Printer ink supplying bracket and ink supplying frame and system

A printer and ink supply technology, which is applied in printing and other fields, can solve the problems of high cost, short use time, and small ink capacity in boxes, and achieve the effects of improving utilization rate, simple replacement of ink, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

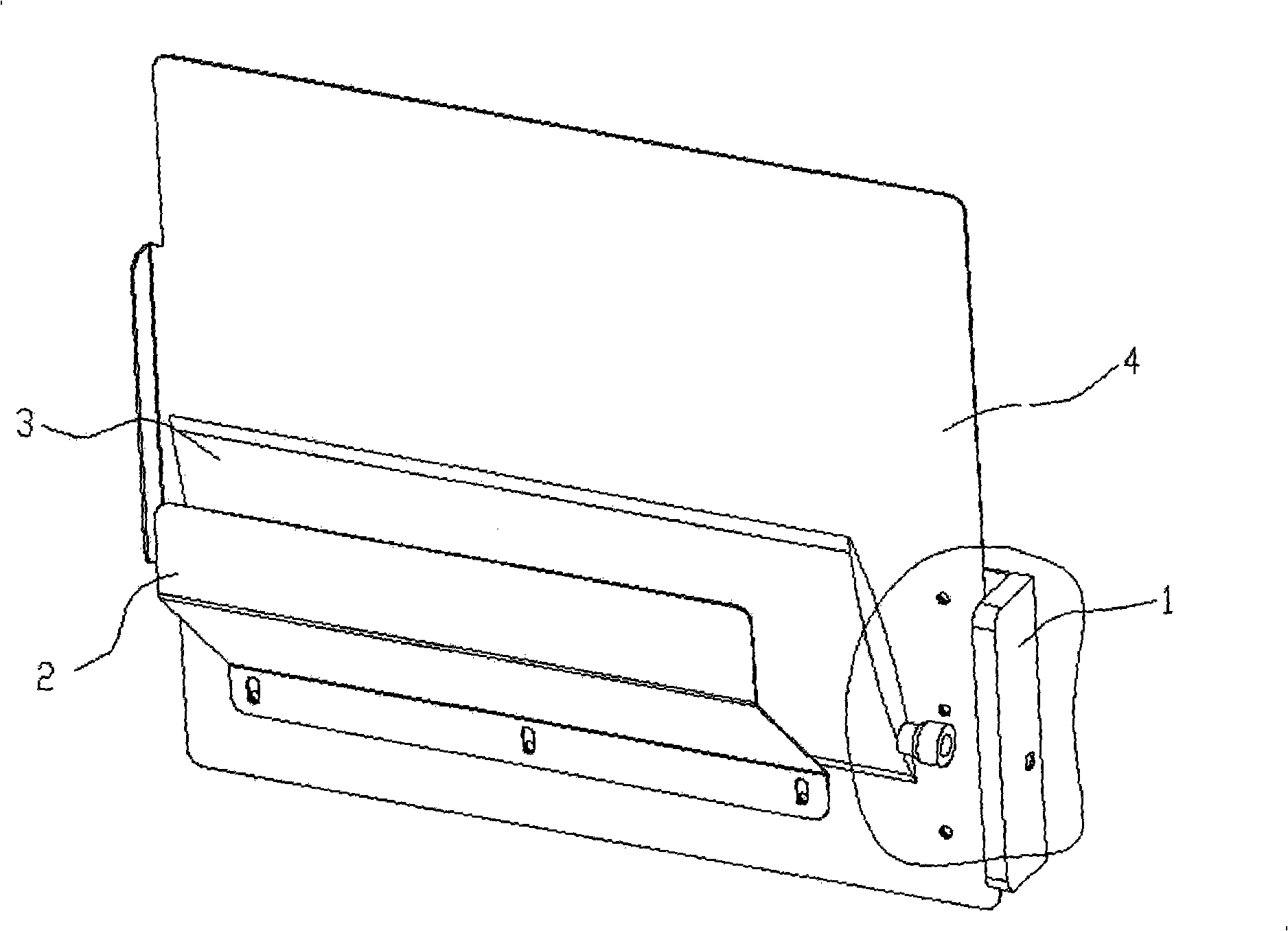

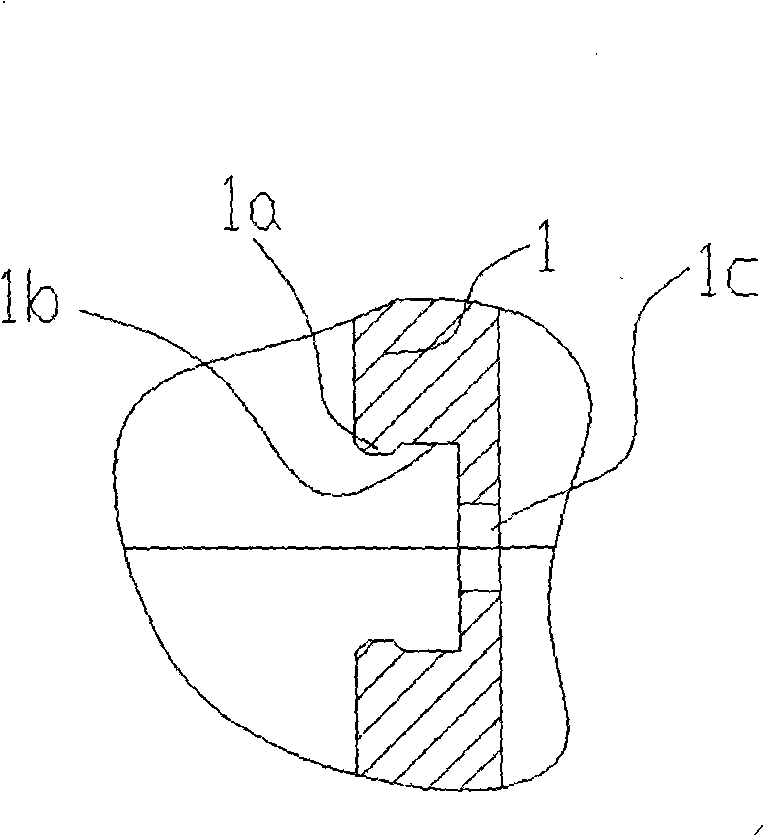

[0040] figure 1 It is a structural schematic diagram of an ink supply carriage according to an embodiment of the present invention, which includes an ink bag baffle 1 , an ink bag support 2 , an ink bag 3 , and an ink bag main board 4 . The ink bag baffle 1 is fixed on the ink bag main board 4, the inner side of the ink bag baffle 1 is provided with a groove 1b for accommodating the head of the ink bag 3, and the outer side is provided with a through hole 1c for the ink bag pin 19 to pass through. In order to effectively fix the head of the ink bag 3 in the groove 1b inside the ink bag baffle 1, a convex ring 1a can be provided on the wall of the groove 1b of the ink bag baffle 1 (such as figure 2 ) or a buckle is provided at the end of the groove 1b for clamping the head of the ink bag 3 .

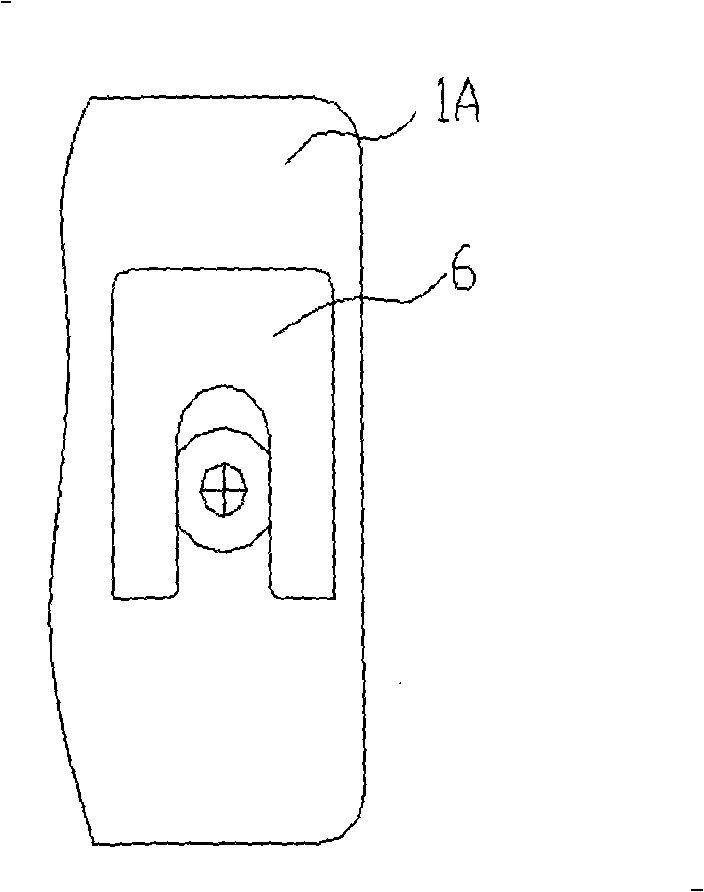

[0041] image 3 It is a schematic diagram of the assembly of the ink bag outer baffle and the ink bag cardboard of another embodiment of the ink supply carriage of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com