Preparing process of gallium nitride based LED large power chip

A gallium nitride-based, preparation technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems that affect the photoelectric performance of gallium nitride materials, reduce the luminous efficiency of chips, and the metal reflective layer is easy to fall off, etc. Achieve the effects of reducing lattice damage, improving contact interface, and reducing light intensity attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

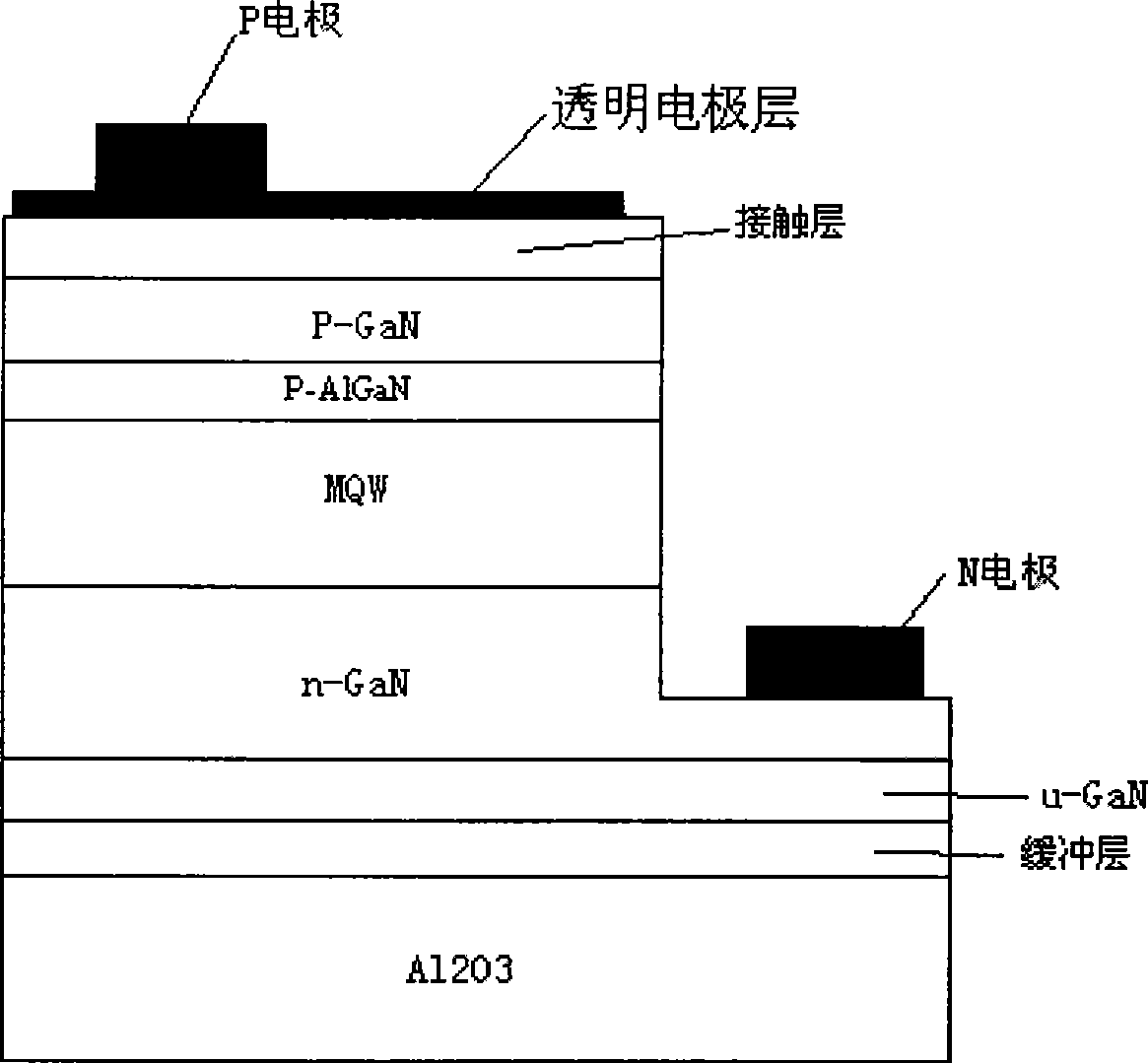

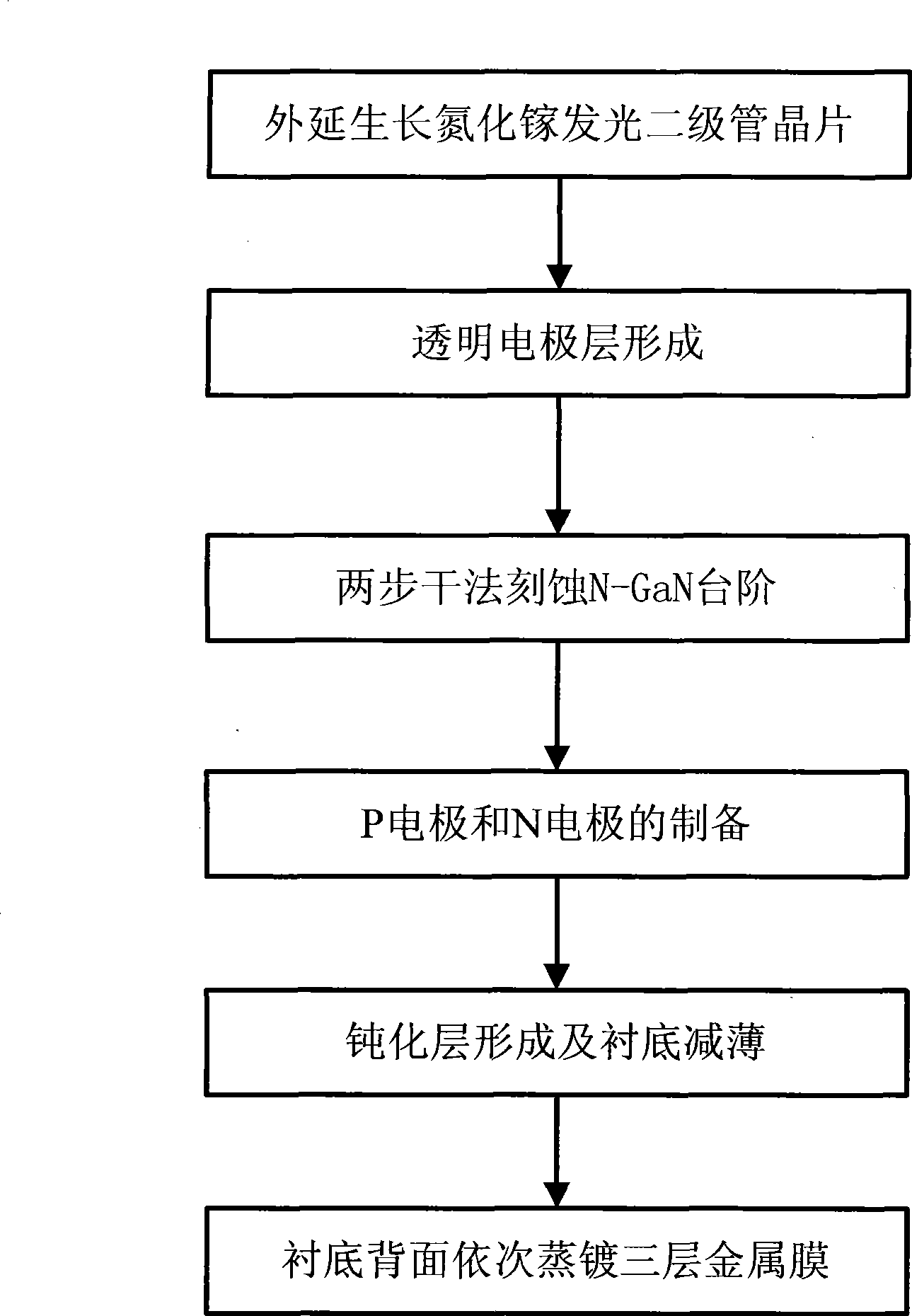

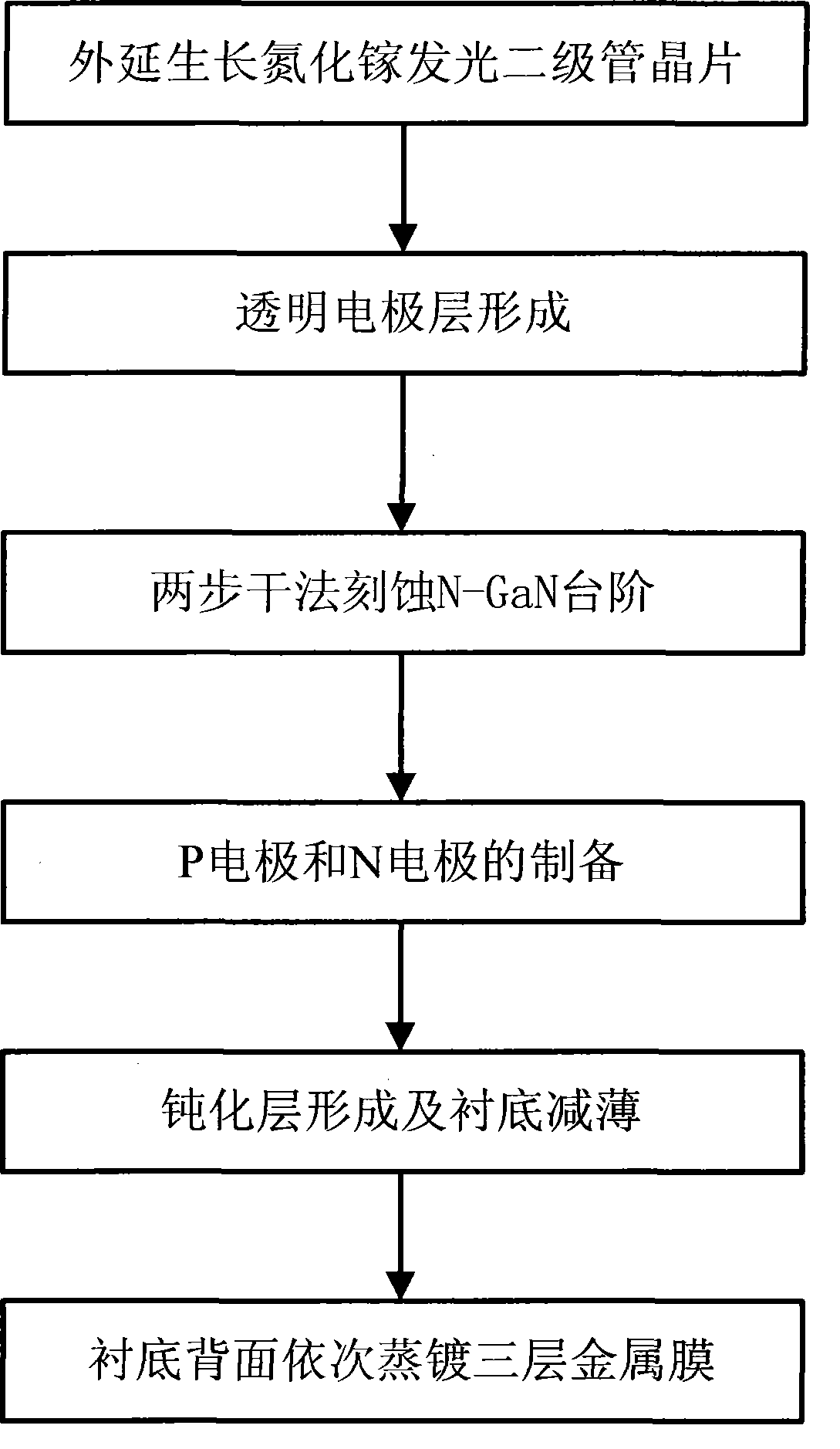

[0011] figure 2 It is the preparation process flow chart of the present invention, wherein the epitaxial growth of gallium nitride light-emitting diode wafer, formation of transparent electrode layer, preparation of P electrode and N electrode, formation of passivation layer and substrate thinning are the same as those of the prior art. The two-step dry etching process of the present invention comprises: the first step, adopts the mixed gas of Cl2 and Ar to carry out main etching, carves N-GaN step; The mixed gas of BCl3 and N2 enters the etching chamber to etch gallium nitride, and etch away the N-GaN layer with a thickness of about 0.05-0.15um. In this embodiment, an inductively coupled plasma reaction etching machine is used for etching. After the gallium nitride wafer is grown and the transparent electrodes are plated, the etching pattern is formed using photoresist and the wafer is sent into the etching chamber for further processing. Two-step etch process. The etching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com