Container with transport structure and transport structure thereof

A container and mounting hole technology, applied in the field of container and automobile body transportation structure, can solve the problems of high transportation cost and low shipping efficiency, and achieve the effects of reducing labor intensity, improving shipping efficiency and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

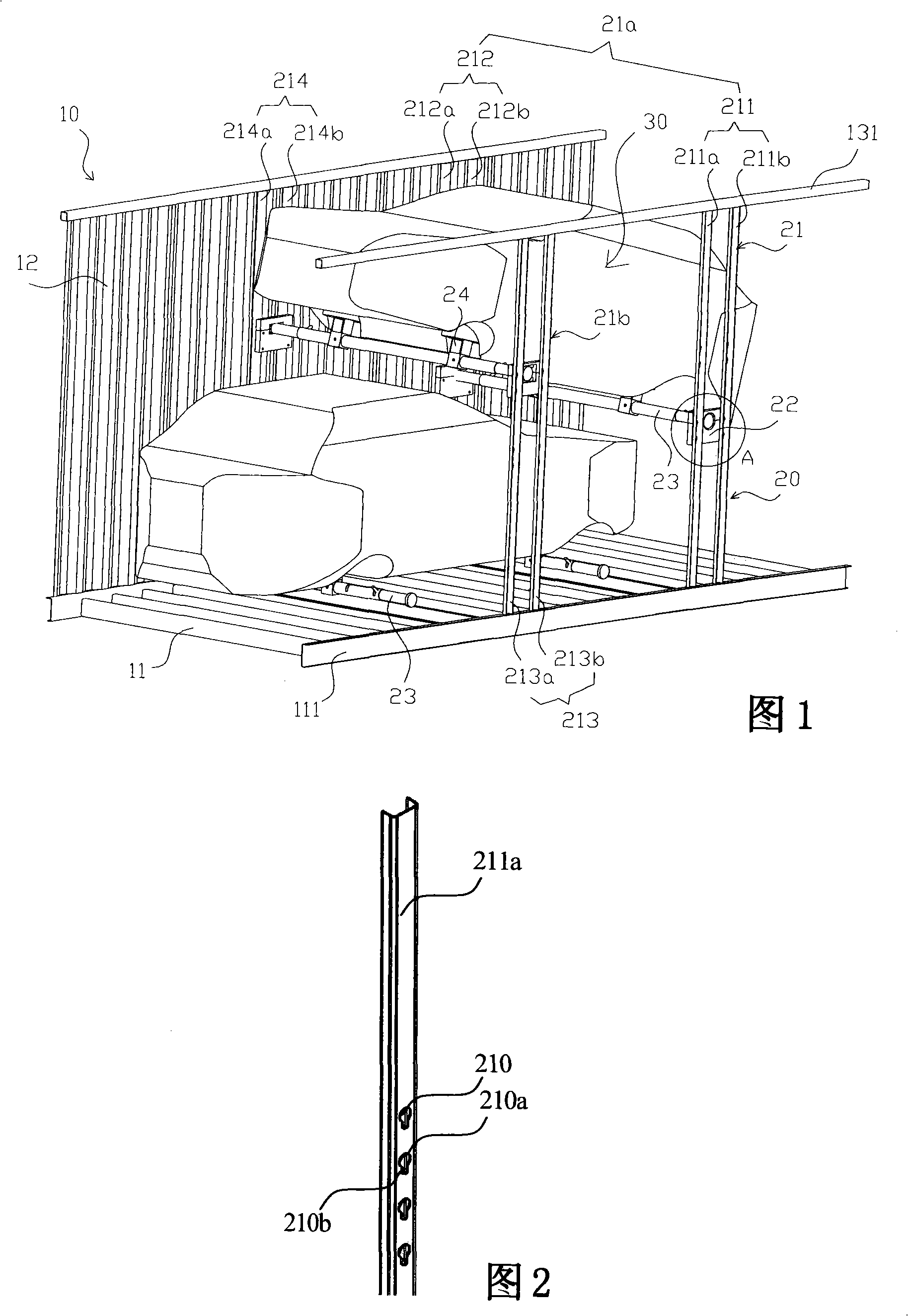

[0036]As shown in Figure 1, the container 10 with transportation structure of the present invention can be a standard container, comprises floor 11, top wall (not shown in the figure), side wall 12, door end and rear end wall (not shown in the figure) A box body is formed, and a transport structure 20 for transporting the vehicle body is arranged in the box body. Wherein, the transportation structure 20 includes: several groups of back beams 21 arranged at predetermined intervals on the side wall 12, for example, including a first back beam group 21a and a second back beam group 22b respectively arranged near the two ends of the container 10, Each back beam group 21a, 21b respectively includes two first back beam units 211, 213 and second back beam units 212, 214 oppositely arranged on the side wall 12, and each back beam unit is composed of at least one back beam 21, Preferably, in this embodiment, the back beam unit is composed of two back beams arranged at a predetermined d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com