Modular conveyor belt with tight radius in one curve direction

A conveyor belt and modular technology, which is applied in the field of modular plastic conveyor belts and integrally molded modules, can solve the problems of no public and effective design, and achieve the effect of beam strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

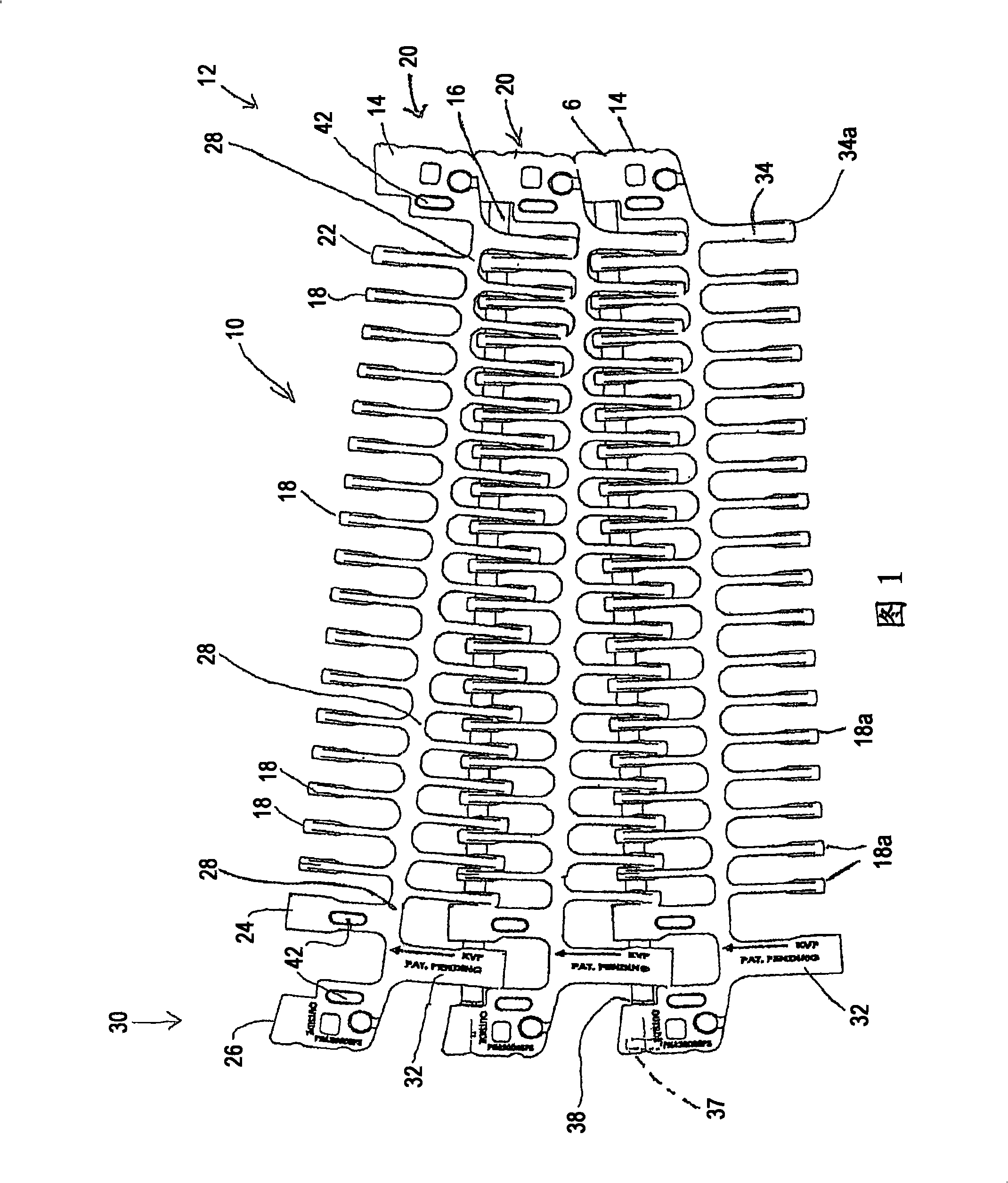

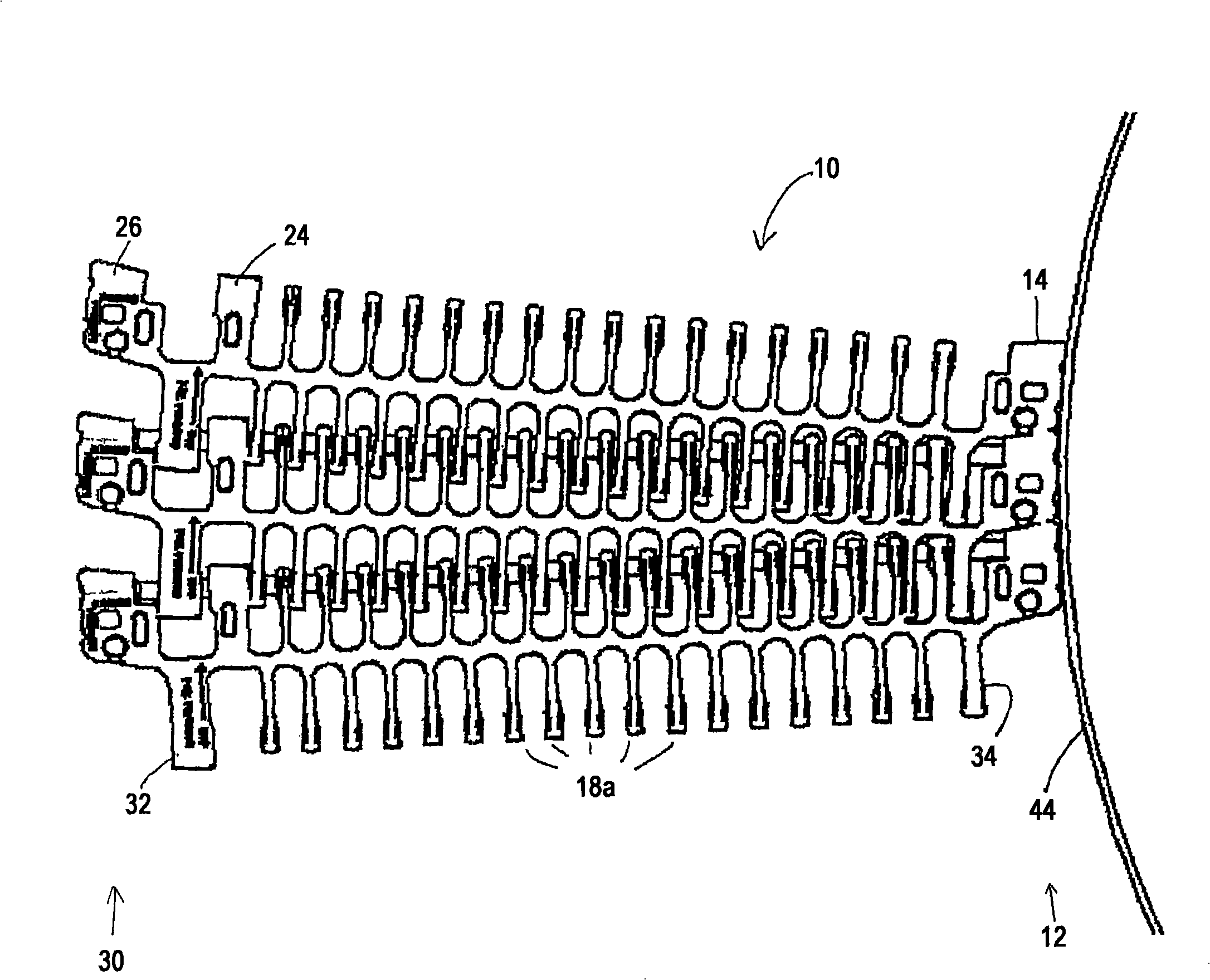

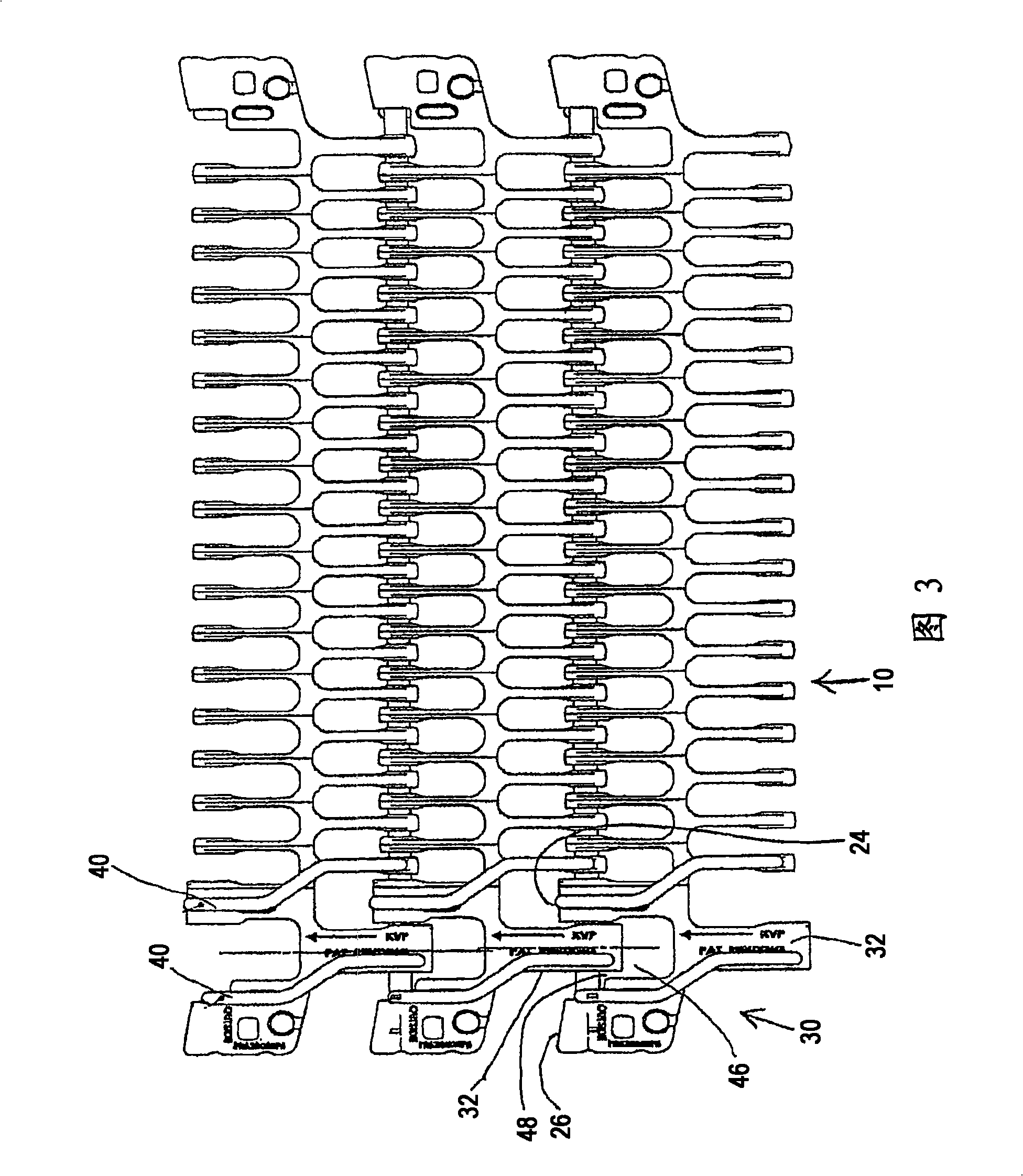

[0020] Figure 1 to Figure 4 A portion of a modular plastic radius conveyor belt 10 is shown. This portion of the belt is located on a bend in the main direction of turn, with its inner side 12 almost completely constricted. There are special inner edge link ends or joints 14 on the inner edge, each said link end or joint has an opening for a link 16, each said opening is connected to a large number of the first set of link ends on each module 20. The openings on the intermediate link ends or joints 18 are aligned. Link ends 18 (referred to herein as intermediate link ends) are narrow and relatively closely spaced together as shown. Immediately inside the middle link end is a wider, heavier link end 22 and at the innermost edge is said special wide edge link end 14 . Outboard of the middle link end 18 are thicker, wider and heavier link ends 24 and a special outer edge link end 26 which is similar in most respects to the special inner edge link end 14 . All of these link e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com