Infrared ray transmitting and receiving circuit unit for infrared ray touch screen

A circuit board unit, infrared technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problem that infrared emission and receiving signals cannot be transmitted to the microprocessor or its corresponding connection, and limit infrared rays Production and sales of touch products, difficulties in high-resolution touch screens, etc., to achieve the effect of improving development and design efficiency, strong consistency, and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

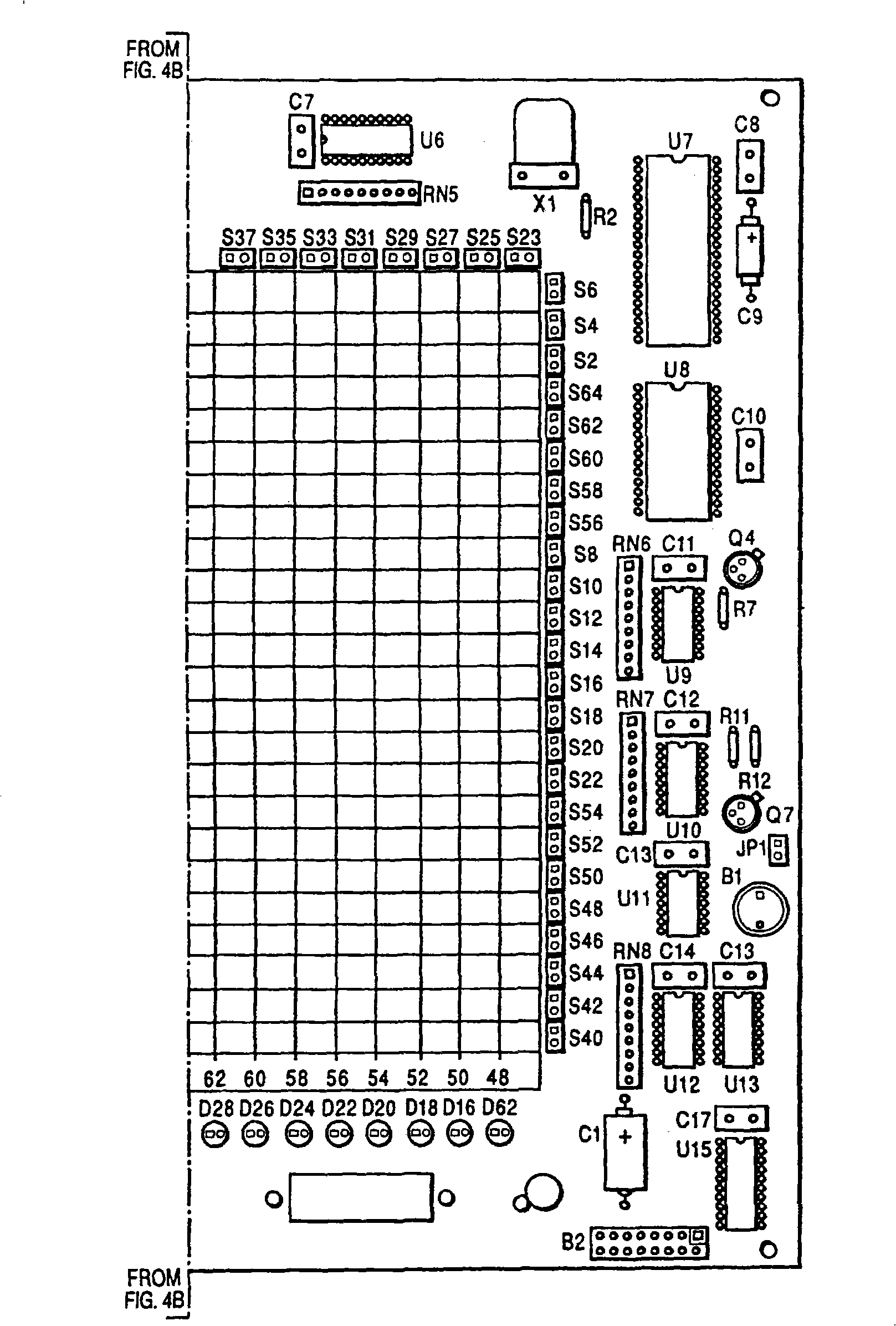

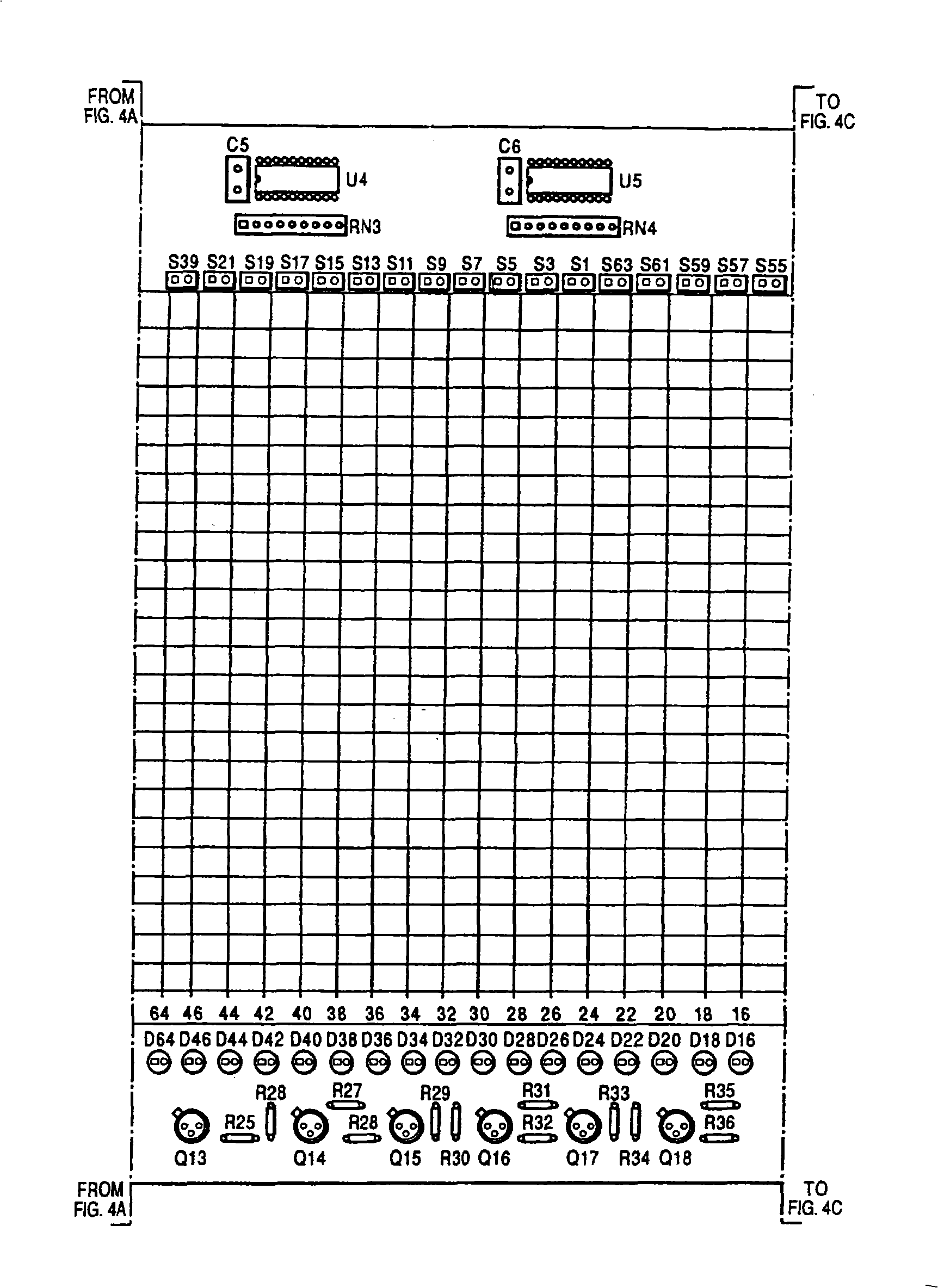

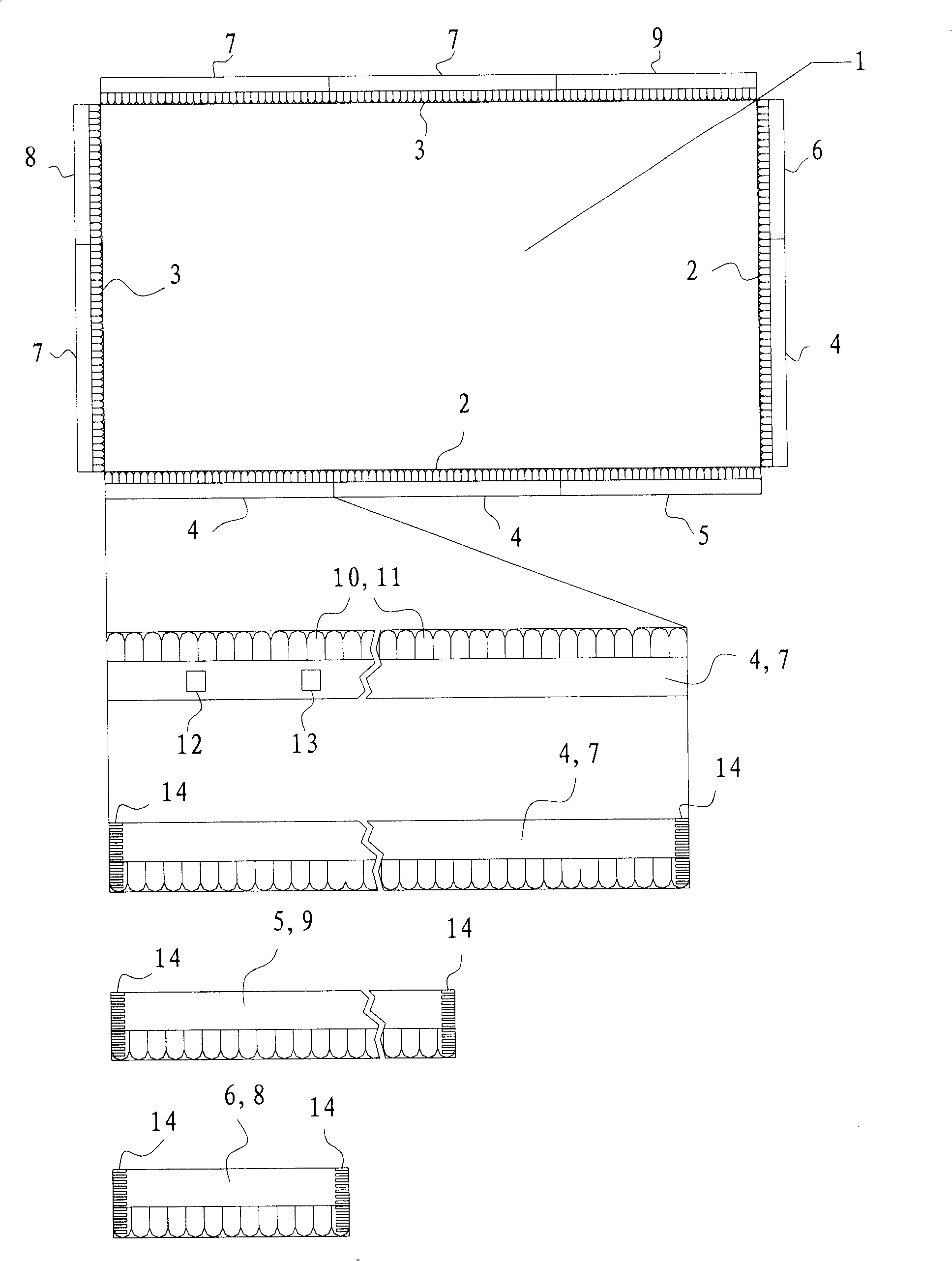

[0021] refer to image 3 , 4, 5 and 6 are an infrared touch screen 1 composed of an infrared emitting and receiving circuit board unit, and a touch screen composed of a standard emitting circuit board unit 4 and cut infrared emitting circuit boards 5 and 6 is arranged around it An infrared emitting array 2; and a receiving array 3 composed of a standard receiving circuit board unit 7 and cut receiving circuit board units 8 and 9 is arranged on the opposite side of the emitting array 2;

[0022] Each transmitting circuit board unit 4, 5, 6 comprises an infrared emitting tube 10 arranged in an array, and is provided with a power supply line 18, a grounding line 19, a clock signal line 16 and an infrared pulse signal line 17 passing through the entire transmitting circuit board unit. One end of the circuit board unit is provided with a row driver 12 and a column driver 13, and the two ends of the circuit board unit are provided with cable welding ports 14 respectively connected t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap