High on-state voltage LED integrated chip with electrostatic protection and manufacturing method thereof

A technology for electrostatic protection and integrated chips, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of inability to achieve series connection, poor high-voltage resistance, and easy short-circuiting of integrated chips, achieving low cost and occupation. The effect of small area and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

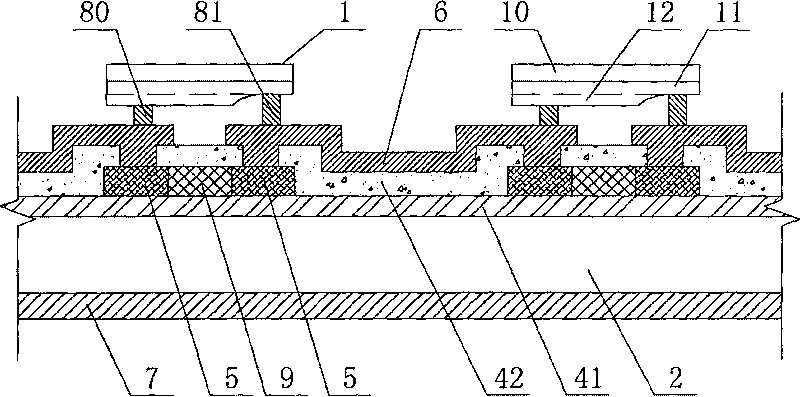

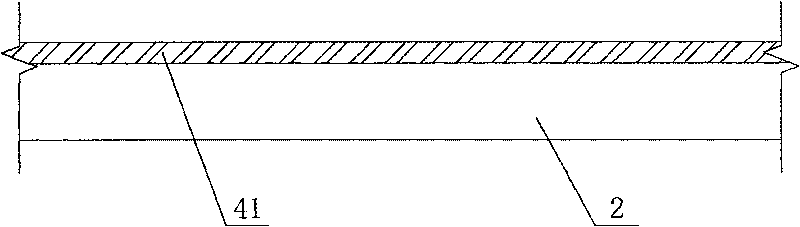

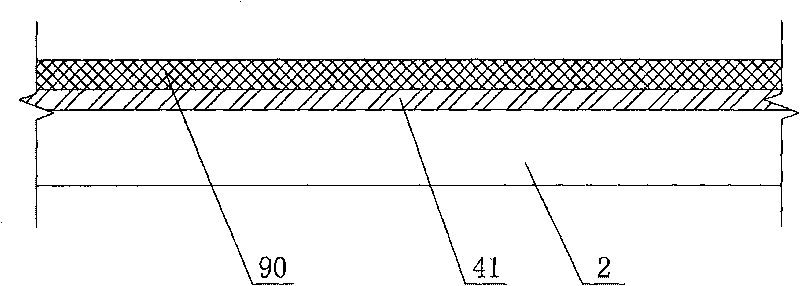

[0058] Such as figure 1 As shown, the high-on-voltage LED integrated chip with electrostatic protection of this embodiment includes several LED bare chips 1 and a silicon substrate 2. The LED bare chips 1 include sapphire (Al 2 O 3 ) A substrate 10 and a gallium nitride (GaN) N-type epitaxial layer 11 and a P-type epitaxial layer 12. Of course, the substrate 10 may also be a substrate made of other materials such as silicon carbide (SiC). The silicon substrate 2 is a P-type silicon substrate. A thermally conductive insulating layer I 41 is formed on the silicon substrate 2. The thermally conductive insulating layer I 41 is composed of a silicon nitride layer. The thermal conductivity of silicon nitride is very high. Generally, the thermal conductive glue is more than 100 times higher. At the same time, the thickness of the thermally conductive insulating layer I 41 is thin, so the thermal conductivity is good, and it can play a good role in heat conduction and heat dissipation. A...

Embodiment 2

[0072] Such as Picture 11 As shown, the high-on-voltage LED integrated chip with electrostatic protection of this embodiment includes several LED bare chips 1 and a silicon substrate 2. The LED bare chips 1 include sapphire (Al 2 O 3 ) The substrate 10 and the gallium nitride (GaN) N-type epitaxial layer 11 and the P-type epitaxial layer 12. Of course, the substrate 10 may also be a substrate made of other materials such as silicon carbide (SiC). 2 is a P-type silicon substrate. A thermally conductive insulating layer I 41 is formed on the silicon substrate 2. The thermally conductive insulating layer I 41 is composed of silicon dioxide. The thermal conductivity of silicon dioxide is higher, and its thermal conductivity is higher than that of ordinary The thermal conductive glue is several times higher. At the same time, the thickness of the thermally conductive insulating layer I 41 is thin, so the thermal conductivity is good, and it can play a good role in heat conduction and...

Embodiment 3

[0087] Such as Figure 22 As shown, the difference between this embodiment and the first embodiment is that in the high-on-voltage LED integrated chip with electrostatic protection in this embodiment, the LED bare chip 1 is a single-electrode chip, and the LED bare chip 1 includes arsenic. A gallium (GaAs) substrate 10, an N-type epitaxial layer 11, and a P-type epitaxial layer 12. Of course, the substrate 10 may also be a substrate of other materials such as silicon carbide (SiC), and each of the LED bare chips 1 is mounted On each of the metal layers 6 and connected through the metal layers 6 to form a full series circuit, the substrate 10 is bonded to the metal layer 6 with silver paste or tin, and the LED bare chip 1 The electrode contact is welded to the adjacent one of the metal layers 6 by a metal wire 41.

[0088] The remaining features of this embodiment are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com