Lighting arrangement with semiconductor light sources on flexible printed circuits

A lighting device, flexible printing technology, applied in the direction of folded flexible circuit boards, lighting devices, lighting device parts, etc., can solve the problems of inability to automate, difficult to automate, flexibility restrictions, etc., to achieve easy automation, save positioning Pieces, the effect of robust settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] At present, headlights on automobiles mainly use halogenated or gas discharge lamps, while automotive lamps still mainly use filament lamps. More recently, however, light-emitting diodes (so-called Light Emitting Diodes, LEDs) have also been used, which are particularly advantageous due to their long service life, small external dimensions, impact resistance and low weight compared with other types of lamps.

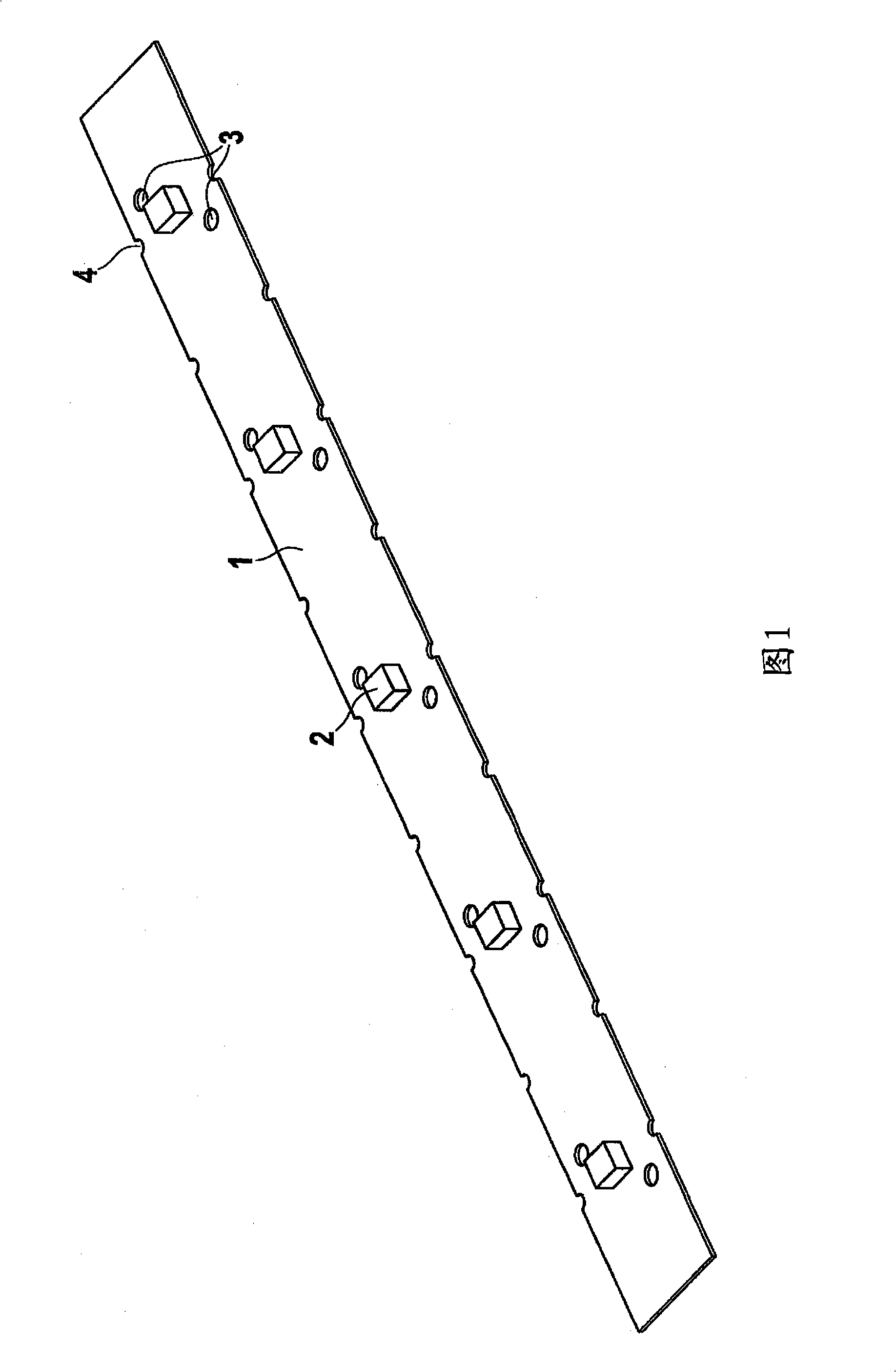

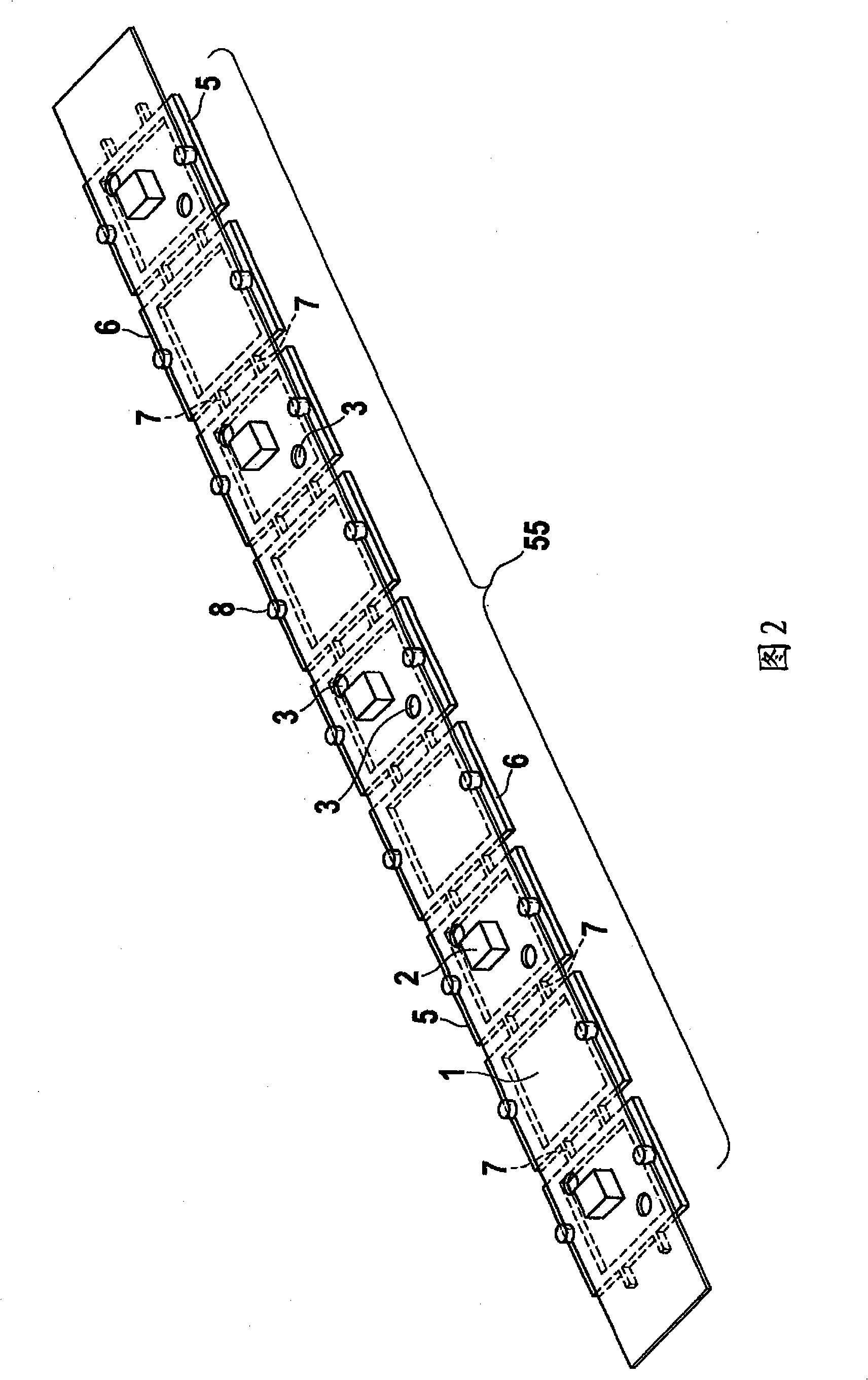

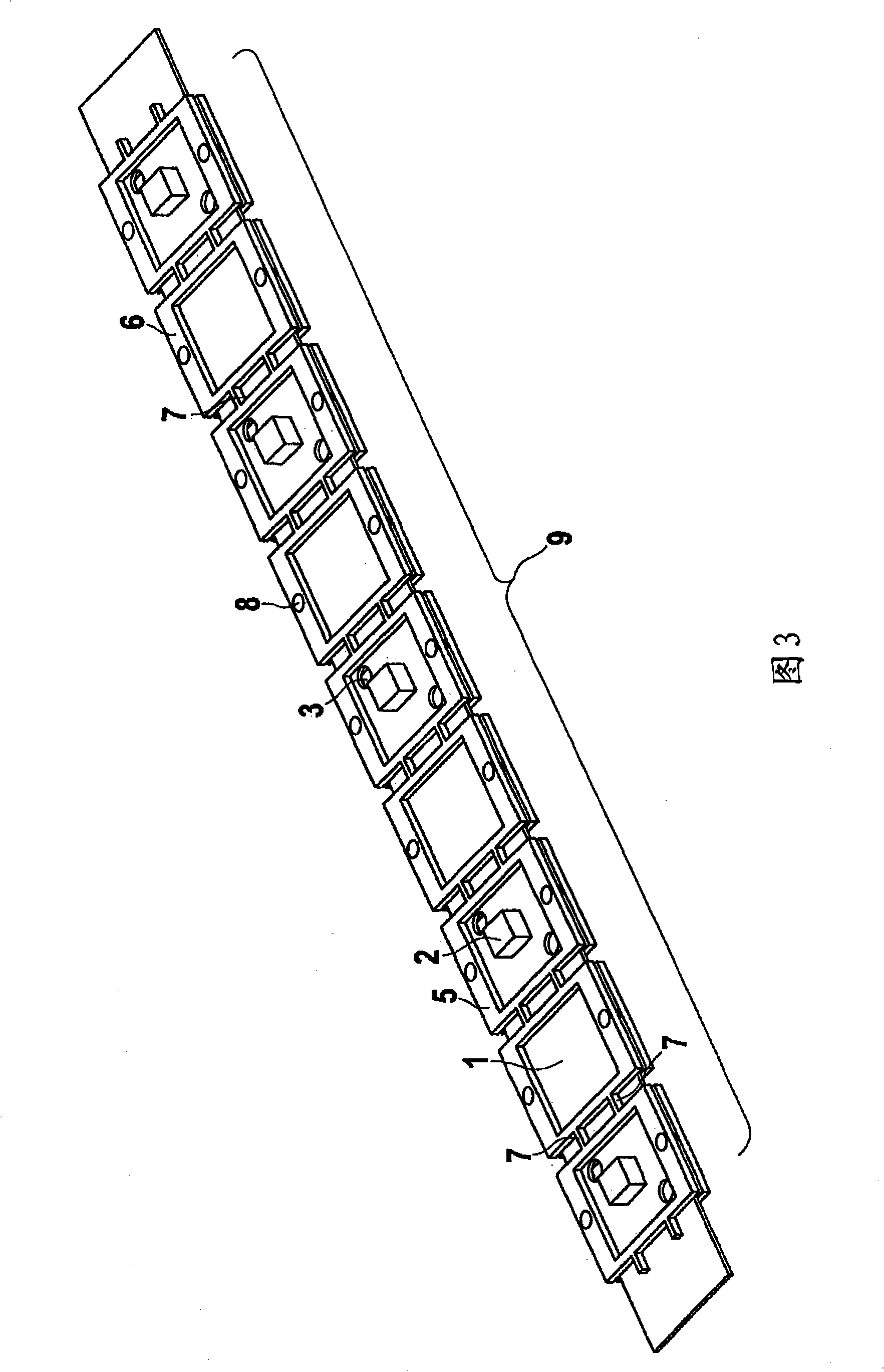

[0025] The invention relates to a lighting device, which has at least one LED, at least one cooling body and at least one condenser lens group arranged on a flexible printed circuit board (also known as a flexboard) and electrically contacted thereon. . Such a lighting device is designed, for example, as a headlight or as any desired lamp. Figure 1 shows such a flexible printed circuit board 1, which is used according to a preferred embodiment of the invention. The printed circuit board 1 is designed in the form of a strip, ie the length of the printed circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com