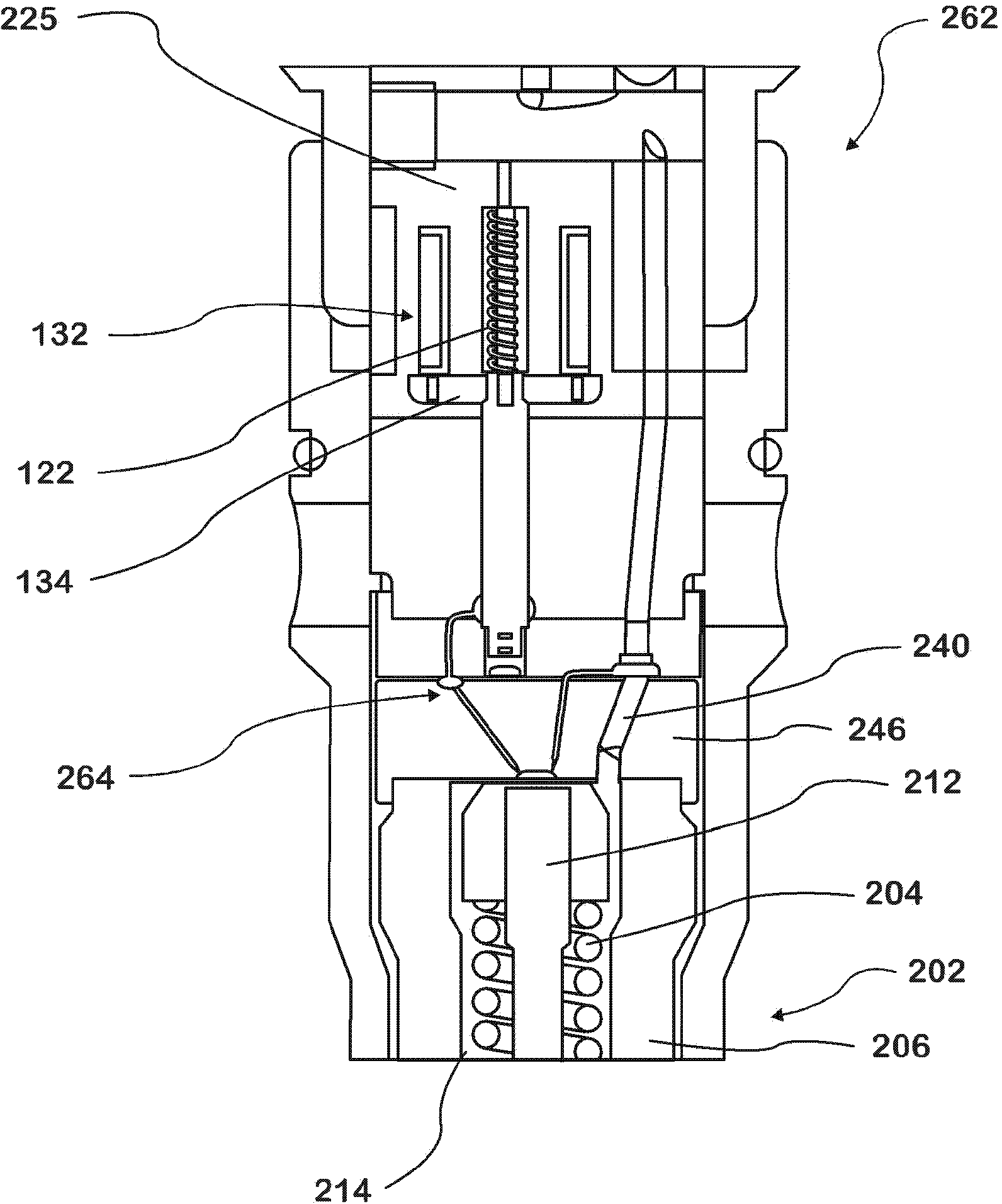

[0014] figure 2 A cross-sectional view of a portion of high pressure fuel injector 262 is shown. The high pressure fuel injector 262 generally includes a nozzle portion 202 . The nozzle portion 202 includes a spring 204 and a nozzle body 206 . The nozzle body 206 and the throttle plate 246 form a longitudinal bore that terminates within the nozzle bore at the end or bottom of the fuel injector 262 . A nozzle valve, such as a needle valve, is configured such that the needle 212 of the needle valve is slidably disposed within the longitudinal bore to move the needle between a first (closed) position and a second (open) position, the first position blocking the nozzle communication between the chamber 214 and the nozzle hole, while the second position opens communication between the nozzle chamber 214 and the nozzle hole. Spring 204 is positioned within nozzle chamber 214 and acts on needle 212 to bias needle 212 to its first (closed) position.

[0015] During operation, fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com