Method for installing frock of glass nail column of automobile

A technology for automotive glass and installers, applied to positioning devices, manufacturing tools, metal processing equipment, etc., can solve problems such as low precision, inconvenient loading, and low efficiency, so as to improve production efficiency, product quality, and finished products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

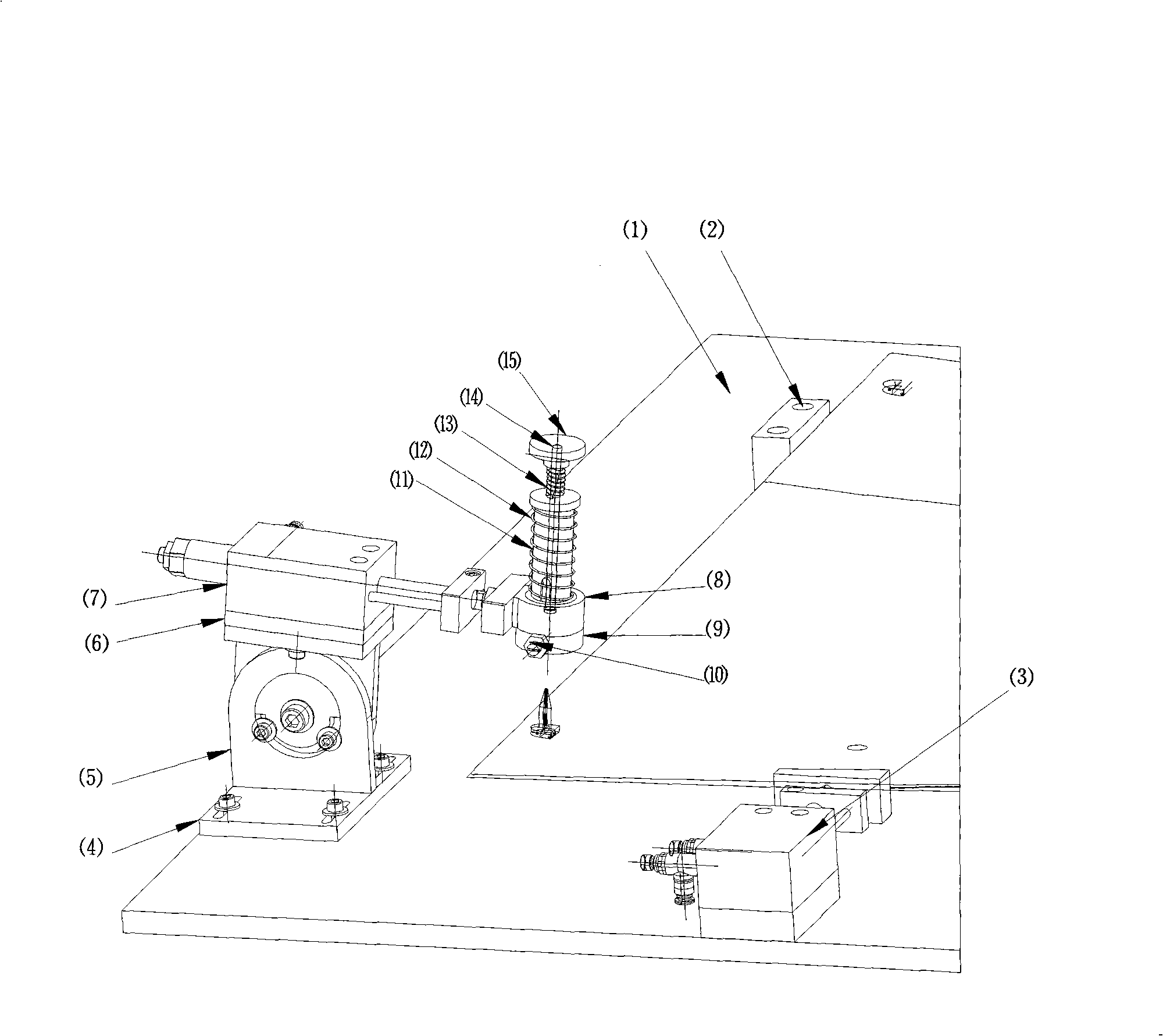

[0017] Such as figure 1 As shown in the figure, a design method for installing tooling for automobile glass studs, the production process is as follows: first place the glass on the tooling table, the positioning point of the tooling should be in the same direction as the positioning point of the inspection tool, and clamp the glass with a pneumatic device. Insert the stud into the stud cover, apply polyurethane glue on the position where the stud and the glass are attached, press the top of the device, the stud can be fixed on the glass, release the pneumatic device, remove the glass, and complete the installation.

[0018] Its characteristics are: 1. The same positioning point 2 as the inspection tool is used, so that no cumulative deviation will occur; 2. The positioning cylinder 3 is used to ensure that the glass is in place; 3. The adjustment base plate 4 and the adjustment plate 6 are designed as U-shaped groove base plates , you can adjust the position of the nail colum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap