Equalizer bar bearing assembly

A technology for equalizers and bearings, applied in the direction of bearing components, bearings for rotational motion, bearings, etc., can solve problems such as variable internal pressure, overpressure of pin joint seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

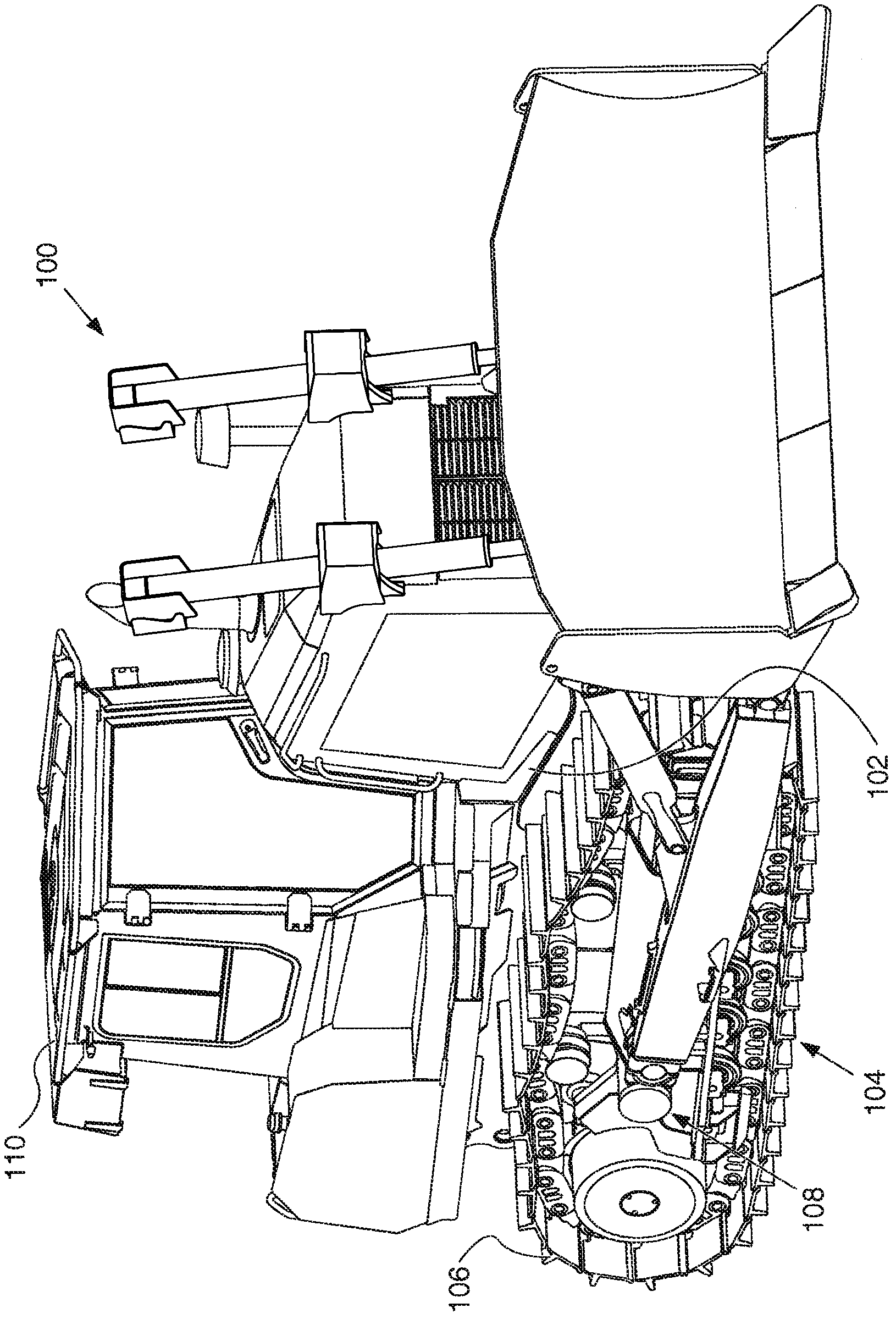

[0017] An exemplary embodiment of machine 100 is in figure 1 shown schematically. Machine 100 may be a motorized machine performing some type of operation associated with an industry such as mining, construction, farming, transportation, or any other industry known in the art. For example, machine 100 may be a track-type tractor, such as figure 1 As shown, it has a frame 102 and a tracked undercarriage 104 operably mounted to the frame 102 . The undercarriage 104 may include a pair of track chains 106 orbiting about a pair of laterally spaced track roller frames 108 .

[0018] A power source, such as an electric motor, a hydraulic motor, or an engine, may be used to actuate undercarriage 104 to move track chains 106 about track roller frame 108 to propel or move machine 100 . Track roller frame 108 may include various undercarriage 104 components, such as track or load wheels, load rollers, idler wheels, and other conventional components, that support and Guides the track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com