Heat shield

A technology for heat shields and components, applied in the direction of mufflers, exhaust treatment, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

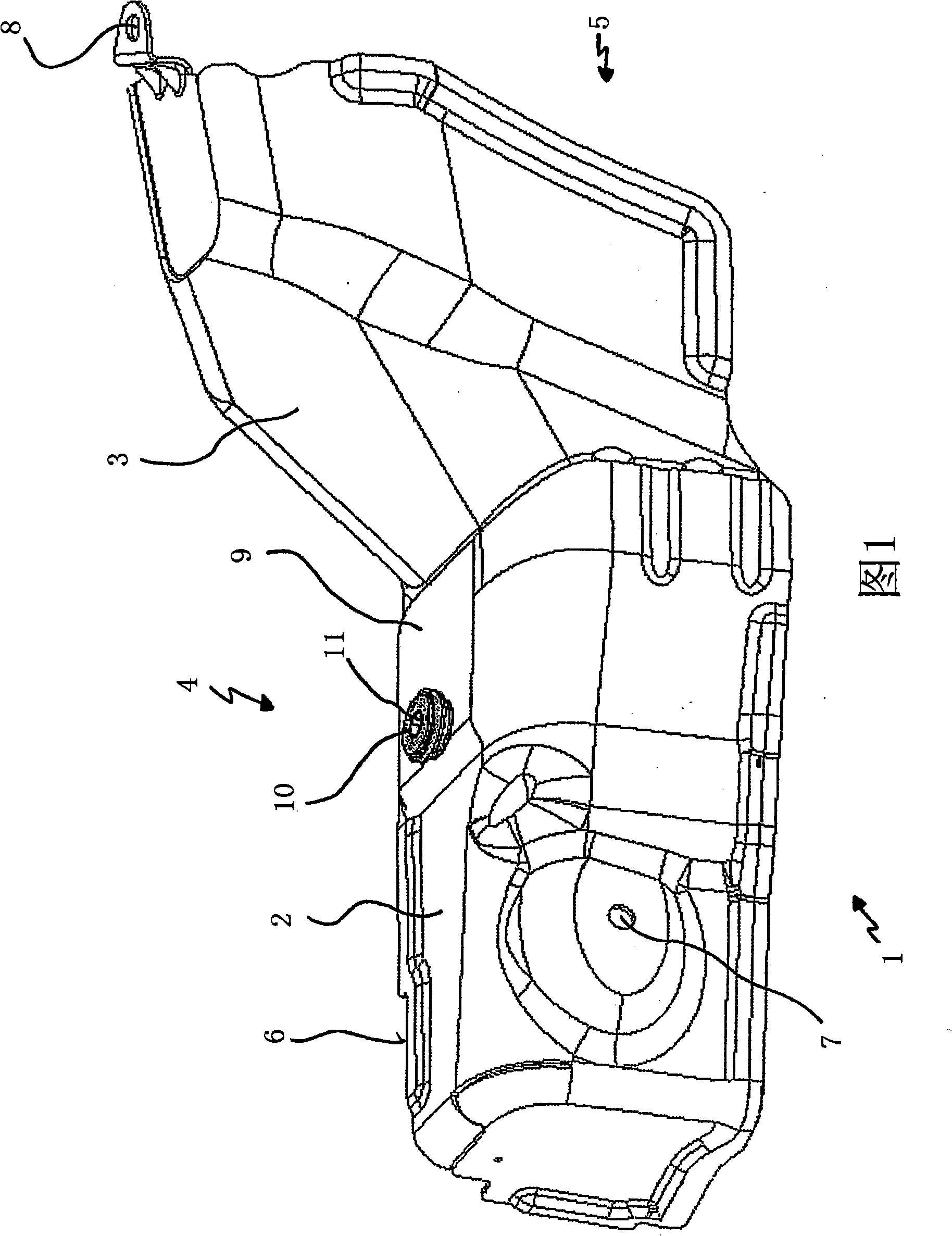

[0025] FIG. 1 shows a perspective view of a heat shield 1 which is intended to consist of two parts 2 , 3 in this exemplary embodiment. In this exemplary embodiment, the heat shield 1 also shields the exhaust manifold 4 , which is only schematically visible here. The exhaust manifold is a part of the exhaust system which can include, for example, an exhaust supercharger in the region 5 . It can be seen that the engine side of the exhaust manifold 4 has a connection region 6 which comprises a spatially complex structure in the direction of the region 5 . The individual components 2 , 3 are therefore also designed differently depending on the contour, that is to say they are approximately adapted to the spatial configuration of the exhaust manifold 4 . Part 2 has fastening regions 7 on exhaust manifold 4 , and part 3 has fastening regions 8 on exhaust gas supercharger 5 , by means of which they are fixedly movable relative to the structural part in question. Different temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com