Apparatus, system, and method for print quality measurements

A printing system and equipment technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve the problems of limited functionality, expensive, slow printing quality monitoring technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

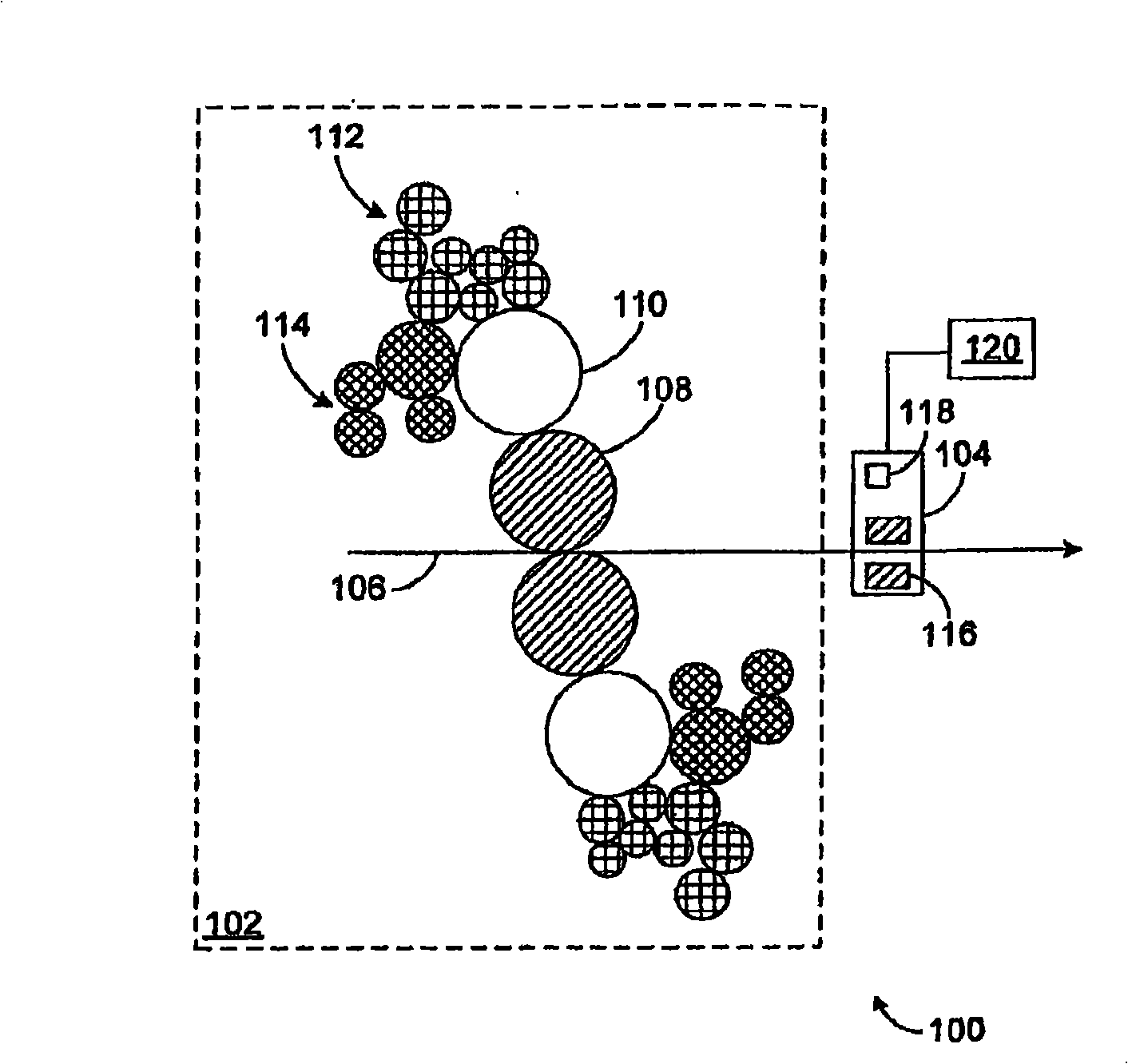

[0017] figure 1 An example system 100 for print quality measurement in accordance with an embodiment of the invention is described. exist figure 1 The embodiment of system 100 shown in is for illustration only. Other embodiments of system 100 may be used without departing from the scope of the present invention.

[0018] In this example, system 100 includes printing press 102 and print quality monitor 104 . The printer 102 is capable of printing content (such as text and images) on a substrate 106 (such as paper). In a particular embodiment, substrate 106 may represent paper or other material that is approximately three meters wide and moves through printer 102 at up to twenty meters per second or more.

[0019] In this particular example, printing press 102 represents a blanket-to-blanket press that includes two blanket cylinders 108, two plate cylinders 110, two Ink unit 112 and two dampening units 114 . The blanket cylinder 108 is capable of producing the actual print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com