Flexographic printing original plate and water-developable photosensitive resin laminate

A photosensitive resin layer, flexographic printing technology, applied in printing, printing process, optics, etc., can solve problems such as plate adhesion, achieve excellent solvent resistance and ink resistance, and inhibit the effect of excessive dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

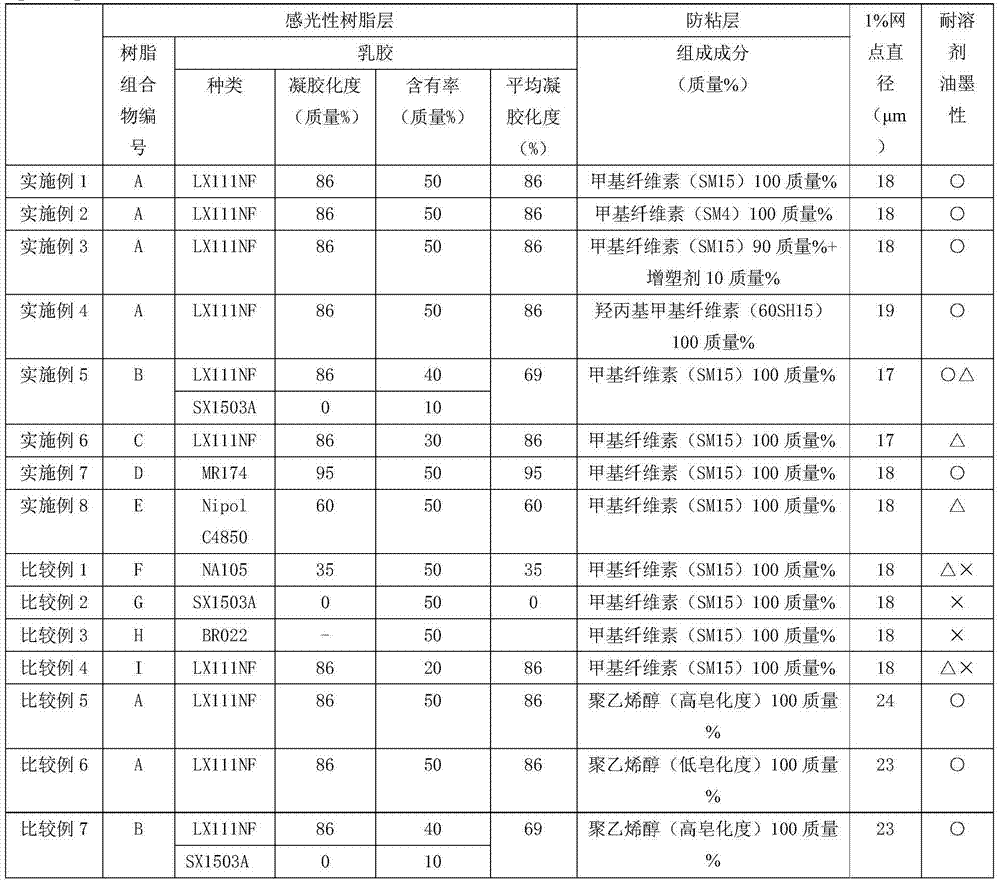

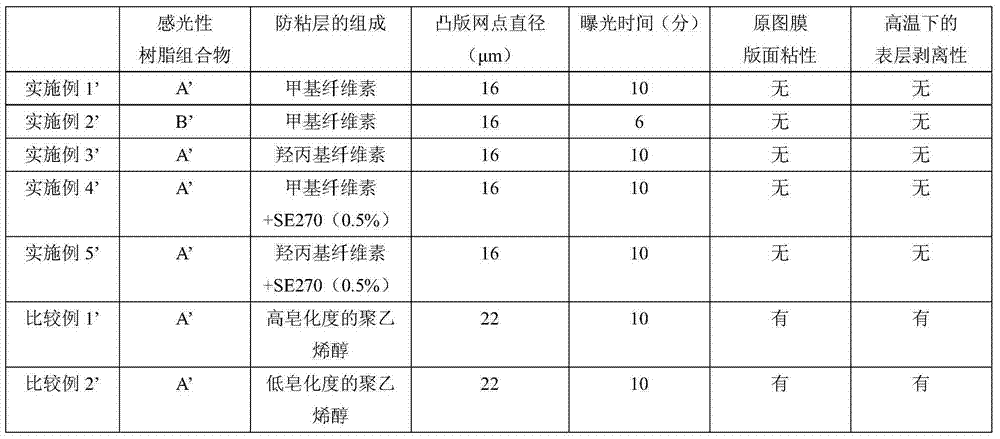

Examples

Embodiment 1

[0119] (Manufacturing of flexographic printing original plates)

[0120] After dissolving methyl cellulose (manufactured by Shin-Etsu Chemical Co., Ltd., SM15) in a mixed solvent of water and isopropyl alcohol, it is applied and dried on a matte PET film (thickness 100 μm) to obtain a release layer cover film. The thickness of the release layer is 1.2 μm. Then, the photosensitive resin composition described in Table 1 is arranged on the PET film carrier coated with the copolyester adhesive, and the cover film with the release layer is stacked thereon. Lamination was performed at 100°C with a hot press. A flexographic printing original plate formed of a PET carrier, an adhesive layer, a photosensitive layer, a release layer and a cover film is obtained. The total thickness of the plate is 1.7mm.

[0121] (manufacturing printing plates from flexographic printing masters)

[0122] First, in order to form the bottom layer, carry out a chemical line for 1 minute from the side o...

Embodiment 2

[0124] The same production and evaluation as in Example 1 were performed except that methyl cellulose (manufactured by Shin-Etsu Chemical Co., Ltd., SM4, low-viscosity type) was used as the anti-adhesive composition.

Embodiment 3

[0126] In addition to the methyl cellulose, a plasticizer (aliphatic polyol-based polyether polyol, SE270, manufactured by Sanyo Kasei) was added as an anti-adhesive composition, and the same manufacturing process as in Example 1 was carried out. Evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com